Civil engineers, site engineers, or supervisors must be familiar with Thumb Rules for Civil Engineering. These rules assist in making quick and efficient decisions on-site. They help estimate materials, dimensions, and construction parameters with simple mathematical formulas. However, these rules provide approximations and not exact results.

Thumb Rules for Concrete Work

- 28 days strength is the characteristic strength of concrete – Determines the concrete strength after 28 days of curing.

- One-fourth of the concrete section should have steel reinforcement – Estimates steel reinforcement in slabs and foundations.

- Excavation depth should be 1.5 times the foundation width – Ensures structural stability.

- The water-cement ratio should be 0.5. This helps maintain durability and strength.

- A single layer of vibrator for every 12 feet – Ensures proper compaction and reduces air bubbles.

- A slump test should be performed before pouring concrete – Checks the consistency of the concrete mix.

- Volume of concrete required = 0.038 m³ /sq. ft. – Used for quick calculations of concrete volume.

Thumb Rules for Slab

- Minimum slab thickness – 125mm.

- Minimum diameter of bars – 8mm.

- Fe 500 Steel should be used in RCC slabs.

- Clear cover for reinforcement – 15-20mm.

- Maximum bar diameter – 1/8th of slab thickness.

- Steel required in RCC slab – 1% of total concrete volume.

- M15 grade concrete or higher should be used.

- Reinforcement spacing – Not less than 150mm c/c.

Thumb Rules for Beam

- Steel required in RCC beam – 2% of total concrete volume.

- Minimum clear cover – 40mm.

- Minimum reinforcement – 4 bars: 2 bars of 12mm at the top and 2 bars of 10mm at the bottom.

- M20 grade concrete should be used in RCC beam construction.

- Spacing of reinforcement bars – Not less than 150mm c/c.

Thumb Rules for Column

- Steel reinforcement spacing – Not more than 300mm.

- Minimum clear cover – 40mm (25mm for columns < 200mm).

- M20 grade concrete is recommended for columns.

- Fe 500 steel is recommended for reinforcement.

- Minimum bar diameter – 12mm, with at least 4 bars per column.

- Maximum reinforcement bar diameter – 50mm.

- Overlapping distance – 24 times the smallest bar diameter.

- Maximum stirrup spacing – 16D, B, or 300mm (whichever is lesser).

- Steel required in the column – 2.5% of total concrete volume.

- Minimum steel requirement in column – 0.8% of gross concrete area.

- Maximum steel requirement in column – 6% of gross concrete area.

- Minimum column size – 9” x 9”.

- G+1 structures – Use 9” x 12” (225mm x 300mm) RCC columns.

- Maximum column spacing – Not more than 4 meters for a 9” x 9” column.

Thumb Rules for Foundation

- Steel required in RCC footing – 0.8% of total concrete volume.

- Clear cover for footing reinforcement – 50mm.

- Minimum bar diameter – 10mm.

- M20 grade concrete or higher should be used.

- Foundation dimensions – Length, width, and depth should not be less than 1 meter.

- Minimum footing thickness – 40cm.

- Pile foundation is required if the soil bearing capacity is < 24 kN/m³.

Thumb Rules for Building Estimation

- Steel required for residential buildings – 4.5 – 4.75 kg/sq. ft.

- Steel required for commercial buildings – 5.0 – 5.5 kg/sq. ft.

- BN Datta recommendations for accurate results.

Steel Quantity in Structural Members:

- Slab – 1% of concrete volume.

- Beam – 2% of concrete volume.

- Column – 2.5% of concrete volume.

- Footings – 0.8% of concrete volume.

Thumb Rule for Shuttering Work

- Shuttering costs – 15-18% of the total construction cost.

- Shuttering quantity – 6 times concrete quantity or 2.4 times plinth area.

- Example: For 0.5m³ of concrete, shuttering area = 0.5 x 6 = 3m².

Components of Shuttering:

- Ply Sheets – Required quantity = 0.22 x shuttering area.

- Battens Quantity – 19.82 x No. of Ply Sheets.

- Nails & Binding Wire – 75g per 1m² of shuttering.

- Shuttering Oil – 1 liter for every 15m².

Thumb Rules for Brickwork

Brickwork Cement Requirement:

| Brickwork Type | Cement (m³) | Cement (Bags) |

|---|---|---|

| 230mm Brickwork | 0.876 | 25.4 |

| 115mm Brickwork | 0.218 | 6.32 |

Thumb Rules for Cement Masonry Quantity

Masonry Mix Ratios & Cement Consumption:

| Masonry Type | Cement (Bags/m²) | Cement (Kg/m²) |

| 200mm (1:6) | 0.124 | 6.2 |

| 150mm (1:6) | 0.093 | 4.65 |

| 200mm (1:4) | 0.206 | 10.3 |

| 150mm (1:4) | 0.144 | 7.2 |

| 100mm (1:4) | 0.103 | 5.15 |

Thumb Rule for Plastering Work

| Plastering Type | Cement (Bags/m²) | Cement (Kg/m²) |

| Rough Plastering | 0.09 | 4.5 |

| Internal Wall Plastering | 0.09 | 4.5 |

| External Wall Plastering | 0.175 | 8.75 |

| Stucco Plastering | 0.175 | 8.75 |

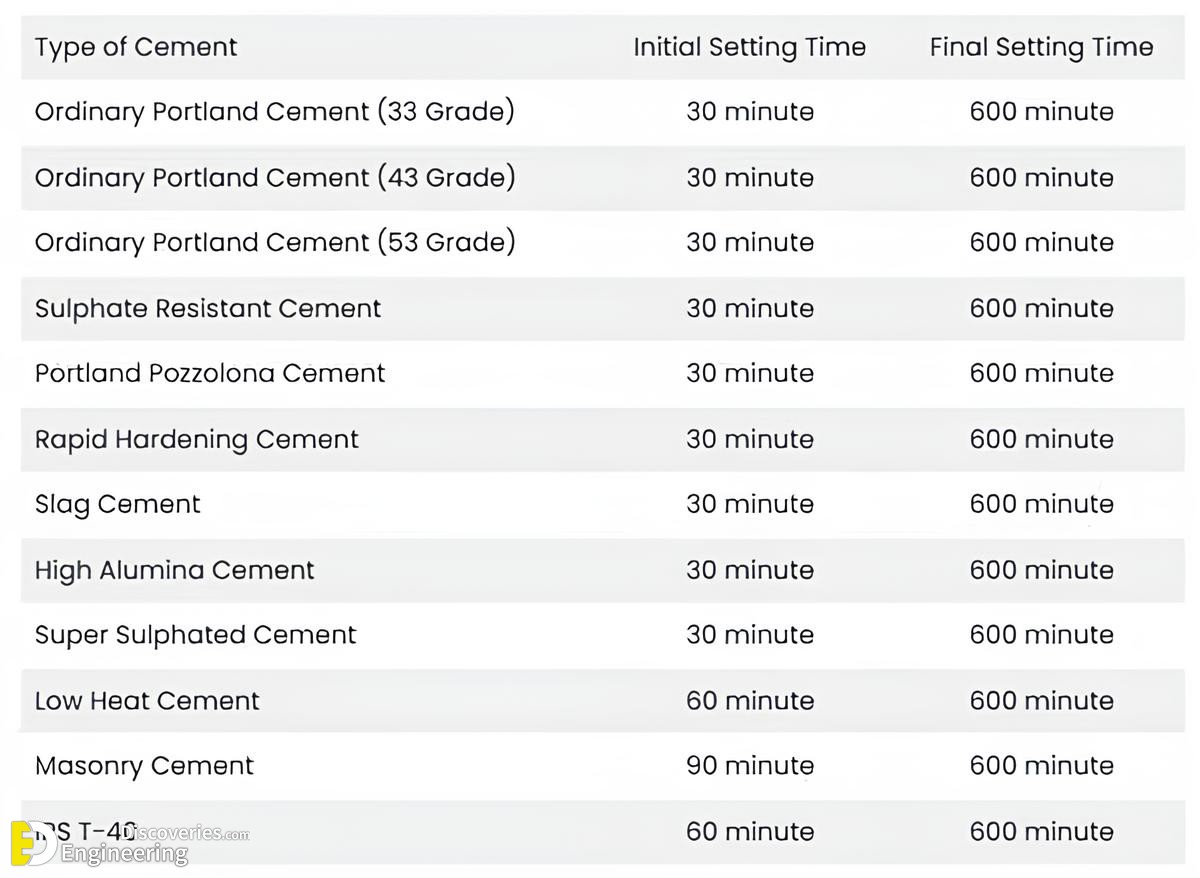

Cement Setting Time

- Initial Setting Time – 30 minutes (measured with Vicat Apparatus).

- Final Setting Time – Depends on cement type and grade.

Click Here To See Circular Vs Square: Which Column Is Preferred For House Construction