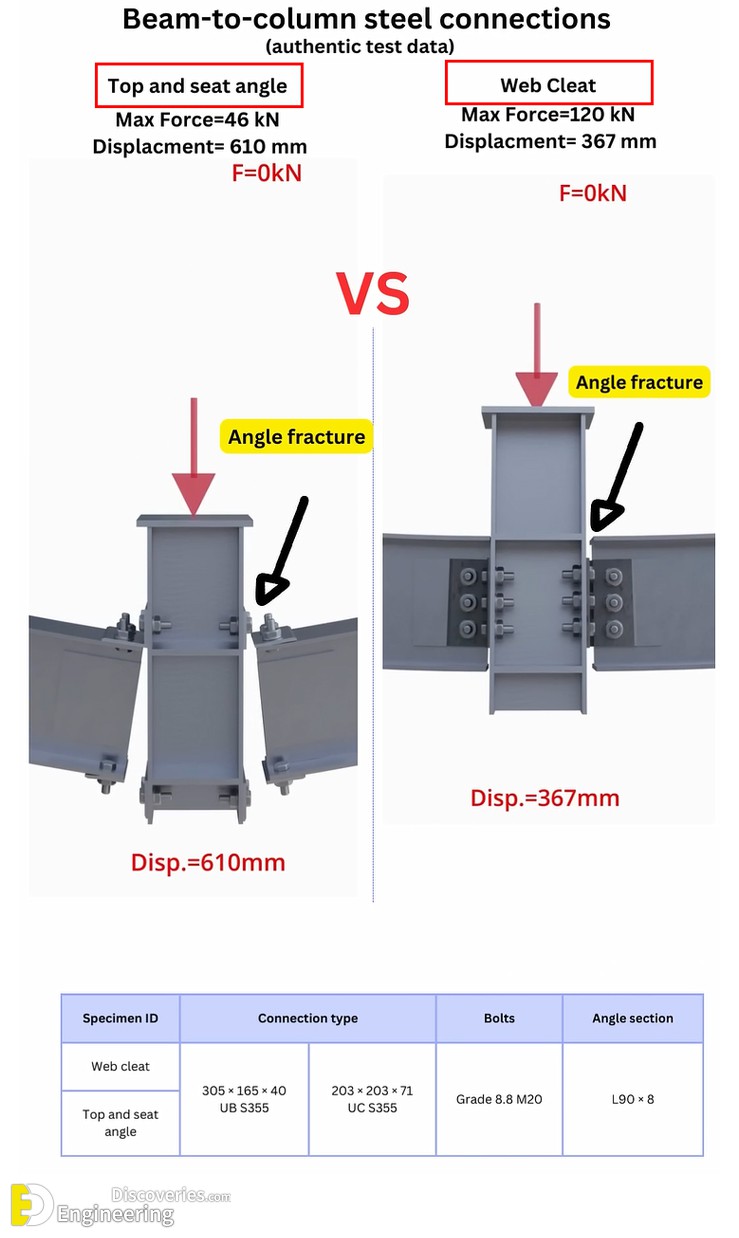

In the realm of structural engineering, the choice of the right beam-to-column connection is crucial for the safety, stability, and durability of steel structures. Among the most popular connection types, Top and Seat Angle and Web Cleat configurations have stood the test of time. However, when faced with the challenge of choosing the stronger and more reliable connection, a closer examination of authentic test data reveals the definitive answer.

Understanding Beam-to-Column Connections

Beam-to-column connections play a critical role in transferring loads between horizontal and vertical members in steel frameworks. They ensure that forces such as bending moments, shear forces, and axial loads are safely distributed throughout the structure, preventing catastrophic failures.

Top and Seat Angle Connection: Overview and Performance

The Top and Seat Angle connection is a traditional method where angles are bolted or welded to the top and bottom of the beam. This design offers simplicity and ease of assembly.

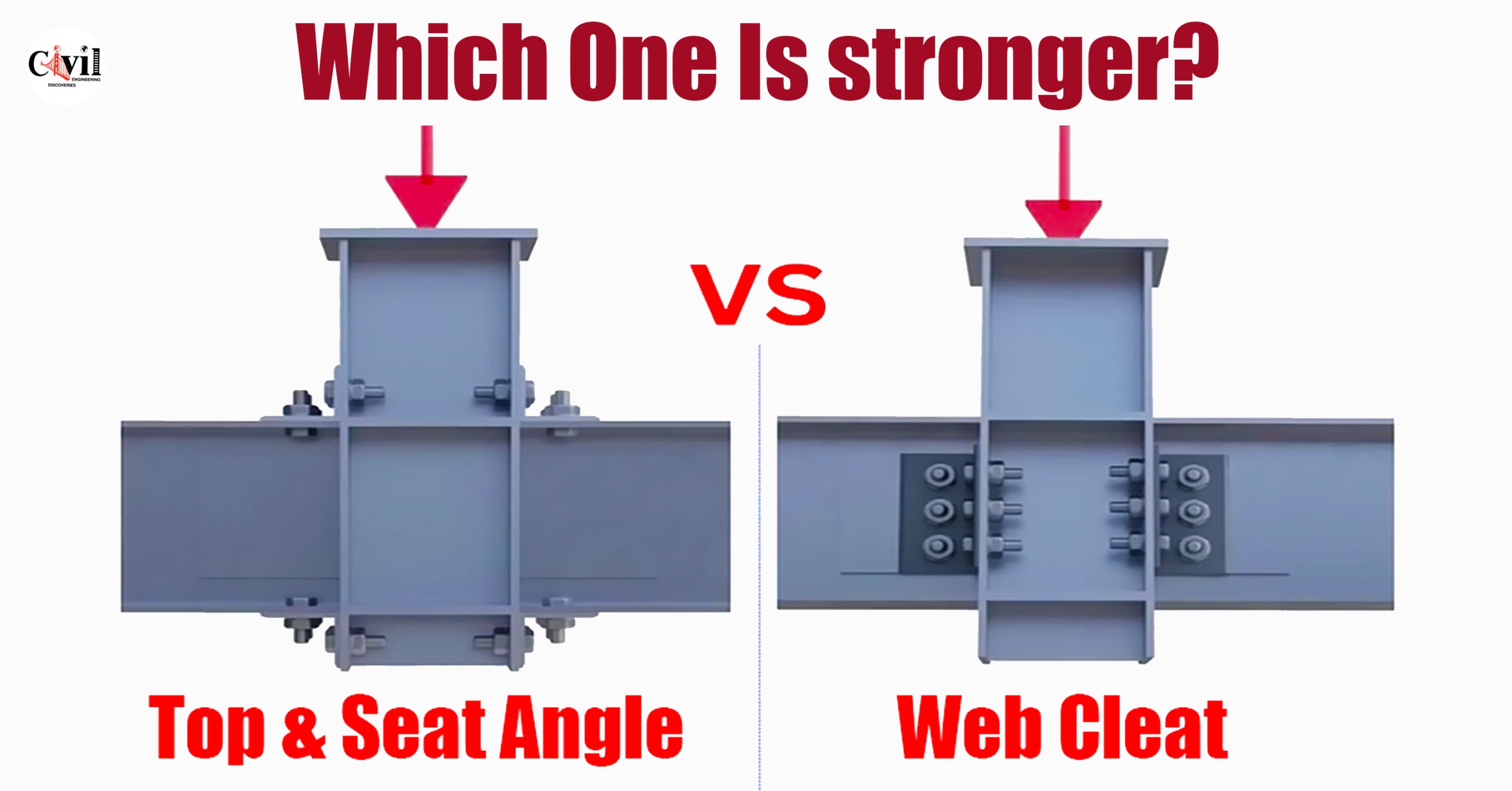

Max Force Capacity: 46 kN

Displacement at Failure: 610 mm

Failure Mode: Angle fracture

Top and seat angle connections primarily rely on the bearing and friction between the beam and angles. However, the test results reveal a significant limitation: only 46 kN of force was resisted before failure, accompanied by a large displacement of 610 mm. Such a high displacement indicates greater deformation, which can compromise the serviceability and aesthetic integrity of the structure before ultimate failure.

Web Cleat Connection: Overview and Performance

The Web Cleat connection involves bolting a pair of angles (cleats) to the web of the beam and the column flange. This design ensures a more direct transfer of forces.

Max Force Capacity: 120 kN

Displacement at Failure: 367 mm

Failure Mode: Angle fracture

When compared to the top and seat angle connection, the web cleat setup demonstrated over 2.5 times higher strength, withstanding 120 kN of force before failure. Moreover, the smaller displacement of 367 mm points to a stiffer and more resilient behavior under load. The reduced deformation translates into improved structural performance and occupant comfort in buildings.

Material and Specification Details

Both connections used Grade S355 steel, a high-strength structural steel, ensuring material properties were not the differentiating factor. Bolts used were Grade 8.8 M20, known for their high tensile strength, maintaining consistency in connection hardware.

Specifics:

Web Cleat: 305 × 165 × 40 UB S355 section

Top and Seat Angle: 203 × 203 × 71 UC S355 section

Angle Sections: L90 × 8 mm

Comparison Between Web Cleat and Top and Seat Angle Connections

| Feature | Top and Seat Angle | Web Cleat |

|---|---|---|

| Max Force Capacity | 46 kN | 120 kN |

| Displacement at Failure | 610 mm | 367 mm |

| Failure Mode | Angle fracture | Angle fracture |

| Material | S355 | S355 |

| Bolt Grade | 8.8 M20 | 8.8 M20 |

| Angle Section | L90 × 8 | L90 × 8 |

From this comparison, it is unequivocally clear that the Web Cleat connection outperforms the Top and Seat Angle connection in both strength and stiffness.

Why the Web Cleat Connection is Superior

1. Higher Load-Carrying Capacity

Withstanding 120 kN of force compared to the 46 kN for the top and seat angle, web cleats offer significantly better load transfer capability. This makes them ideal for applications where heavy loads and critical structural performance are paramount.

2. Reduced Displacement

The web cleat design results in only 367 mm of displacement, showing greater resistance to deformation. Structures using web cleat connections maintain their integrity and alignment better under service loads, reducing maintenance costs and extending lifespan.

3. Better Load Path and Force Distribution

By connecting directly through the beam web, web cleats provide a more efficient force path. The force is directly transmitted between the beam and the column without relying excessively on friction, as in the top and seat angle method.

4. Enhanced Ductility

Despite being stronger, web cleats still allow for sufficient ductility, as evidenced by the angle fracture failure mode. Ductility is crucial in seismic design, providing warning before failure and absorbing energy during dynamic events.

Applications Best Suited for Web Cleat Connections

Given their superior performance, web cleat connections are highly recommended for:

High-rise buildings requiring robust moment connections.

Industrial structures with heavy machinery loads.

Seismic zones where ductile behavior is essential.

Bridges and large-span structures demand high load capacities.

Limitations and Considerations

While the web cleat connection is stronger, it is important to consider certain practical aspects:

Installation complexity: Slightly higher due to alignment precision required for the cleats.

Cost: Marginally more expensive due to more bolts and labor.

Inspection and maintenance: More bolts imply more elements to inspect.

Nevertheless, these disadvantages are minor when weighed against the structural benefits provided by web cleats.

Concluding Insights: Which Connection Should You Choose?

When the priority is higher strength, better stiffness, and overall structural reliability, Web Cleat connections are the clear winner over Top and Seat Angle connections. The empirical data underlines the significant margin by which web cleats outperform traditional top and seat angle designs.

Web cleats are the future-proof choice for engineers and designers aiming to achieve safe, durable, and high-performing structures.

If you are involved in steel design and aim to build structures that excel in safety, resilience, and longevity, opting for Web Cleat connections is a strategic and sound decision.

Click Here To See Which Column Is stronger? Circular vs Rectangular vs Square!!