Beam-column connections are among the most critical joints in transferring loads between beams and columns, providing stability and strength to any structure. The backbone of any building can prove quite tricky to get right in terms of design and construction. Let us now take a look at the basic steps, classification, and best practices of beam-column connections that can be operated to maintain joint integrity.

Why Beam-Column Connections Matter:

Load Transfer: These connections ensure loads from beams are safely transferred into columns and eventually to the foundation.

Structural Integrity: Connections must be proper to prevent excessive movement, bending, or rotation in the structure for stability and durability.

Seismic Resistance: Well-designed beam-column connections can prevent collapse in the case of seismic events in earthquake-prone areas.

Types of Beam-Column Connections:

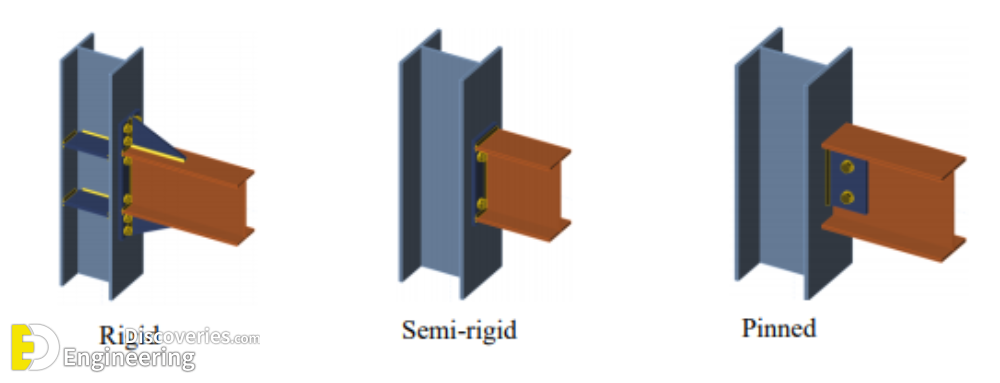

Rigid (Moment) Connections: Detailed to resist the rotation and, hence, to preserve the fixed angle between the beam and column. These are typically adopted in buildings requiring more rigidity, such as high-rise buildings or structures in seismic zones.

Supported (pinned) connections: They allow some rotation but resist vertical forces. They are the simplest and cheapest to construct. They are generally used in buildings where some flexibility is tolerable.

Semi-rigid connections: Those that permit small rotations while resisting vertical and horizontal loads. The connections balance the cost with rigidity and are usually found in applications where some flexibility in the structure is desired.

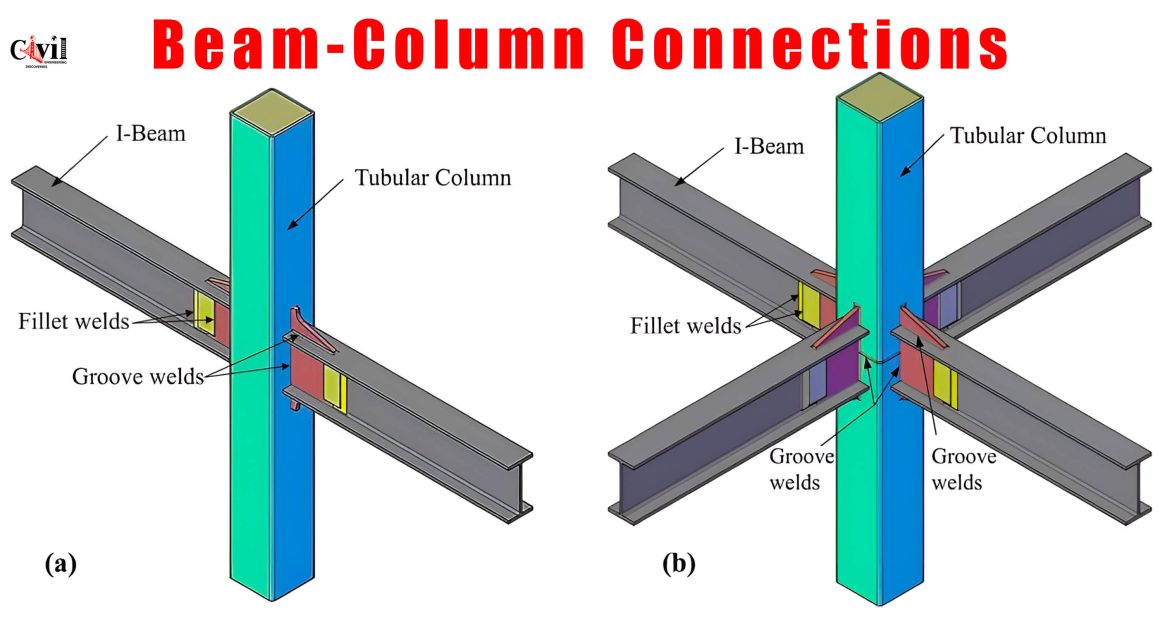

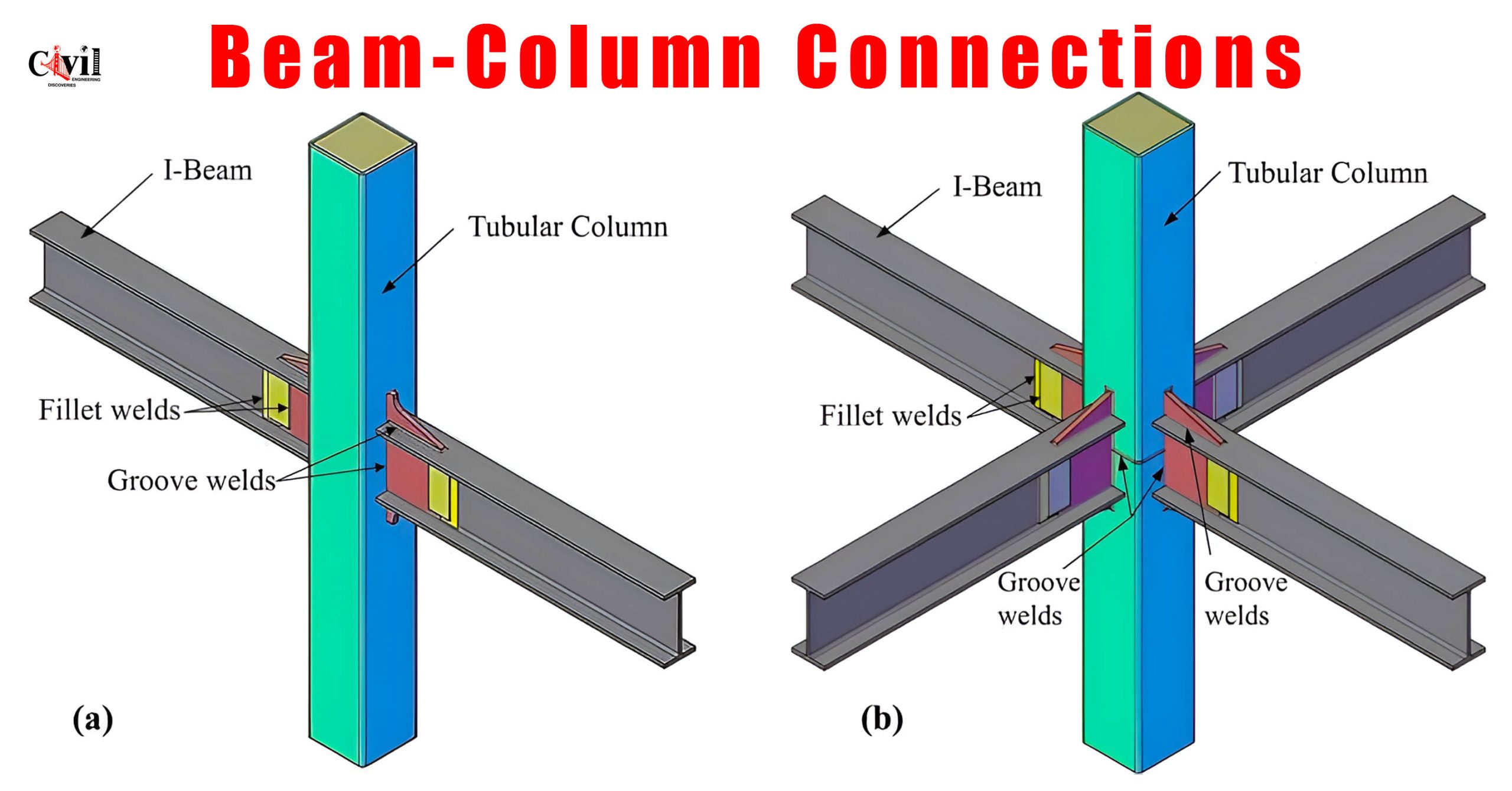

Welded vs. Bolted Connections: The connections may be welded to provide greater rigidity or bolted for ease of assembly and adjustability. Both have their pluses depending on the project design and load requirements.

Challenges in Beam-Column Connection Design:

Load Distribution: All loads must be distributed evenly over the connection so as not to overstress bolts or welds.

Seismic Considerations: Connections must be capable of absorbing energy and permitting controlled movement during earthquakes. Special reinforcement is usually required.

Alignment Issues: Misalignment of beams or columns can compromise joint integrity, leading to stress concentrations.

Corrosion Protection: In specific cases of exterior or exposed connections, corrosion can also weaken joints over time. Proper coatings or materials must be used.

Thermal Effects: Where temperatures change significantly, expansion and contraction due to heat can put stress on connections.

Best Practices for Beam-Column Connections

Choose the Right Connection Type. The structural needs, budget, and location will determine the use of rigid, simple, or semi-rigid connections.

Use High-Quality Fasteners: The bolts or welding materials used must be able to match or exceed the beams’ and columns’ strength for a reliable connection.

Ensure Proper Alignment: Proper alignment during construction prevents stress concentrations and ensures load distribution is even.

Consider reinforcement for seismic loads: Add reinforcement in connections in earthquake areas, such as additional bracing or energy-absorbing materials.

Regular Inspection: Connections should be inspected at regular intervals, especially in corrosive or high-stress environments, to detect any incipient problems.

Subscribe

Login

0 Comments

Newest