Lap length in reinforcement bars is crucial for ensuring the structural integrity of concrete constructions. Reinforcement bars, or rebars, provide tensile strength to concrete, which is inherently weak in tension. The purpose of the lap length is to provide a strong and continuous transfer of forces between two pieces of steel rebar. In this article, we’ll explore everything you need about lap length.

Why Is Lap Length Important in Construction?

The lap length ensures that when two rebars are joined, they act as a single continuous element. This is essential for maintaining the strength and stability of the structure. If the lap length is too short, the bond between the two rebars may not be strong enough to transfer loads, potentially leading to structural failures. On the other hand, excessive lap length wastes materials and increases costs unnecessarily.

Types of Lap Lengths

There are different types of lap lengths depending on the position of the bars:

- Tension Lap Length: This is the length required when the bars are in tension. Due to the nature of the tensile forces acting on the bars, it is typically longer than compression lap length.

- Compression Lap Length: This is the lap length required when bars are in compression. It is generally shorter than the tension lap length.

Standard Formula for Lap Length Calculation

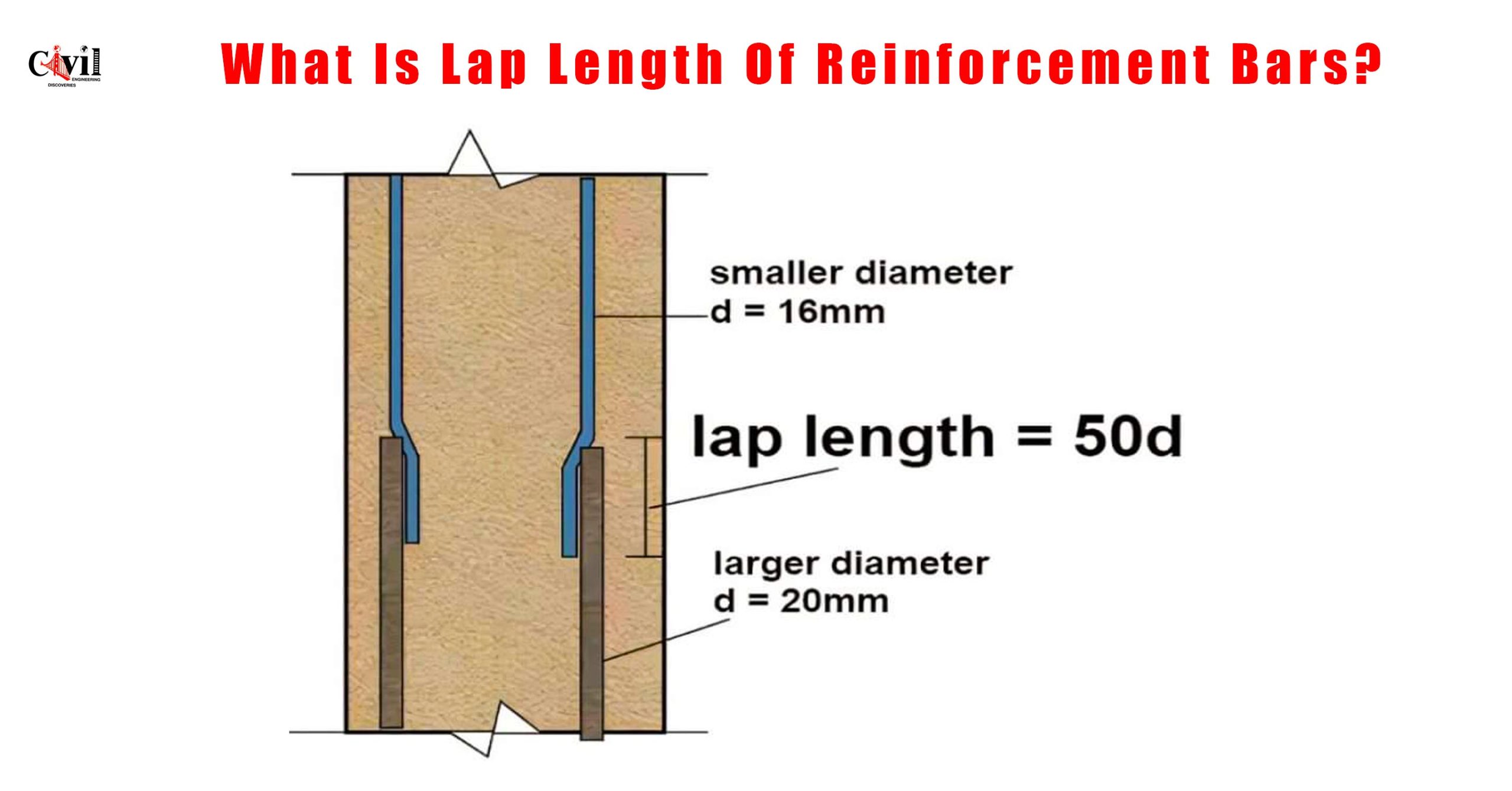

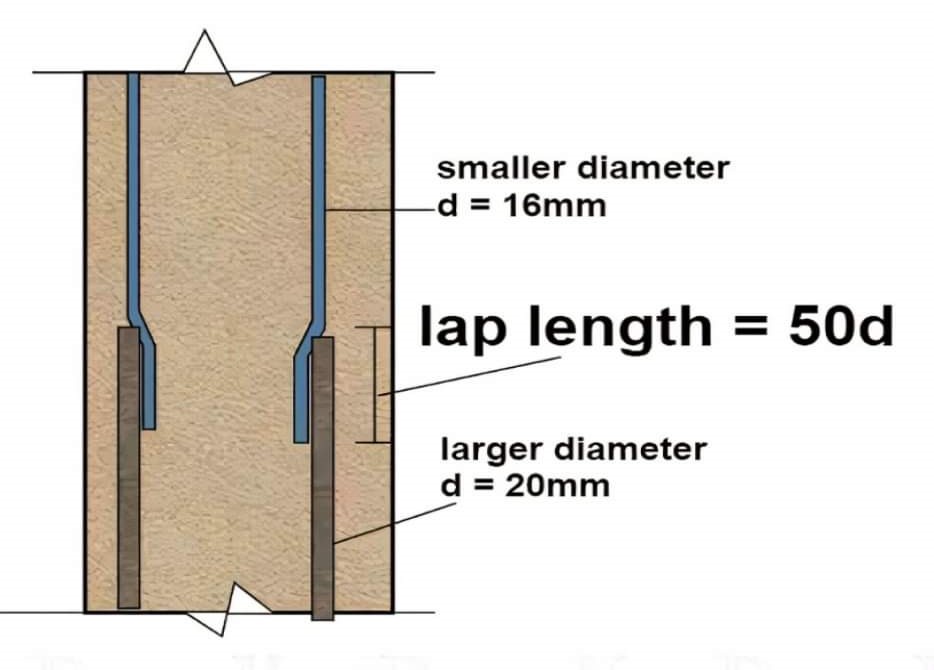

For tension members, the lap length is usually calculated using a simple formula:

Lap Length = 50D

Where:

- D is the diameter of the reinforcement bar.

For example, if the diameter of the rebar is 20 mm, the lap length would be:

50 × 20 = 1000 mm or 1 meter.

In compression members, the lap length is reduced to 40D.

Factors Affecting Lap Length

Several factors influence the required lap length in reinforcement bars:

- Type of Steel: The strength and ductility of the steel rebar can affect the lap length. Higher-grade steel may require longer laps.

- Concrete Strength: The grade of concrete also influences the lap length. Higher-grade concrete may allow for shorter laps.

- Position of Rebars: Whether the rebars are in a tension or compression zone will also affect the lap length. Tension zones require longer laps.

- Bar Diameter: Larger-diameter bars typically require longer lap lengths to maintain structural integrity.

Code Recommendations for Lap Length

In most regions, building codes dictate specific lap length requirements. For example, the Indian Standard (IS 456:2000) recommends a lap length of 50D for tension members and 40D for compression members. It is important to consult local codes and standards when determining the correct lap length for a project.

Best Practices for Lap Length in Rebars

To ensure safety and structural stability, follow these best practices when working with lap lengths:

- Avoid Lapping at Points of Maximum Stress: Laps should not be placed where the structure is experiencing maximum tensile or compressive forces.

- Staggered Laps: Staggering the laps of adjacent bars improves the overall strength of the structure and minimizes weak points.

- Overlap Reinforcement Carefully: Proper care should be taken to align and overlap the reinforcement bars as required, ensuring that the bond is strong.

Click Here To See The Importance of a Drainage Swale in Protecting Your Home