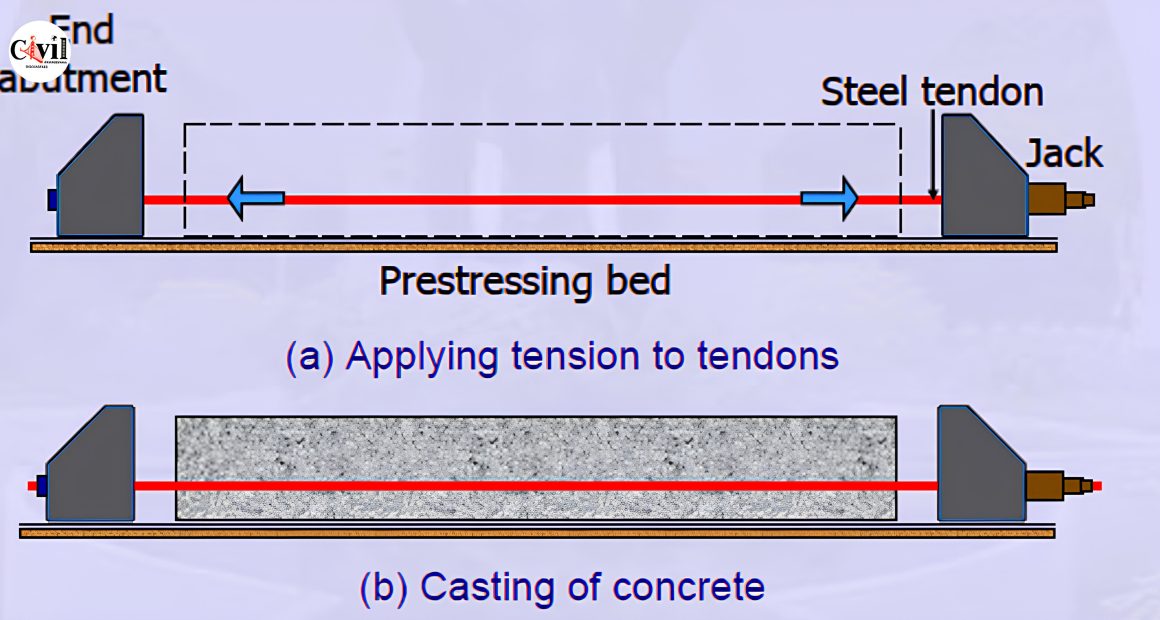

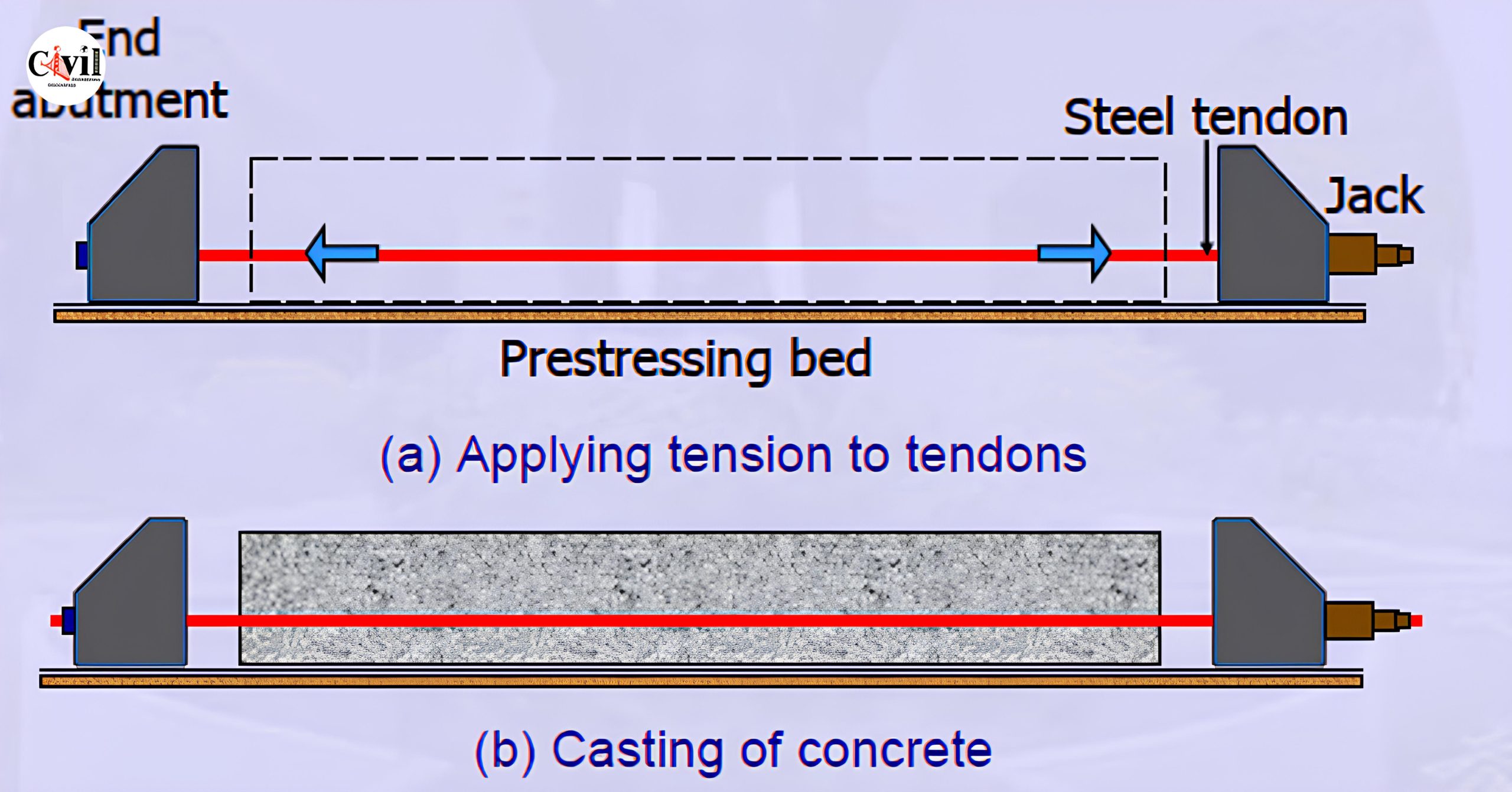

Prestressed concrete is a type of concrete in which an appropriate amount and distribution of internal stress are supplied to counteract the stresses caused by external loads to the desired degree. In the concrete section, high-strength steel wire or alloys (known as ‘tendons’) are provided so they generate the initial compression. Because an initial load is applied to the structure before its use, prestressed concrete differs from traditional RCC structures.

Prestressing is a technique for preventing cracks, increasing the part’s strength, and reducing deflection. Prestressing is a technique for achieving a lower depth, longer span, and improved strength in a structure.

Prestressed concrete is widely used in the construction of buildings and bridges due to its durability, reliability, and strength. Here are some of the advantages and disadvantages of prestressed concrete

Advantages:

- Longer span length: This increases untroubled floor space and parking facilities.

- Thinner slabs: Important for high-rise buildings as they can construct more slabs than traditional thicker slabs with the same amount of cost.

- Fewer joints: As the span length is larger, fewer joints are needed than in traditional RC structures. This also reduces maintenance costs as joints are the major locus of weakness in a concrete building.

- Untracked under service loading conditions: This reduces steel corrosion and achieves long-term durability.

- Higher moment of inertia: Fewer deformations and high shear capacity are achieved with a lower section size.

- Requires fewer construction materials: This leads to cost savings.

- Better finishing of placed concrete: It resists stresses that are higher than normal RCC structures and is free from cracks.

- Rapid construction with better quality control: Less maintenance is required.

- Suitable for repetitive construction: In this type of concrete, multiple uses of formwork are possible, reducing the amount of formwork.

Disadvantages:

- Requires high-strength concrete and high-tensile-strength steel wires: This can increase the cost.

- Requires additional special equipment: Such as jacks, anchorage, etc.

- Requires skilled technology and highly skilled workers: This can also increase the cost.

- Construction cost is higher than RCC structures: This is due to the higher cost of high-strength materials.

While prestressed concrete has many advantages, it also has some disadvantages that need to be considered. The choice between using prestressed concrete or other types of concrete depends on various factors such as the specific requirements of the project, cost considerations, and the availability of skilled workers and special equipment.

Click Here To See Which Column Is stronger? Circular vs Rectangular vs Square!!