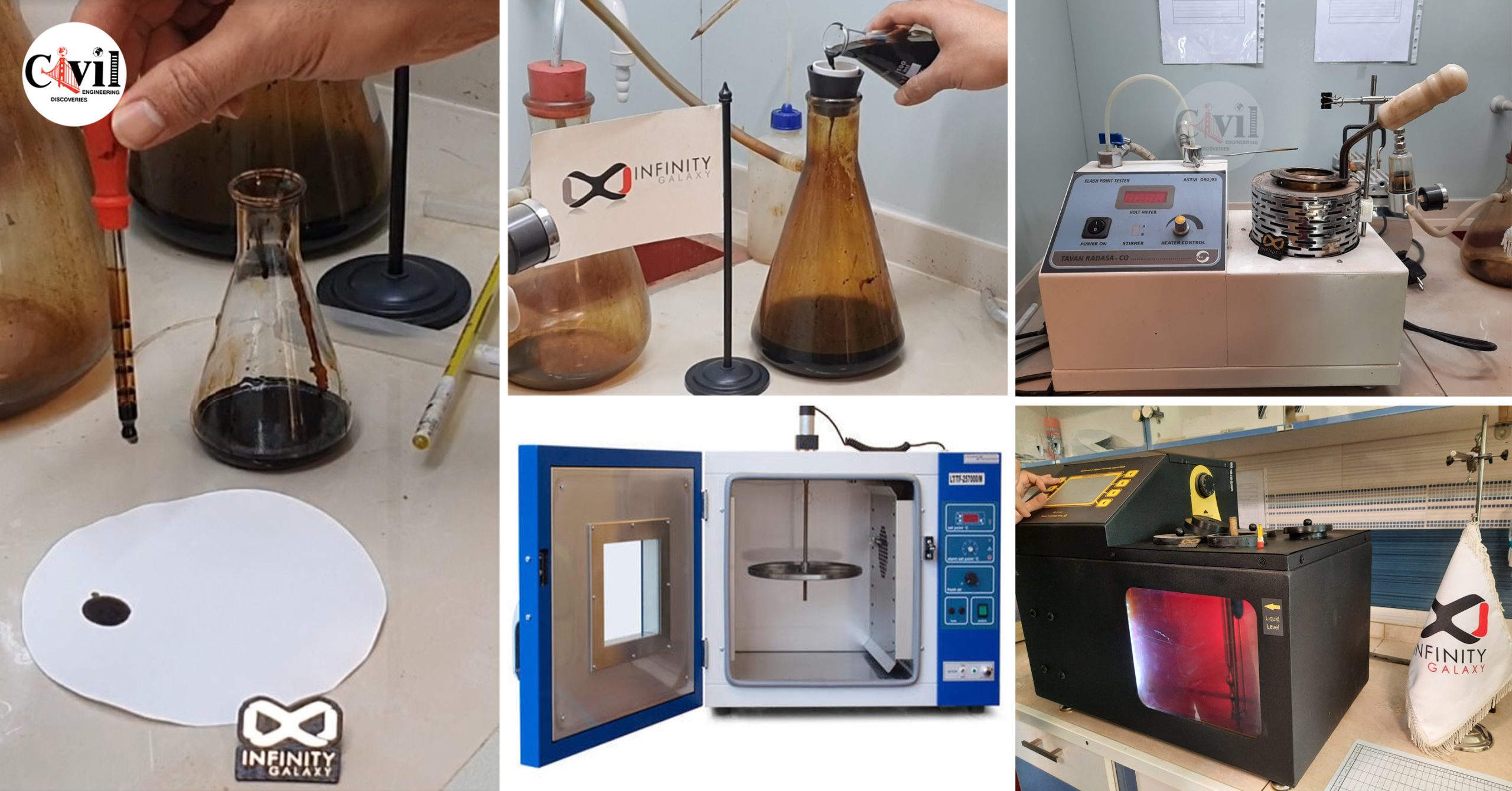

In road construction, bitumen is used as an adhesive material to stick the aggregates together and make a standard asphalt.

Some tests are designed to control the bitumen qualification.

They are used for:

- Grading bitumen

- Checking the bitumen consistency

- Measuring the bitumen impurity

- Checking the bitumen safety

Following are 10 of the most practical tests for pure bitumen, along with their importance and procedure:

1. Penetration Test of Bitumen

This test is performed with a needle that applies a load of 100 grams on the bitumen surface for 5 seconds. The amount of needle movement is reported as penetration in a tenth of a millimeter or deci-millimeter(dmm).

In the early twentieth century, the penetration test was introduced to the industry for grading bitumen based on its hardness and softness.

It classifies bitumen into different types such as:

- Penetration grade 40/50

- Penetration grade 60/70

- Penetration grade 80/100

For example penetration grade 80/100 means that the needle penetrates into the bitumen surface in the range of 80 to 100 dmm.

Based on this classification we can select the suitable bitumen for the climatic conditions of the region.

Harder types of bitumen are suitable for hot weather whereas softer types are suitable for cold weather.

Procedure:

At first, the bitumen sample must be heated at 75 to 100 ° C to become liquid.

Then pour the melted bitumen into the container. After the sample cools at room temperature, place it in the water bath at 25 ° C for about 2 hours.

Then place the sample under the penetrometer.

Apply the needle with a 100-gram load to the bitumen surface for 5 seconds and note the number.

Repeat the test at least three times then report the mean number as the penetration value.

2. Softening Point Test of Bitumen

This test is conducted for measuring the temperature at which bitumen becomes soft and starts to melt.

This temperature is crucial because at softening point bitumen starts to melt and the asphalt loses its stability.

Procedure:

The standard method for measuring the softening point is “ring and ball”.

To conduct the test, cover the plate on which the rings are to be placed with a mixture of glycerin and dextrin. This is to prevent the bitumen from sticking to the surface.

Fill two heated brass rings with melted bitumen. The bitumen sample should be a little over the volume of the rings.

After they became cool at room temperature, cut the extra bitumen with a hot knife.

Then place the rings on the stand in the beaker, then place the whole assembly in the water bath at 5 °C. Put two steel balls on top of the rings.

After reaching temperature equilibrium place the beaker on the heater.

The temperature at which the steel ball coated with bitumen hits the bottom of a glass beaker is the softening point.

3. Ductility Test of Bitumen

The ductility test measures the amount of stretched length of bitumen sample at 25 ° C.

A suitable bitumen should be ductile in order to resist cracking as a result of temperature changes and traffic loads.

Procedure

To perform this test, pour the melted bitumen into the mould. Be sure that the bitumen exceeds the mold’s volume.

Before the pouring sample coat the brass plate on which the rings are to be placed with a mixture of glycerin and dextrin. It prevents sticking the bitumen.

After the mould and brass plate cool at room temperature, place them in a water bath at 25 ° C.

After reaching temperature maintenance, remove them and cut the excess amount of bitumen with a hot knife.

Then Without applying any force, place the mould assembly in the water bath and attach the mould clips to the machine.

Start the machine and pull the clips from each other with a constant speed of 50 mm per minute.

Ductility is the length at which the bitumen thread stretches and then ruptures.

4. Viscosity Test of Bitumen

The viscosity test measures the resistance of bitumen against flowing. It is used for:

- Grading bitumen

- Choosing suitable bitumen for the desired climatic condition

The viscosity of bitumen must not be so high because it can not coat the aggregates well.

Also, it must not be so low, because it can not stick to the aggregates well.

Temperature changes affect viscosity. In India’s Standard, viscosity is measured at two temperatures of 60 ° C and 135 ° C. As a result we can have sufficient information about the best temperature of mix and compact bitumen with aggregates.

There are many types of apparatus to measure the bitumen viscosity. Here we introduce the cup viscometer method. This apparatus has different types according to the size of the drain hole (orifice).

Procedure

In the first step, you should heat the bitumen at about 20 °C over the test temperature.

After it becomes cool to the test temperature, pour 50 gr of it into the test cup.

Place the thermometer in the center of the sample cup. For 5 minutes, the apparatus should remain at the test temperature.

Open the valve and when the cylinder reading reaches 25 ml, start the stopwatch until it reaches 75 ml. Then stop the stopwatch and note the time in seconds.

Repeat the test several times and report the mean value as viscosity.

5. Specific Gravity Test of Bitumen

Specific gravity measures the ratio of bitumen weight to the weight of the water with the same volume.

Each bitumen has a specific gravity. As a result, it is an important factor to recognize impurity. It reduces the quality of the bitumen binder.

Procedure

To perform the test, the following amount should be measured:

A= mass of pycnometer

B= mass of the pycnometer that is filled with water

C= mass of pycnometer about half-filled with the bitumen

D = mass of the pycnometer about half-filled with the material and the rest with distilled water

E = mass of the pycnometer filled with the bitumen.

Finally to calculate the specific gravity, use the below equations:

- For solid and semi-solid bitumen:

Specific gravity= (C-A)/[(B-A)-(D-C)]

- For liquid bitumen:

Specific gravity=(E-A)/(B-A)

6. Solubility Test of Bitumen

The solubility test is a way to recognize the solubility of bitumen in organic solvents.

On the other hand, it helps us to measure inorganic impurity. This is important because impure bitumen reduces the quality and lifespan of asphalt.

Procedure

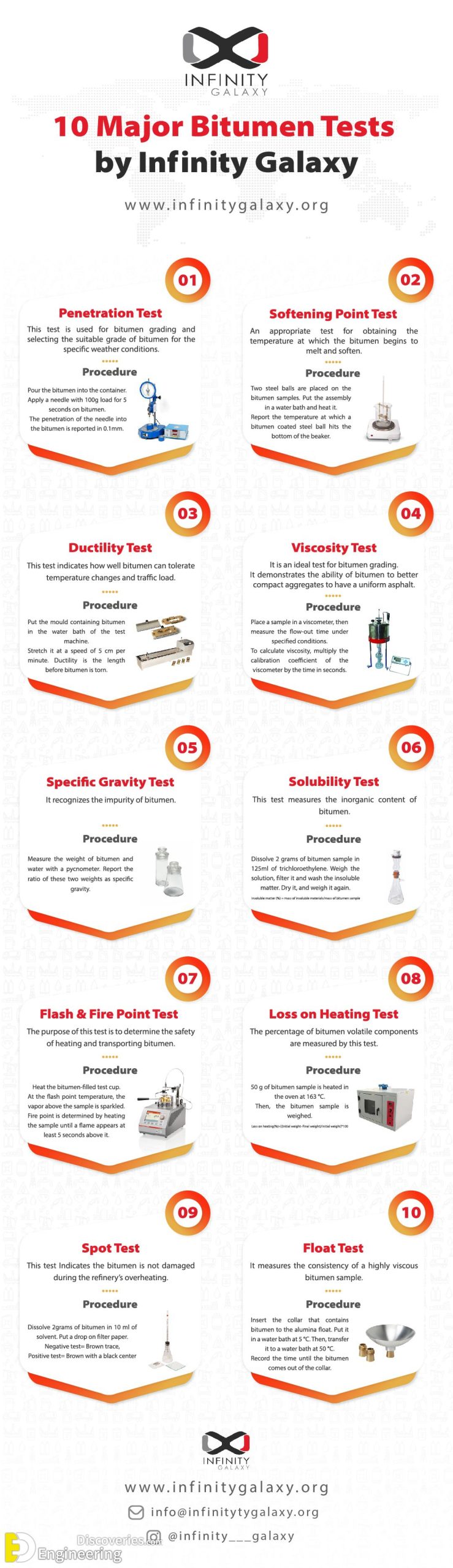

To perform this test you should heat the bitumen until it is completely liquified. Then place the 2g of it to the container and add 125 ml solvent.

The most usable solvent is trichloroethylene.

Weight the solution then start to filter it 15 minutes later. At this step, you should Place the gooch crucible in the filtering tube.

It is necessary to wet the glass fiber pad with trichloroethylene.

The solution drains through the glass fiber.

Wash the insoluble matters with trichloroethylene until the solvent becomes colorless.

After they become dry, weigh them.

The percentage of insoluble material calculate as follows:

Insoluble matter (%)= mass of insoluble materials/mass of bitumen sample

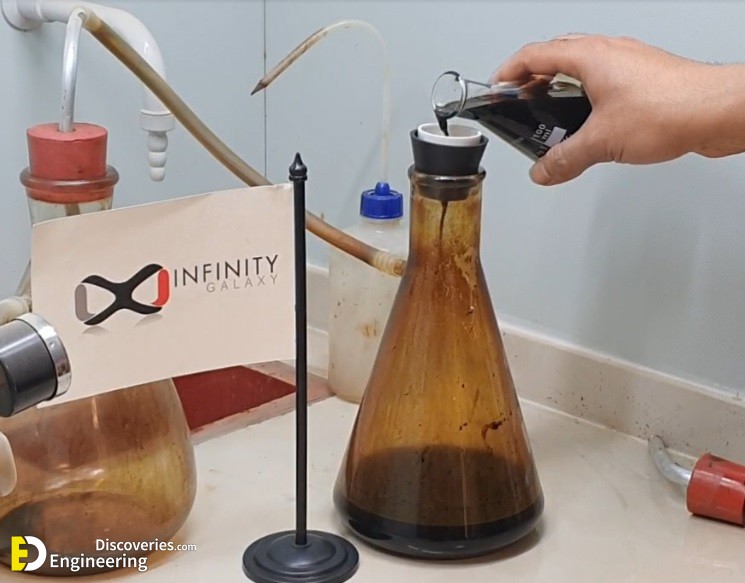

7. Loss on Heating Test of Bitumen

The loss on heating test of bitumen is conducted to measure the volatile content of bitumen.

If a bitumen binder has a high amount of volatile content it hardens over time. It is a negative point because the bitumen binder is not durable enough against the temperature changes and traffic load.

The amount below 1% is acceptable.

Procedure:

To perform the test you should put 50 g of bitumen in the container.

If the sample is solid, heat it to become liquid.

After the sample cools at room temperature weigh it.

Then place it in the oven at 163 ° C for 5 hours.

Thereafter remove the container and let it cool at room temperature. Weight it and use the following formula:

Loss on heating (%) = [(Initial weight – Final weight)/Initial weight]*100

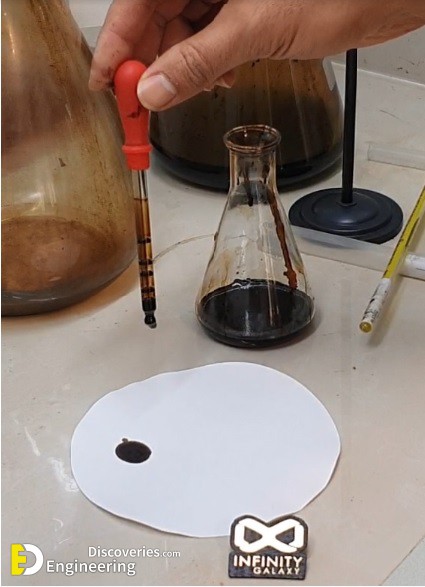

8. Spot Test of Bitumen

The spot test of bitumen is a way to recognize whether the bitumen is damaged by the high temperature or not.

High temperatures cause cracking and as a result, the consistency of bitumen and its stickiness becomes lower.

This test is reported qualitatively with a positive or negative answer.

A positive test indicates damage and a negative test shows no damage.

Procedure:

Place 2 g of bitumen sample in the container. Add 50 ml Xylene and 50 ml Heptane as solvents.

Place the container in the boiling water until the bitumen completely dissolves in the solvent.

Then place it in the water bath at 32 ° C for 15 minutes.

After that, put a drop of solution on the filter paper.

If the trace of the drop is brown with a black center the test result is positive.

On the other side, if the trace of the drop is completely brown or yellowish-brown the test must be repeated.

For this reason, let the sample rest for 24hr. Then place it again in the water bath at 32 ° C.

Again place a drop of solution on the filter paper.

If the trace of the drop is brown with a black center the test result is positive.

As opposed to that, if the drop is completely brown or yellowish-brown, the test result is negative.

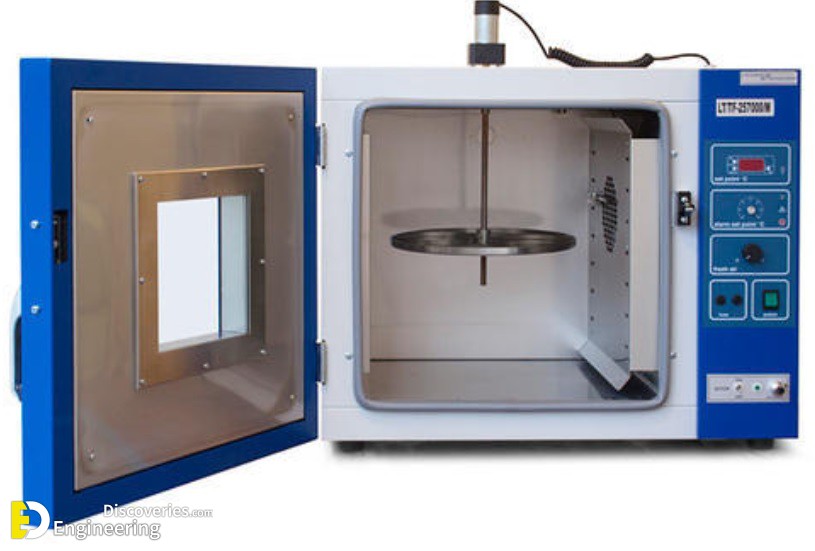

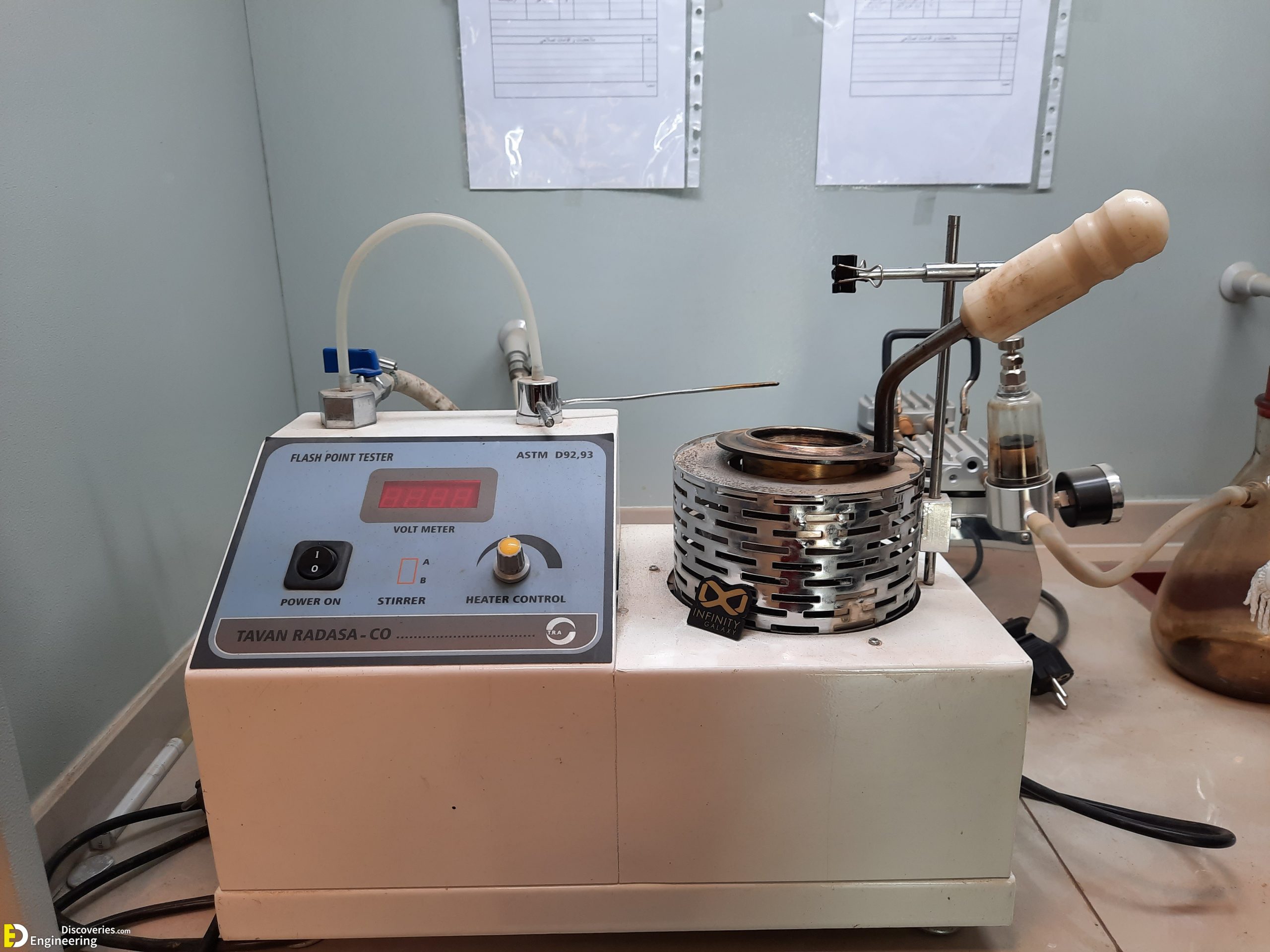

9. Flash and Fire Point Test of Bitumen

The flashpoint and fire point test of bitumen help us to assess its safety during applications, storage, and handling.

When the temperature rises the volatile component of bitumen accumulates near the surface of it. In the presence of an ignition source, it burns with an instant flame. This temperature is a flashpoint.

As the temperature rises, the bituminous material begins to burn under the influence of an ignition source, which is the fire point.

Procedure:

For measuring with a Cleveland open cup tester, pour the melted bitumen into the test cup until the filling line.

As the thermometer is in the test cup, apply the heat.

The temperature rise rate of the sample should be 5-17 °C.

If the material has a low flash point or is highly viscous, a heating rate should be 5 to 6 °C per minute from the beginning of the test to the end.

56 °C below the flashpoint temperature the rate of rising temperature is between 5 and 6 °C.

At 28 °C below the expected flashpoint, apply the test flame to move. Every time the sample temperature rises by 2 °C, the test flame must pass over the sample.

The temperature sample vapor ignites with an instant flame is a flashpoint.

To reach the fire point, the temperature continues heating to see the flame over the surface of bitumen which maintains at least for 5 seconds.

10. Float Test of Bitumen

The consistency of bitumens with high viscosity is measured with a float test of bitumen.

Bitumen binder with a proper consistency causes a uniform asphalt with decreasing risk of cracking on it.

Procedure:

Put the collar from the small end on the brass plate which is a coat with an equal value of glycerin and dextrin.

Pour the melted bitumen sample into the collar.

After reaching room temperature, place them in a water bath at a temperature of 5 ° C for about 15 minutes.

Heat the water bath until its temperature reaches 50 °C and maintain it.

Remove the collar from the brass plate then screw the collar to the alumina float.

Immerse the assembly in a water bath of 5 °C for 1 minute. The float must not have water.

Place the assembly in the water bath at 50 °C.

Calculate the float value by recording the time until the water breaks through the material.

An overview of the bitumen tests is provided in the following infographic:

Source: Infinity Galaxy

Click Here To See How To Calculate Asphalt Quantity For Road