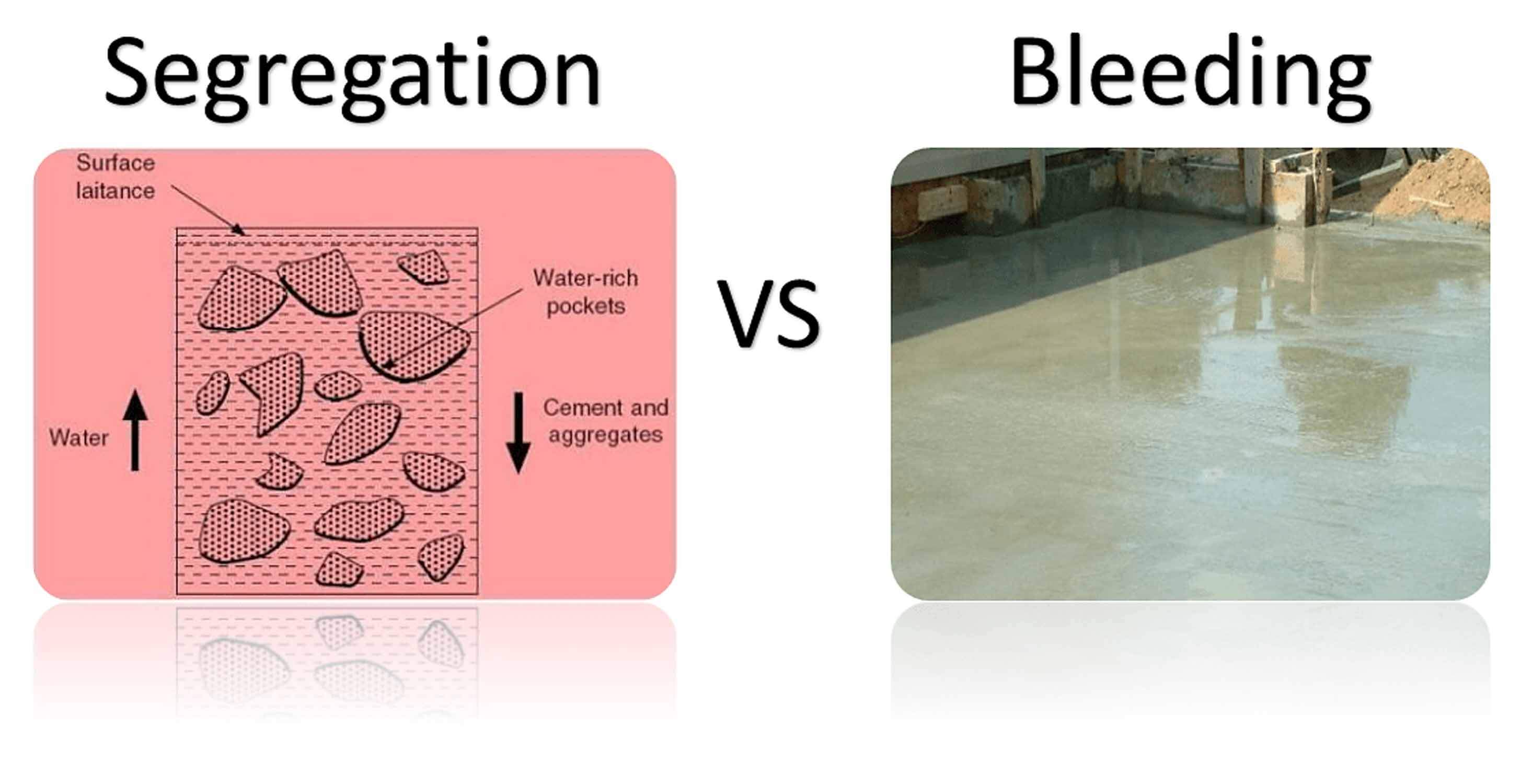

Segregation

Segregation can be defined as the separation of the constituent materials of concrete. A good concrete is one in which all the ingredients are properly distributed to make a homogeneous mixture. If a sample of concrete exhibits a tendency for separation such concrete is not only going to be weak; lack of homogeneity is also going to induce all undesirable properties in the hardened concrete but it can be controlled by the choice of suitable grading and care in handling. There are considerable differences in the sizes and specific gravities of the constituent ingredients of concrete. Therefore, it is natural that the materials show a tendency to fall apart.

Types of Segregation

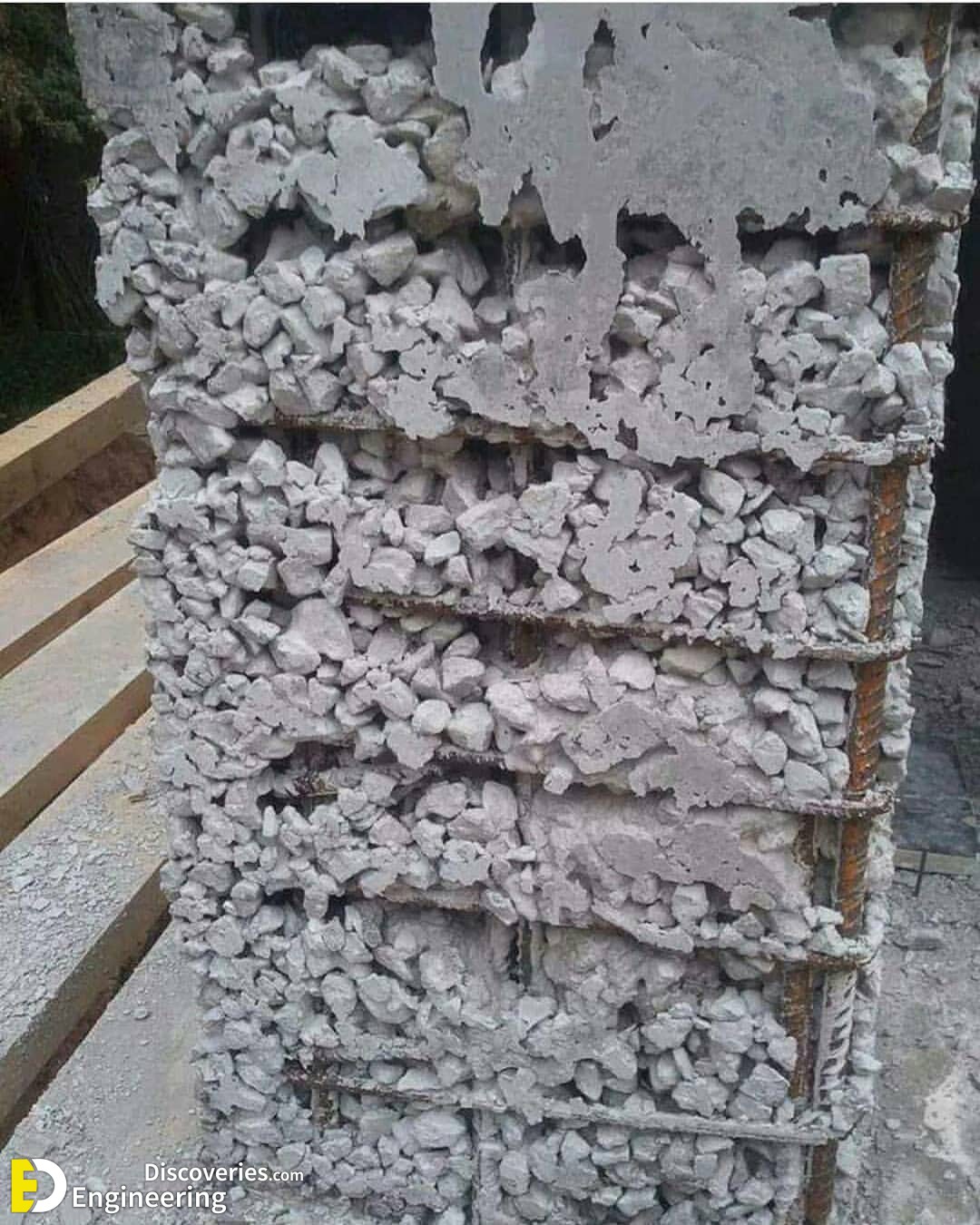

1- firstly (in too dry mixes), the coarse aggregate separating out or settling down from the rest of the matrix.

2- secondly ( in too wet mixes ), the paste or matrix separating away from coarse aggregate. if segregation is observed, remixing for a short time would make the concrete again homogeneous.

3- And lastly, Some amount of water isolating from the entire concrete paste being a material of the lowest specific gravity.

Causes of segregation

1- Transporting concrete mixes for long distance

2- Badly proportioned mix where sufficient matrix is not there to bind the aggregates

3- Dropping concrete from height places.

4- Vibrating concrete for long time.

the tendency for segregation can be remedied by correctly proportioning the mix, by proper handling, transporting, placing, compacting and finishing , using air entraining admixture and pozzolanic materials, and choosing coarse and fine aggregate with approach specific gravity.

Bleeding

Bleeding is sometimes referred as water gain. It is a particular form of segregation, in which some of the water from the concrete comes out to the surface of the concrete, being of the lowest specific gravity among all the ingredients of concrete. Bleeding is predominantly observed in a highly wet mix, badly proportioned and insufficiently mixed concrete. In thin members like roof slab or road slabs and when concrete is placed in sunny weather show excessive bleeding Due to bleeding, water comes up and accumulates at the surface.

Sometimes, along with this water, certain quantity of cement also comes to the surface. When the surface is worked up with the trowel and floats, the aggregate goes down and the cement and water come up to the top surface. This formation of cement paste at the surface is known as “Laitance”.

Water while traversing from bottom to top, makes continuous channels. If the water cement ratio used is more than 0.7, the bleeding channels will remain continuous and un segmented by the development of gel. These continuous bleeding channels are often responsible for causing permeability of the concrete structures.

While the mixing water is in the process of coming up, it may be intercepted by aggregates. The bleeding water is likely to accumulate below the aggregate.

This accumulation of water creates water voids and reduces the bond between the aggregates and the paste. The above aspect is more pronounced in the case of flaky aggregate. Similarly, the water that accumulates below the reinforcing bars, particularly below the cranked bars, reduces the bond between the reinforcement and the concrete. The poor bond between the aggregate and the paste or the reinforcement and the paste due to bleeding can be remedied by re vibration of concrete.

The bleeding is not completely harmful if the rate of evaporation of water from the surface is equal to the rate of bleeding which increase strength.

How to reduce bleeding

1- Proper proportioning and uniform and complete mixing.

2- Use of finely divided pozzolanic materials and air-entraining agent.

3- Use of finer cement or cement with low alkali and high C3A content.

4- Use Rich mixes which are less susceptible to bleeding.

For more information watch this video