Creating a precise bar bending schedule (BBS) for a two-way slab is essential in construction projects. This step-by-step guide will break down the process clearly and efficiently. Follow these simple steps to streamline your work.

1. Understanding the Requirements of the Two-Way Slab

A two-way slab distributes loads in both horizontal directions. Before preparing the BBS, ensure you have the following details:

- Slab dimensions

- Reinforcement bar details

- Spacing of reinforcement

- Concrete cover thickness

2. Divide the Two-Way Slab into Regions

To prepare a proper schedule, divide the slab into zones. These include:

- Main Bars: Run in both directions, typically bottom reinforcement.

- Distribution Bars: Perpendicular to the main bars, often at the top layer.

3. Identify and List Bar Details

Make a list of bar properties, such as:

- Bar diameter (e.g., 8mm, 10mm, 12mm)

- Bar length based on span dimensions

- Quantity of bars

- Bending shapes and hooks

Ensure all dimensions comply with the structural drawing.

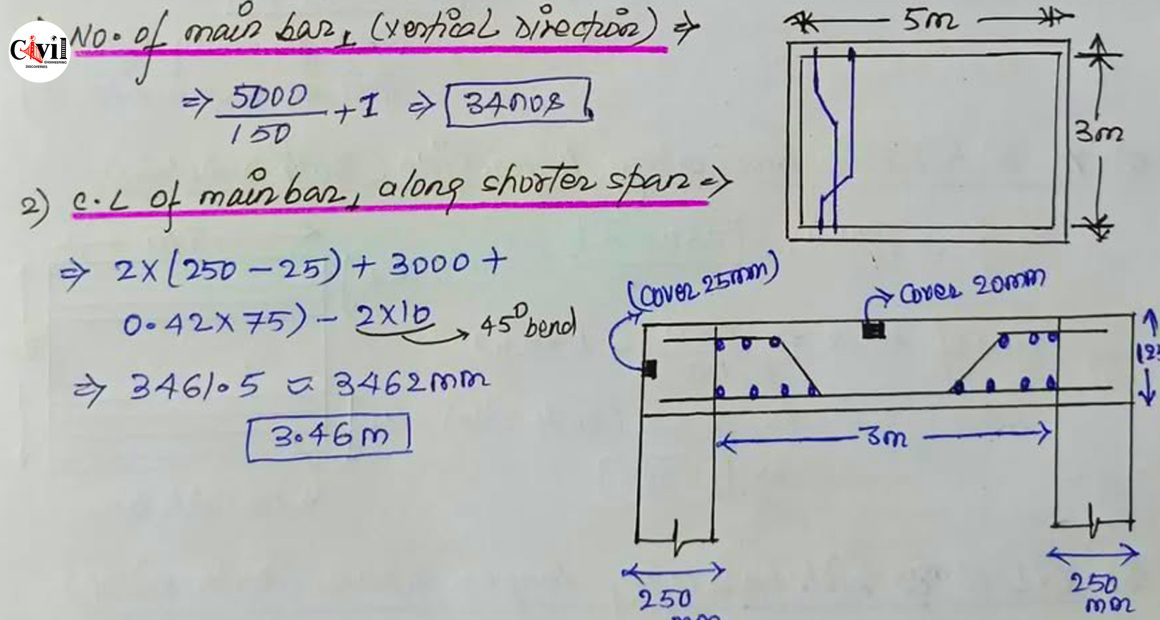

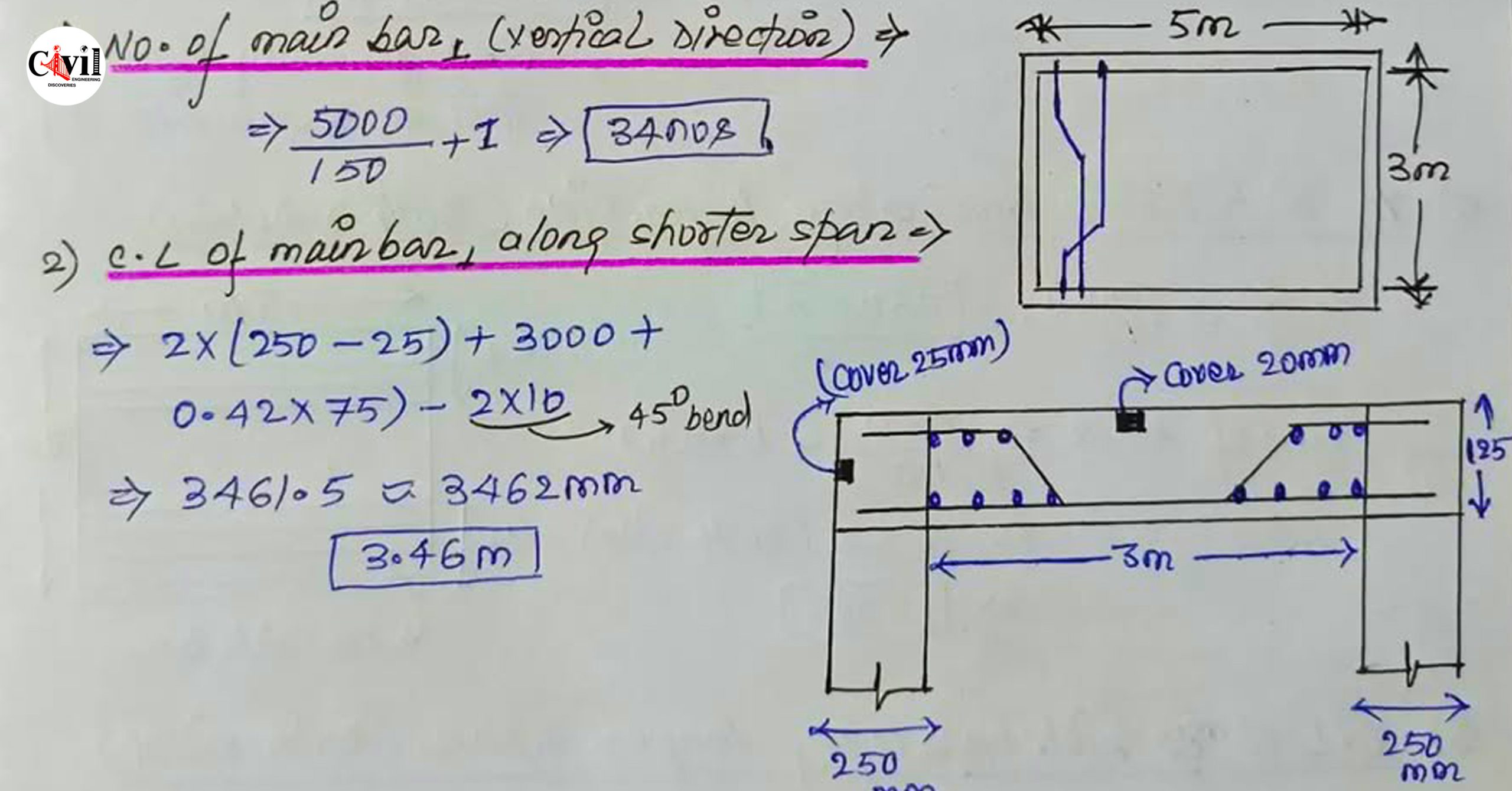

4. Calculate Cutting Length for Bars

To determine the cutting length:

- Start with the clear span length of the slab.

- Add the required development length on both sides.

- Include the bends or hooks as per the standard bar bending rules.

5. Prepare the Bar Bending Schedule Table

Structure the BBS in a clear format with the following columns:

- Bar Mark: Unique identification for each bar.

- Bar Diameter: Thickness of reinforcement bars.

- Bar Shape: Straight, bent, or hook-shaped.

- Length of Bars: Total cutting length.

- Number of Bars: Quantity needed for the slab.

- Total Length: Length per bar × number of bars.

Click Here To See Volume Of Cement, Sand, Aggregate, And Water In Concrete