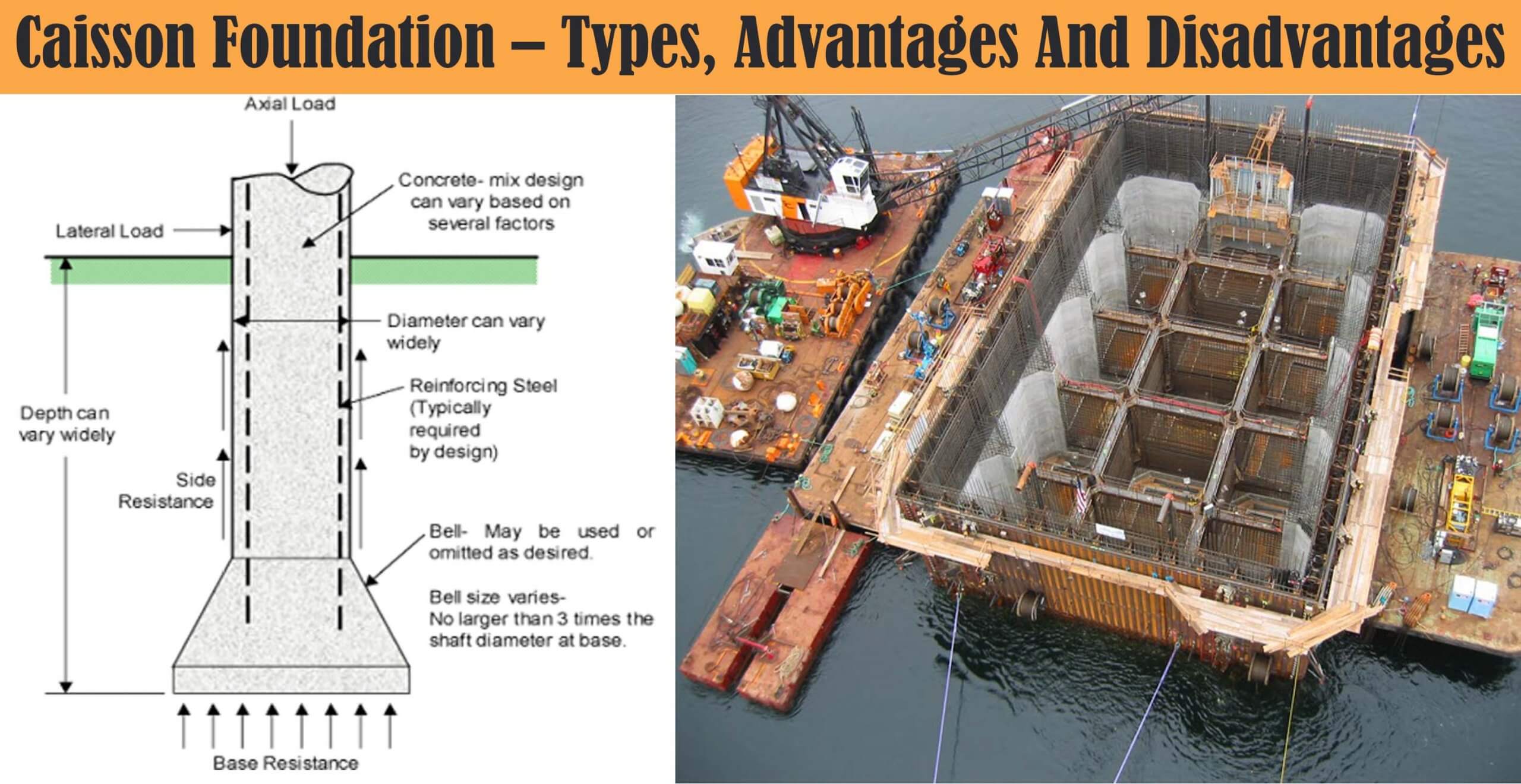

A caisson is a water-tight box-like structure or a chamber, made of wood, steel, or concrete, usually sunk by excavating within it, for the purpose of gaining access to the bed of a stream and placing the foundations at a prescribed depth and which subsequently forms part of the foundation itself. Caissons are adopted when the depth of water is great and the foundations are to be laid underwater. Caissons are generally built on the shore and launched into the river floated to the site and sunk at the proper position.

Functions of Caisson Foundation

1- The foundation system of and the soils beneath the building prevent the complex from moving vertically. When a load is placed on soil, most soils settle. This creates a problem when the building settles but the utilities do not.

2- Even more critical than a settlement is a differential settlement. This occurs when parts of your building settle at different rates, resulting in cracks, some of which may affect the structural integrity of the building.

3- Conversely, in some rare instances soils may swell, pushing your building upwards and resulting in similar problems. Therefore, the foundation system must work in tandem with the soils to support the building.

Type Of Caissons

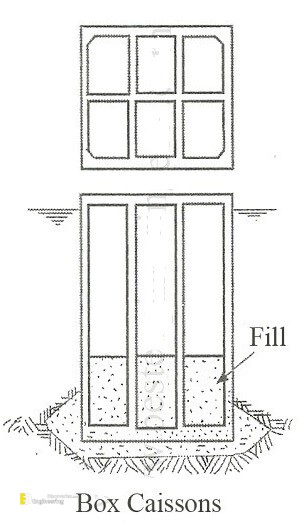

1- Box Caissons

The caisson in the form of an airtight vessel without top, floated to the site and sunk to rest on a firm base, is called box caisson. This type of caisson is made of timber, steel or reinforced concrete.

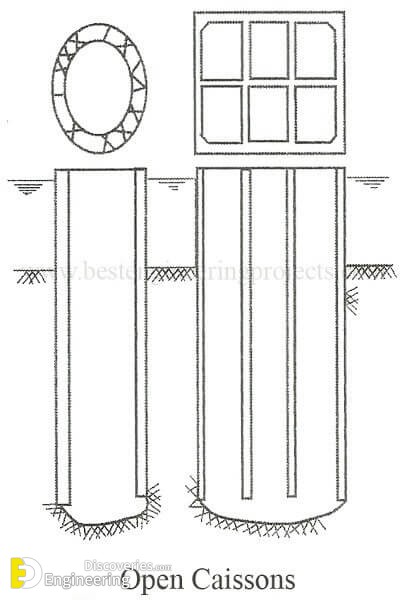

2- Open Caisson

The caisson which is without its top and bottom are called open caisson. This type of caisson is like a well with vertical sides only. It may be square, rectangular, oval or of any other suitable shape. Open caissons are usually made of RCC or of steel plates, riveted or welded together.

3- Pneumatic Caisson

The caisson which is open at the bottom and close at the top and sunk by means of utilizing compressed air is known as a pneumatic caisson. Pneumatic caisson consists essentially of the working chamber, the shaft, and an airlock. This type of caisson is usually made of n inner and outer skin plates with steel trusses or girders to form a box-like structure. It is provided with a cutting steel edge at its bottom to facilitate sinking in the soil. The working chamber, provided in the caisson, is about 3 to 4 m deep and is made airtight by providing an airtight roof. It is meant for working of workmen during the sinking process. Access to the working chamber is made through the shaft and airlock.

The air pressure to be used in the working chamber depends upon the depth. The maximum pressure allowed at a depth of 35 m is 3.75 kg/cm². A normal workman can work for eight hours under a pressure of 1.3 kg/cm2. For greater pressure, the working hour is to be reduced accordingly.

Advantages and Disadvantages of Caissons

Advantages of Caissons

1- Economics

2- Minimizes pile cap needs

3- Slightly less noise and reduced vibrations

4- Easily adaptable to varying site conditions

5- High axial and lateral loading capacity

Disadvantages of Caissons

1- Extremely sensitive to construction procedures

2- Not good for contaminated sites

3- Lack of construction expertise

4- Lack of Qualified Inspectors