U-Type concrete stairs are a popular architectural element for their strength, durability, and aesthetic appeal. They provide a seamless transition between levels while ensuring safety and stability. U-type concrete stairs detail. U-shaped stairs are essentially two parallel flights of straight stairs joined by a landing that creates a 180-degree turn in the walk line.

Proper reinforcement is crucial to enhance their load-bearing capacity and longevity. This article delves into the detailed construction and reinforcement of U-type concrete stairs.

Structural Components of U-Type Concrete Stairs

U-type stairs consist of several key structural elements that ensure stability and durability. These include:

- Treads and Risers – The horizontal and vertical components that form the stepping surface.

- Stringers – Side supports that carry the load of the stairs.

- Landings – Intermediate platforms for safety and comfort.

- Reinforcement Bars (Rebars) – Steel bars embedded in concrete to resist tensile forces.

- Concrete Slab – A monolithic structure that integrates all elements for strength and stability.

Reinforcement Details for U-Type Concrete Stairs

Reinforcement plays a crucial role in ensuring the durability and strength of U-type stairs. The key aspects of reinforcement include:

1. Main Reinforcement Bars

The primary reinforcement bars, typically high-yield steel, are placed along the tension zone of the stairs. They prevent cracking and enhance the structural integrity.

- Bottom Reinforcement – Provided along the bottom face of the stair slab to resist tensile forces.

- Top Reinforcement – Placed at the top surface where compression forces act.

- Side Reinforcement – Ensures stability along the stringers.

2. Distribution Bars

Secondary reinforcement bars distribute the load evenly and prevent localized cracking. These bars run perpendicular to the main reinforcement.

- Spacing – Typically maintained between 100mm to 200mm, depending on design requirements.

- Diameter – Usually ranges from 8mm to 12mm based on structural calculations.

3. Additional Stirrups and Hooks

To enhance the load-carrying capacity, additional stirrups and hooks are incorporated:

- Stirrups – Placed at the supports to resist shear forces.

- Hooks – Provide anchorage and improve bond strength between steel and concrete.

Design Considerations for U-Type Concrete Stairs

A well-designed U-type stair must adhere to structural and aesthetic requirements. Key design parameters include:

1. Load-Bearing Capacity

The stair design should accommodate both dead loads (self-weight) and live loads (people and furniture). The standard load considerations include:

- Residential Buildings – 2 kN/m² to 3 kN/m²

- Commercial Buildings – 4 kN/m² to 5 kN/m²

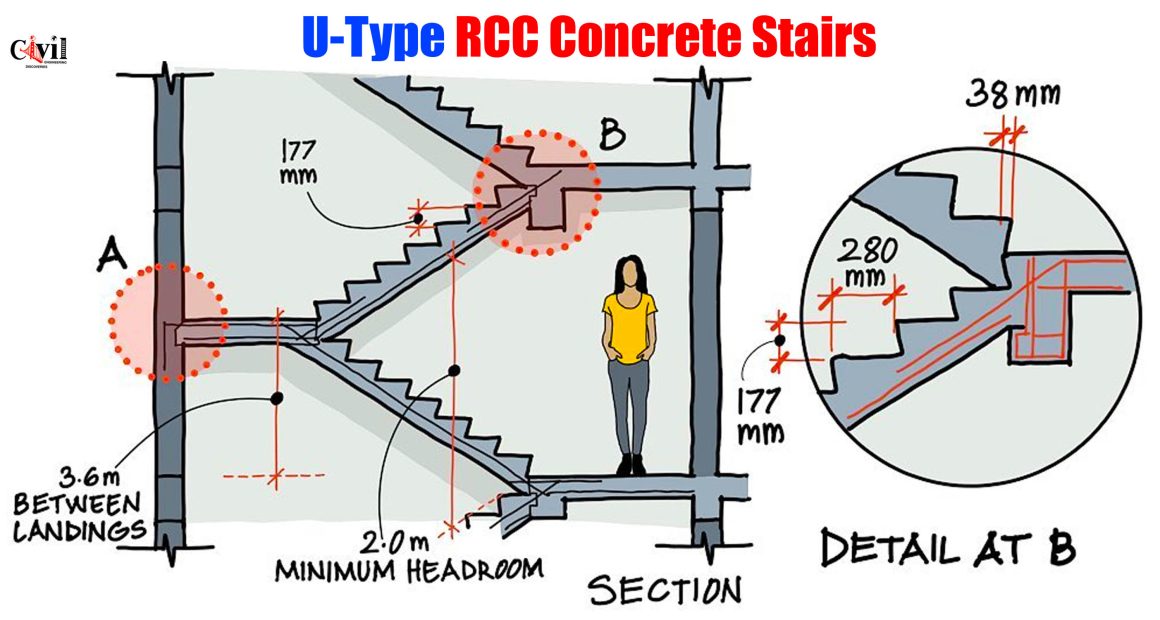

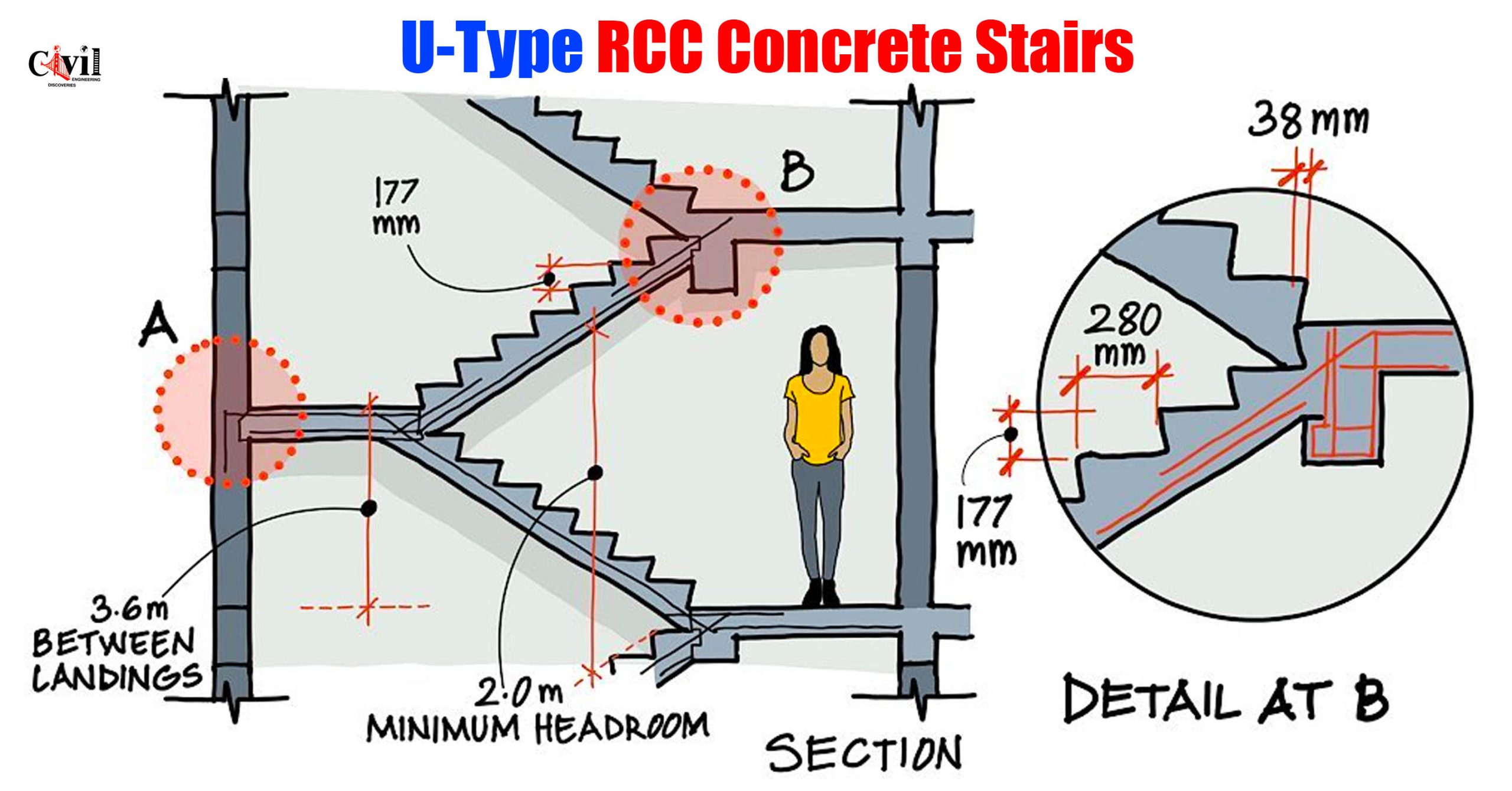

2. Stair Dimensions

The dimensions should comply with building codes for safety and comfort:

- Tread Width – 250mm to 300mm for proper foot placement.

- Riser Height – 150mm to 180mm for ease of climbing.

- Landing Length – Minimum 900mm for resting space.

- Staircase Width – At least 1000mm for residential and 1200mm for commercial buildings.

3. Concrete Mix Proportion

The quality of concrete directly impacts the durability and strength of the stairs. Recommended mix proportions include:

- M20 Grade Concrete – 1:1.5:3 (Cement: Sand: Aggregate) for residential use.

- M25 Grade Concrete – 1:1:2 for heavy-load structures.

Water-cement ratio should be maintained at 0.45 to 0.5 for workability and strength balance.

Construction Process of U-Type Concrete Stairs

1. Formwork Preparation

Formwork provides the required shape and support during concrete pouring. It should be rigid, leak-proof, and properly aligned.

- Plywood or Steel Formwork – Used for a smooth finish.

- Side Supports and Props – To hold the formwork firmly in place.

2. Placement of Reinforcement

The reinforcement bars are tied in place as per the structural drawing. Proper cover (25mm to 40mm) is provided to prevent corrosion.

3. Concrete Pouring and Curing

Concrete is poured in layers and vibrated to remove air pockets. Proper curing for 14 to 28 days enhances durability and prevents cracks.