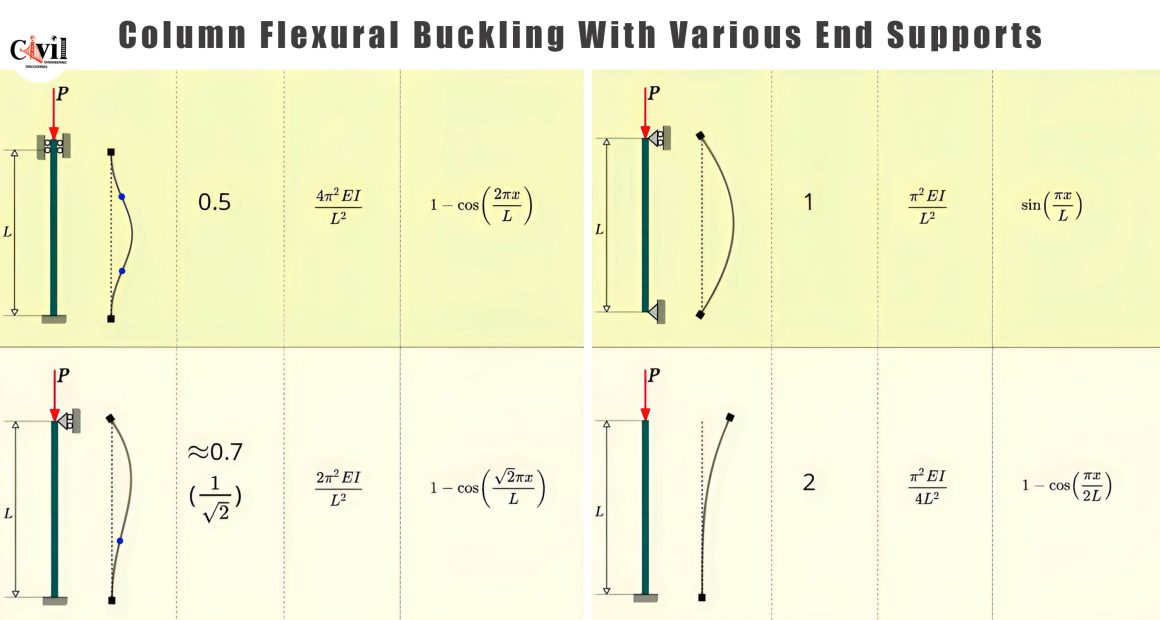

Column flexural buckling is a critical phenomenon that affects the stability and structural integrity of columns subjected to axial compressive forces. When a column is compressed, it can bend or buckle due to the instability caused by external forces. The degree of buckling depends on various factors, including the column’s geometry, material properties, and most importantly, its end supports. Understanding the behavior of columns under different support conditions is essential for engineers to design safe and reliable structures.

Understanding Flexural Buckling

Flexural buckling occurs when the axial compressive force exceeds the column’s critical load, leading to lateral displacement or deflection. This lateral deformation compromises the column’s ability to carry additional loads and may result in structural failure if not adequately addressed. The critical buckling load, often represented by Pcr, is influenced by factors such as column length, cross-sectional area, and moment of inertia.

Mathematically, the critical load for a column can be determined using Euler’s formula for buckling:

Pcr = (π²EI)/(KL)²

Where:

- Pcr = Critical buckling load

- E = Modulus of elasticity of the material

- I = Moment of inertia of the column cross-section

- K = Effective length factor, which depends on end conditions

- L = Actual length of the column

The key factor here is the effective length factor (K), which varies depending on the type of end support provided to the column.

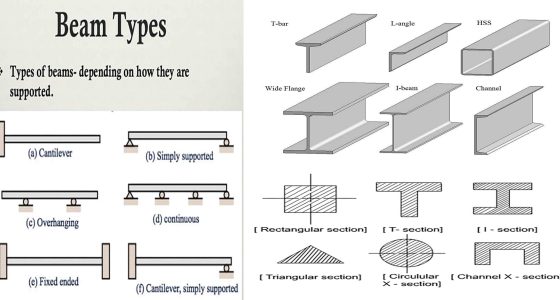

Types of End Supports and Their Effect on Buckling

Different types of end support dramatically influence a column’s ability to resist buckling.

Influence of Column Slenderness Ratio

Apart from end conditions, the slenderness ratio of a column also plays a pivotal role in its buckling behavior. The slenderness ratio is defined as the ratio of the column’s effective length to its radius of gyration (r):

λ=KL/

- λ < 40: The column is considered short, and buckling is not the primary mode of failure. Instead, the column may fail by material yielding.

- λ > 100: The column is slender, and buckling is the dominant failure mode.

- 40 < λ < 100: The column is considered intermediate, and both yielding and buckling need to be considered in the design.

High slenderness ratios indicate that the column is more prone to buckling, especially under compressive forces.

Preventing Buckling Failure

To prevent buckling, engineers can take several approaches:

- Increase the column’s cross-sectional area,

- Use materials with higher modulus of elasticity,

- Reduce the unsupported length of the column,

- Choose appropriate end support conditions that increase stability.

Conclusion: Importance of End Supports in Buckling Analysis

Column buckling is a crucial factor in the design of load-bearing structures. The type of end support dramatically influences the critical buckling load and the overall stability of the column. Understanding how different support conditions—whether pinned, fixed, or cantilever—affect a column’s performance enables engineers to make informed decisions that ensure structural safety.

When designing columns, careful consideration of both the end support conditions and the slenderness ratio is essential to prevent premature buckling and ensure that the structure can withstand the required loads.

Click Here To See Concrete Strength: Cube Strength vs. Cylinder Strength