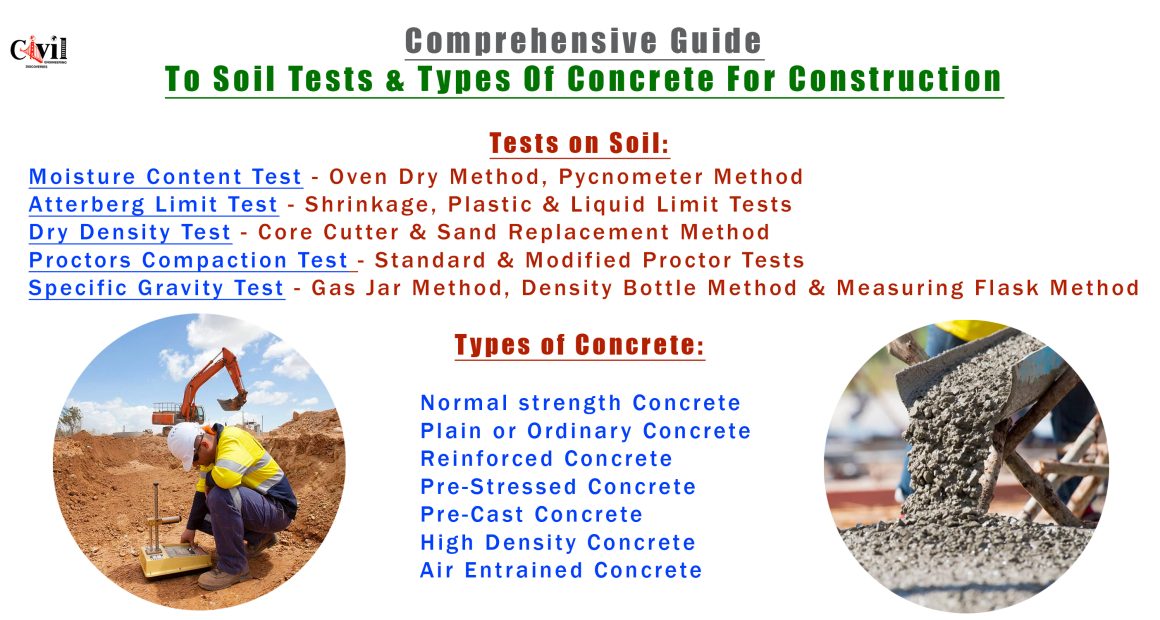

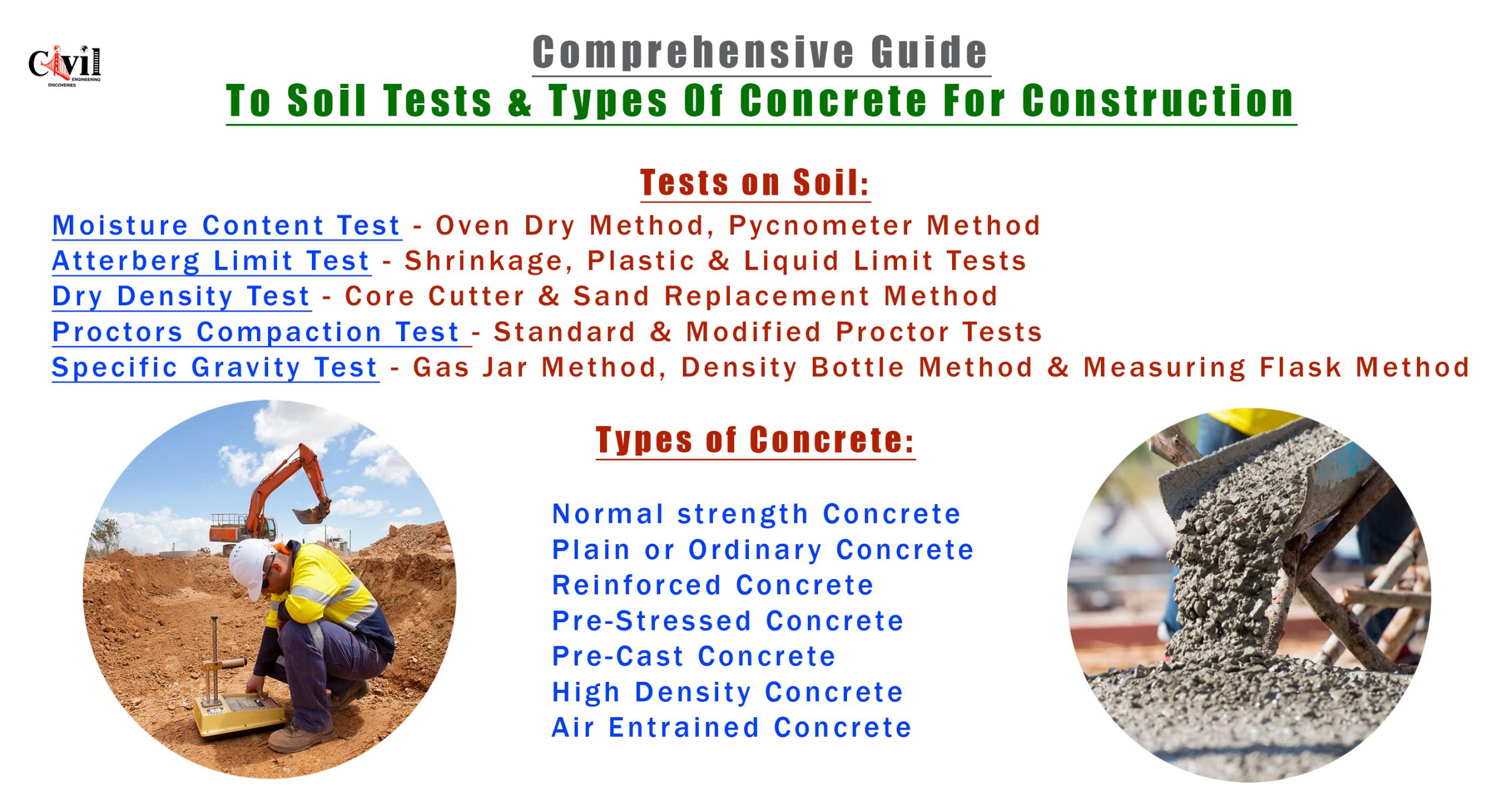

Introduction

In the field of construction, both soil and concrete play a pivotal role in ensuring the stability, durability, and success of any project. Before commencing any construction work, it is essential to conduct thorough soil testing to understand the site conditions and determine its suitability for the intended structure. Equally important is the selection of the appropriate type of concrete to ensure long-lasting performance. This article delves deep into the essential tests conducted on soil and provides an in-depth overview of various types of concrete used in construction.

1. Moisture Content Test

Determining the moisture content of soil is crucial for assessing its stability and strength. High moisture levels can weaken the soil, affecting the foundation’s integrity.

Methods:

- Oven Dry Method: Involves drying soil samples in an oven and measuring the weight difference.

- Pycnometer Method: Utilizes a pycnometer to determine the moisture content by measuring soil sample density.

2. Atterberg Limit Test

This test assesses the plasticity characteristics of fine-grained soil, which helps in understanding its behavior under different moisture conditions.

Types of Atterberg Limit Tests:

- Shrinkage Limit: Determines the moisture content at which the soil volume stops decreasing.

- Plastic Limit: The moisture content at which soil begins to exhibit plastic behavior.

- Liquid Limit: The moisture content at which the soil changes from a plastic state to a liquid state.

3. Dry Density Test

The dry density of soil is a critical factor that affects the compaction and load-bearing capacity.

Methods:

- Core Cutter Method: Involves extracting a cylindrical core of soil and measuring its weight and volume.

- Sand Replacement Method: Measures the volume of soil removed and replaces it with sand to determine the density.

4. Proctor Compaction Test

This test determines the optimal moisture content at which the soil achieves its maximum dry density.

Types:

- Standard Proctor Test: Utilizes a fixed amount of compaction effort.

- Modified Proctor Test: Involves a higher compaction effort for greater accuracy.

5. Specific Gravity Test

Specific gravity is the ratio of soil solids’ weight to an equal volume of water. It helps identify the soil type and its potential suitability for construction.

Methods:

- Gas Jar Method: Measures the specific gravity using a gas jar.

- Density Bottle Method: Utilizes a density bottle for accurate measurements.

- Measuring Flask Method: Provides a quick estimation of specific gravity.

Concrete is a composite material widely used for building foundations, pavements, bridges, and other structures. Selecting the appropriate type of concrete is essential to meet the specific requirements of a project.

1. Normal Strength Concrete

This is the most commonly used type of concrete, with a typical mix ratio of 1:2:4 (cement: sand: aggregates). It has moderate compressive strength and is suitable for general construction purposes.

2. Plain or Ordinary Concrete

Plain concrete does not contain reinforcement and is primarily used for pavements and small-scale construction. It is best suited for applications where tensile strength is not a critical factor.

3. Reinforced Concrete (RCC)

Reinforced concrete contains embedded steel bars or meshes to improve its tensile strength. It is widely used for constructing beams, columns, slabs, and other structural elements.

4. Pre-Stressed Concrete

This type of concrete is subjected to pre-tensioning or post-tensioning to enhance its strength and durability. Pre-stressed concrete is commonly used in bridges, flyovers, and large-span structures.

5. Pre-Cast Concrete

Pre-cast concrete components are manufactured off-site and transported to the construction site for assembly. This method ensures consistent quality and reduces construction time.

6. High-Density Concrete

High-density concrete is produced using heavy aggregates such as barite or magnetite. It provides excellent radiation shielding and is often used in nuclear power plants and medical facilities.

7. Air-Entrained Concrete

Air-entrained concrete contains tiny air bubbles that improve its resistance to freeze-thaw cycles and enhance durability. It is commonly used in cold climates and pavements.

Click Here To See Methods To Improve The Bearing Capacity Of Soil