Column buckling is a phenomenon in structural engineering that occurs when slender elements under high compression suddenly collapse. Thankfully design measures can be taken to prevent this. Buckling load analysis shows the maximum load the column can resist before buckling. The factors impacting this analysis are element length, geometry stiffness, and the material’s elasticity. Another important nature of the failure mode is that it is instantaneous. This is also the reason why it is so deceptive and dangerous.

What Is Buckling?

- Buckling refers to the deformation in columns when an axial load (usually compressive) is applied.

- It occurs when a structural member or building element, which doesn’t adequately support the provided load, experiences a sudden change in its configuration (shape).

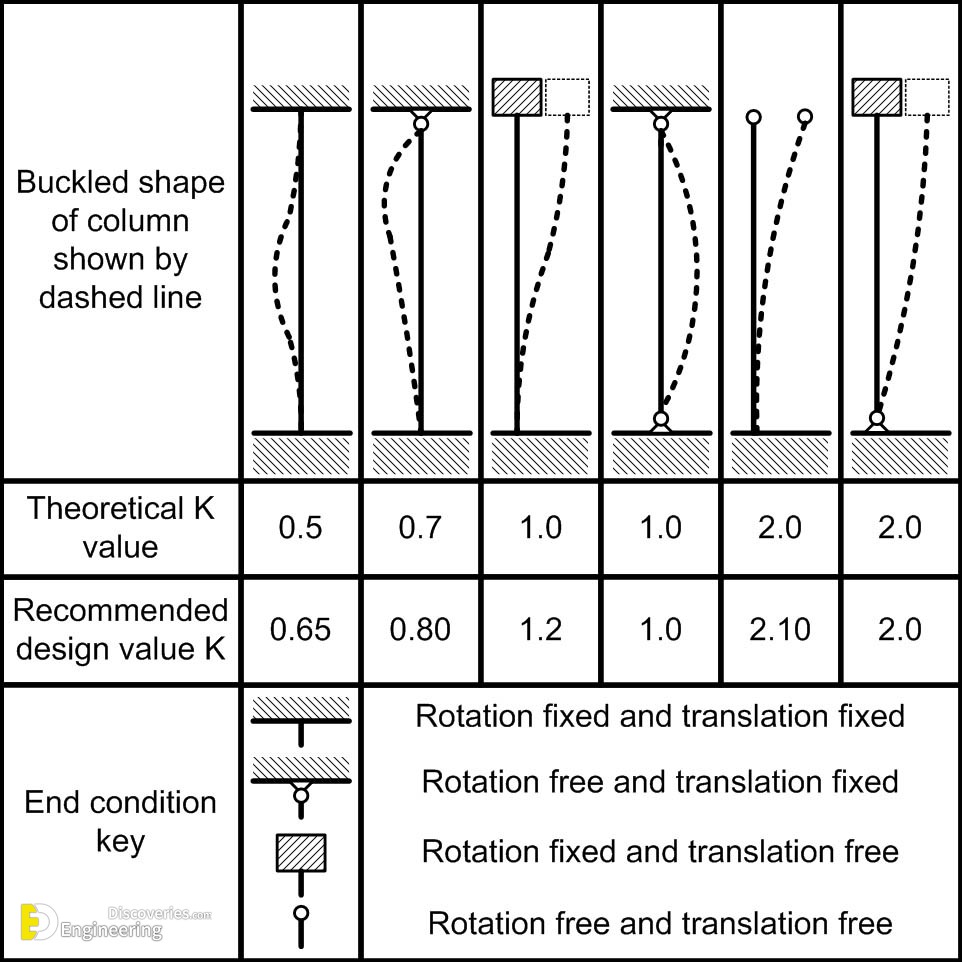

- To understand buckling, we need to grasp the concept of equilibrium stability, which has three stages:

- Unstable equilibrium: Even a small disturbance causes significant movements, and the structure never returns to its original position.

- Neutral equilibrium: It’s challenging to determine whether the structure is in unstable or stable equilibrium. Small disturbances cause large movements, but the structure can be brought back to its original position.

- Stable equilibrium: Small disturbances don’t lead to significant movements, and the structure returns to its original position once the disturbance is removed.

Calculation of Column Buckling

Euler’s formula offers a suitable equation to determine the critical stress, which is the average stress at which a column undergoes buckling. We will delve into Euler’s formula and explore other essential factors in subsequent sections.

The formula is as follows:

σcr=π2EI/(L/r)2

Where:

σcr denotes the critical stress, representing the average stress at which the column buckles.

L refers to the unsupported length of the column.

E signifies Young’s modulus of the material.

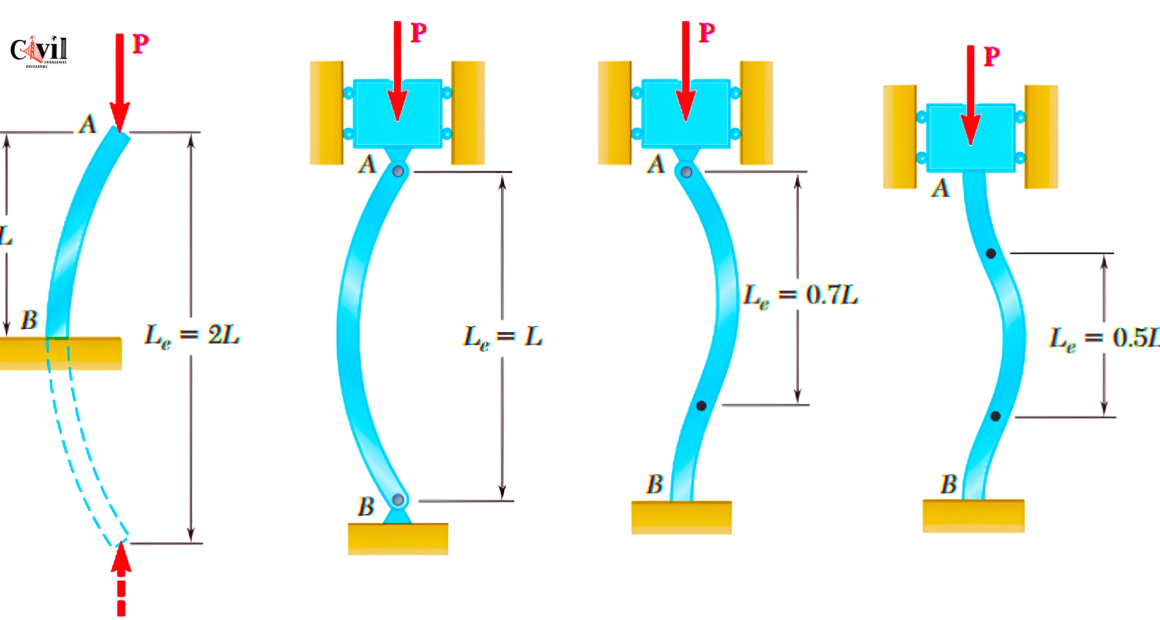

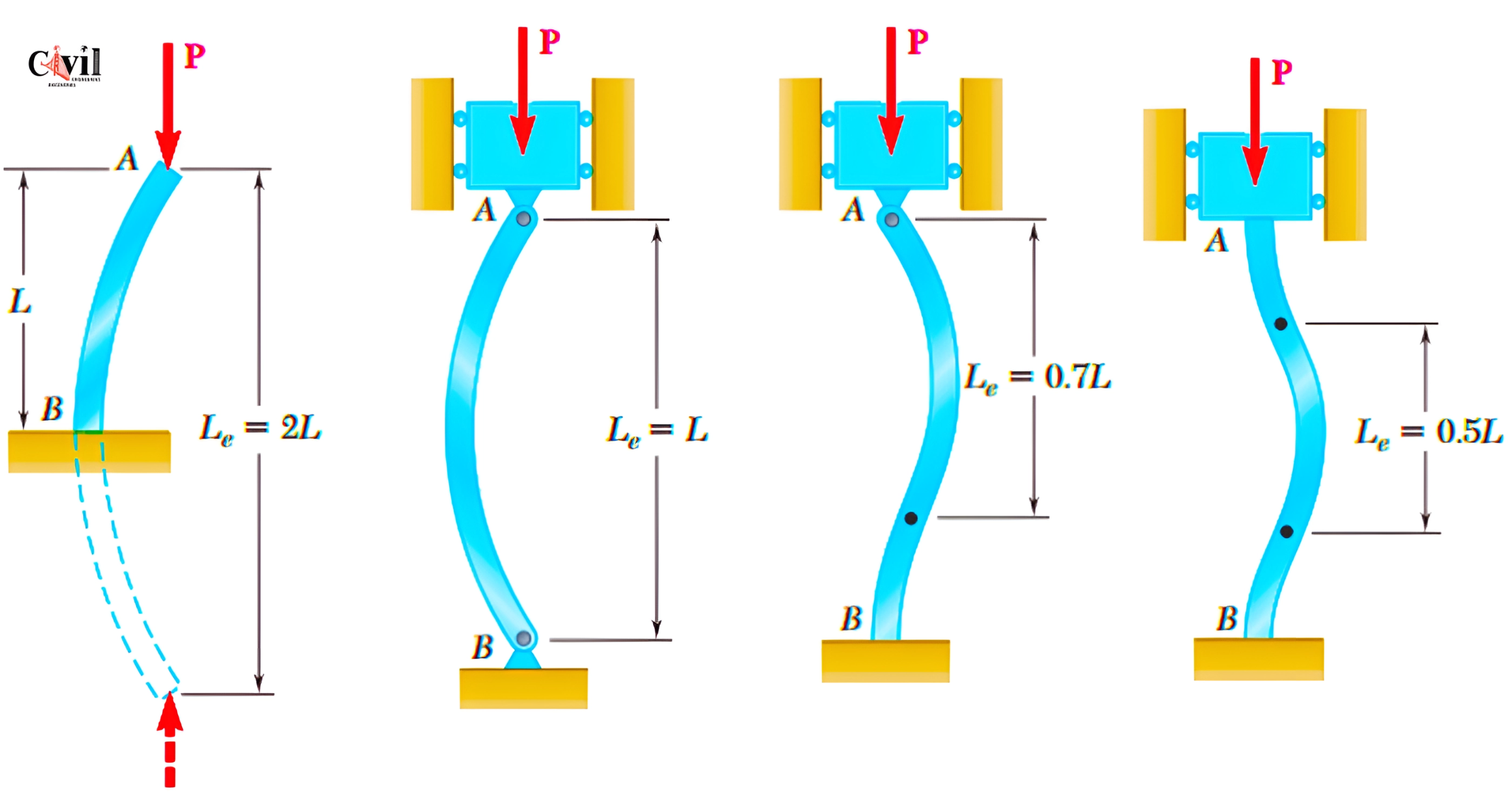

L/r denotes the factor of length, which reflects the end conditions of the column.

Types of Buckling:

- Overall Buckling: Also known as general buckling, this occurs when the entire member experiences distortion or buckling along its longitudinal axis.

- Local Buckling: In local buckling, specific portions of the member (such as flanges or webs) buckle independently.

- Other types include:

- Distortional Buckling: Distortion of the cross-section due to bending effects.

- Lateral Torsional Buckling: A combination of lateral bending and twisting.

- Torsional Flexural Buckling: Twisting combined with bending.

- Global Buckling: Buckling of the entire structure.

- Flexural Buckling: Bending-induced buckling.

Overall buckling capacity significantly influences the design of compressive members. Understanding these buckling modes helps engineers ensure structural stability and prevent premature failure.