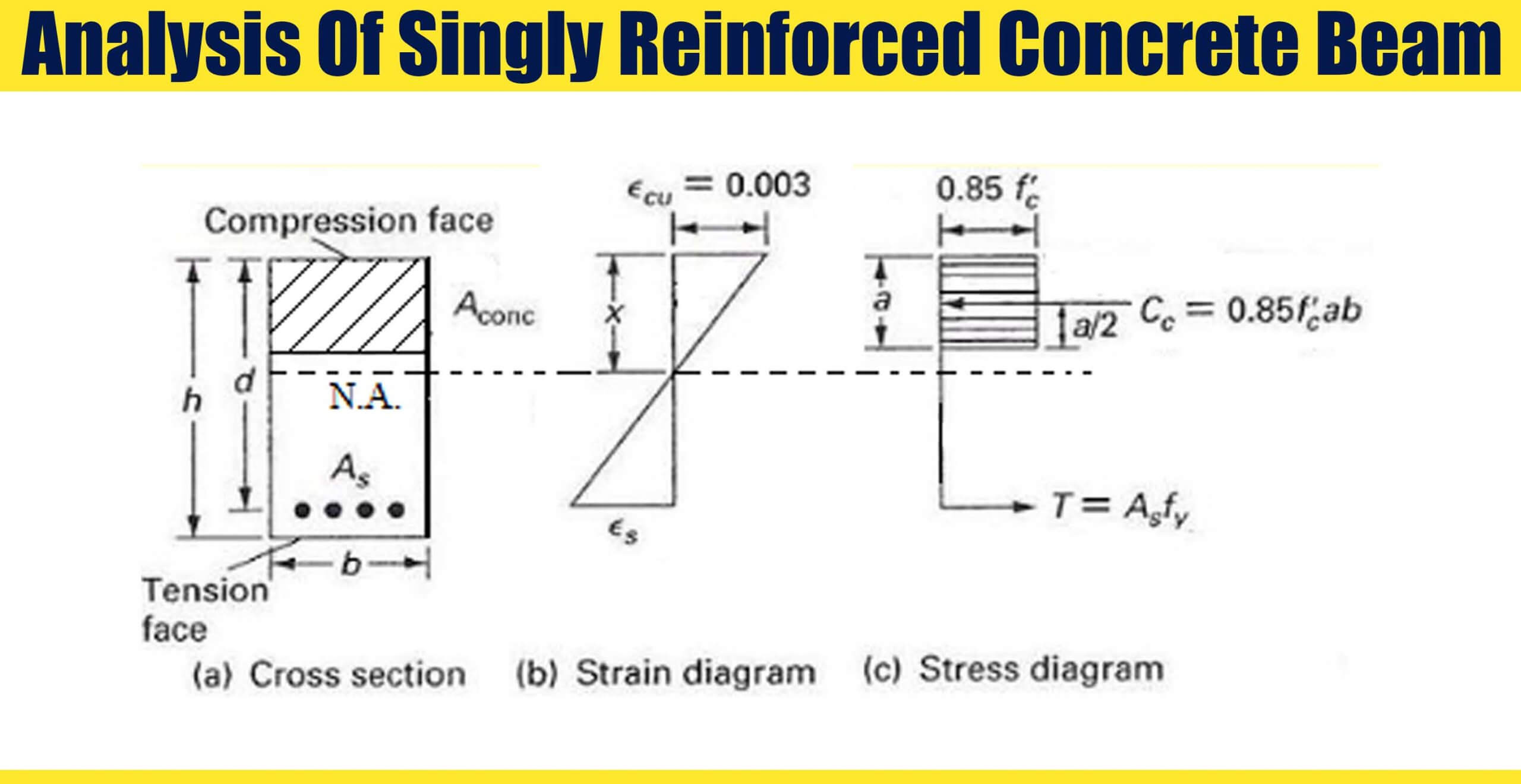

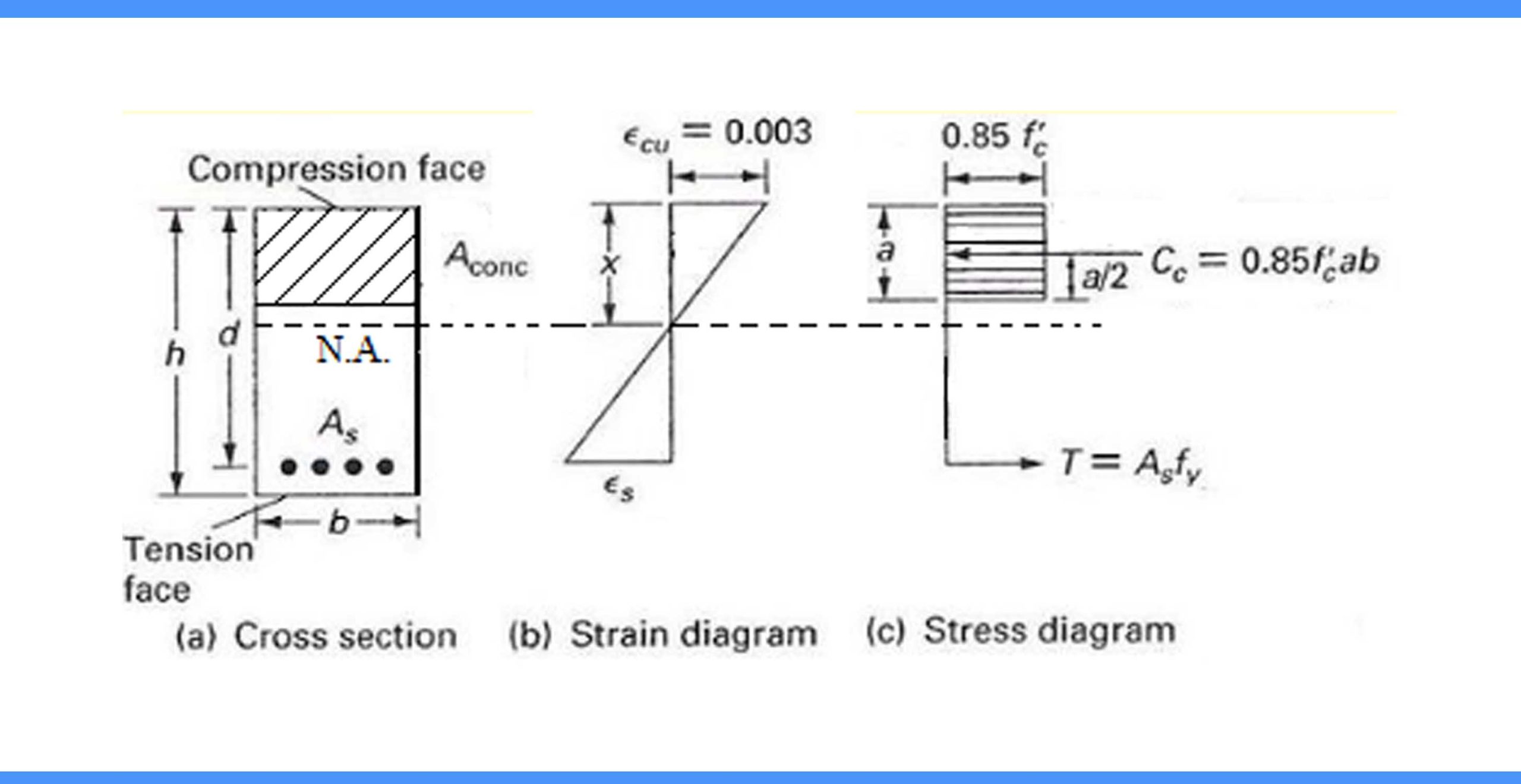

Concrete is weak in tension therefore steel is added in the tension zone of the section to provide strength in tension. The figure given below shows a typical section of the singly reinforced concrete beam with strain distribution and equivalent stress distribution (proposed by Whitney).

The actual stress distribution of concrete is parabolic. Whitney (1930) proposed an equivalent rectangular stress distribution, which is adopted by ACI – 318. This rectangular stress block has made the calculations easy It has average stress of 0.85fc and the depth “a” equal to β1, times neutral axis of the section. The value of β1 is taken as 0.85 for fc′ up to 4000 psi (30 MPa), and 0.05 less for each 1000 psi (7 MPa) of fc′ in excess of 4000 psi (30 MPa), but not less than 0.65

The nominal moment strength is obtained by applying static equilibrium and compatibility of stress and strain. The design strength is calculated by dividing nominal strength by strength reduction factor φ (phi).

With reference to the equivalent stress diagram as per Whitney

Force of tension due to tension rebar

T = (area tension rebar) (stress of steel)

T= As fy

It is required that tension-steel has yielded when failure takes place. This makes sure that the section is not controlled by concrete.