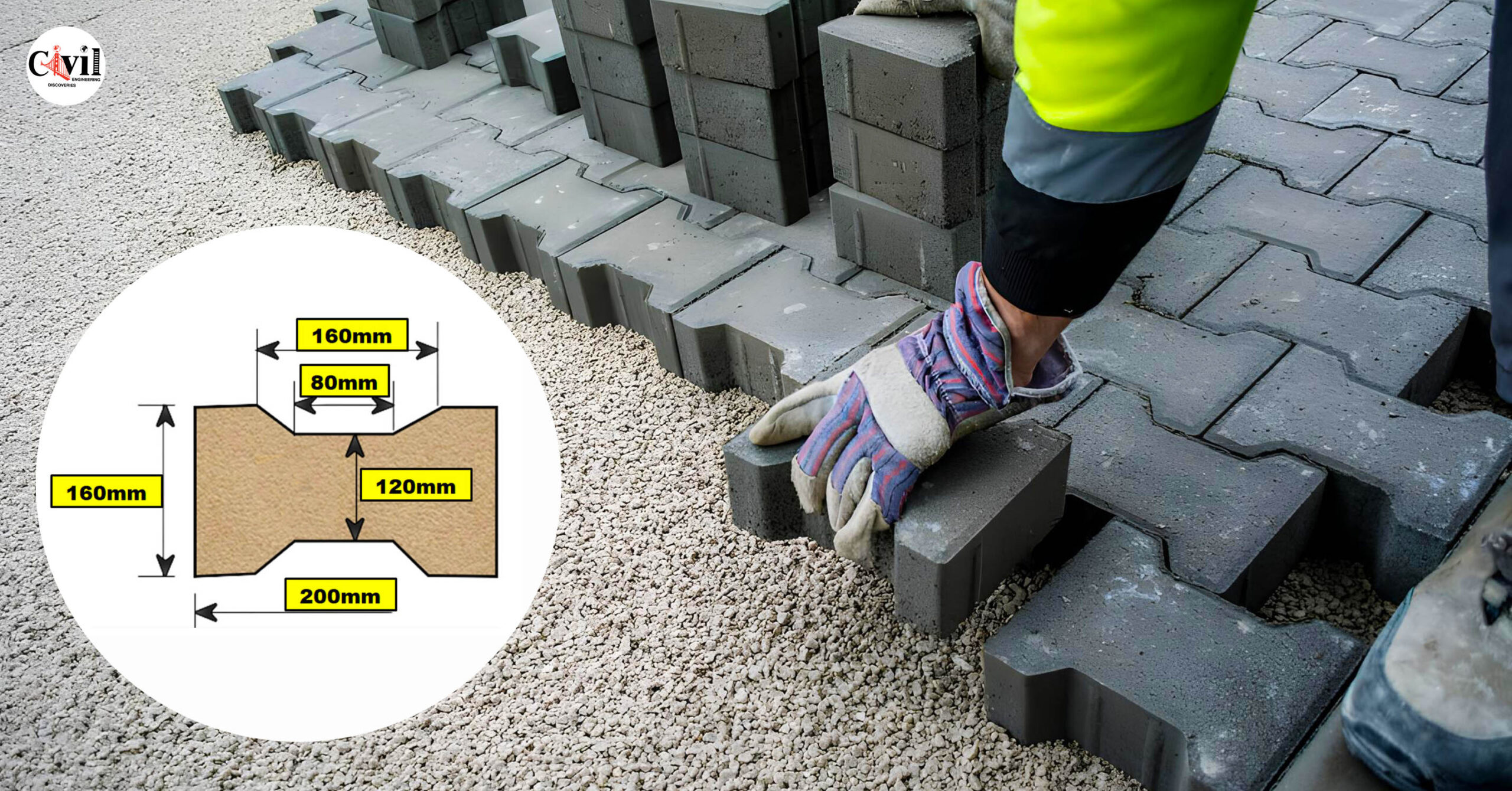

Calculating paver block quantities accurately saves money and prevents project delays. Moreover, proper calculation ensures you order the right amount of materials. This comprehensive guide walks you through each step of the calculation process.

Understanding Paver Block Calculations

Paver block quantity calculation involves determining the total area and individual block coverage. Additionally, you must account for waste factors and cutting requirements. Furthermore, accurate measurements prevent costly material shortages during installation.

Step 1: Calculate Total Project Area

First, measure the length and width of your paving area. Then, multiply these dimensions to get the total square footage. For example, if your area measures 100 feet by 20 feet, the calculation becomes:

Total Area = Length × Width

- Total Area = 100 × 20 = 2,000 square feet

Always double-check your measurements before proceeding. Additionally, consider any irregular shapes that may require separate calculations.

Step 2: Determine Individual Block Area

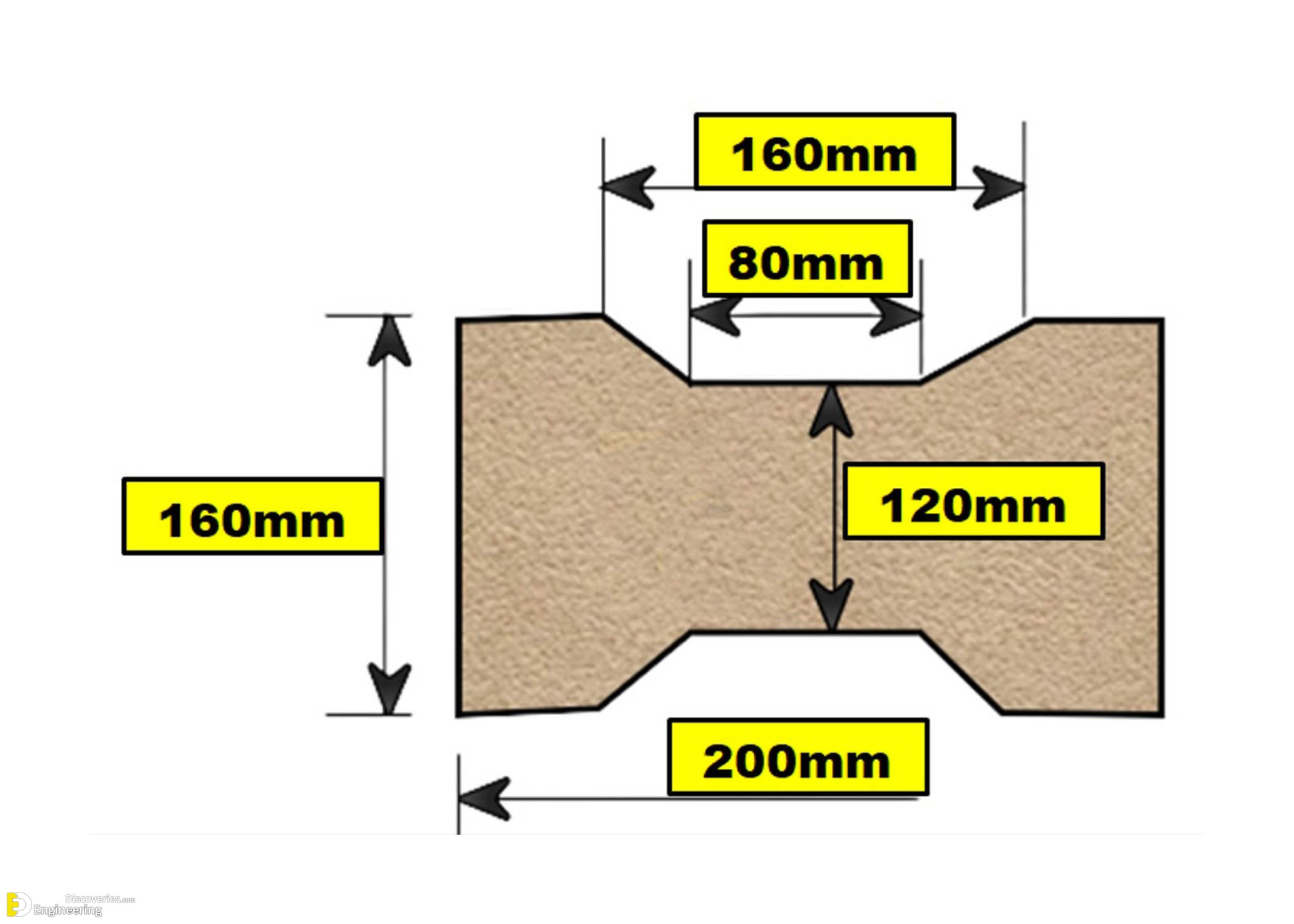

Next, calculate the effective area of each paver block. Standard paver blocks typically measure 200mm × 160mm. However, you must account for joint deductions in your calculations.

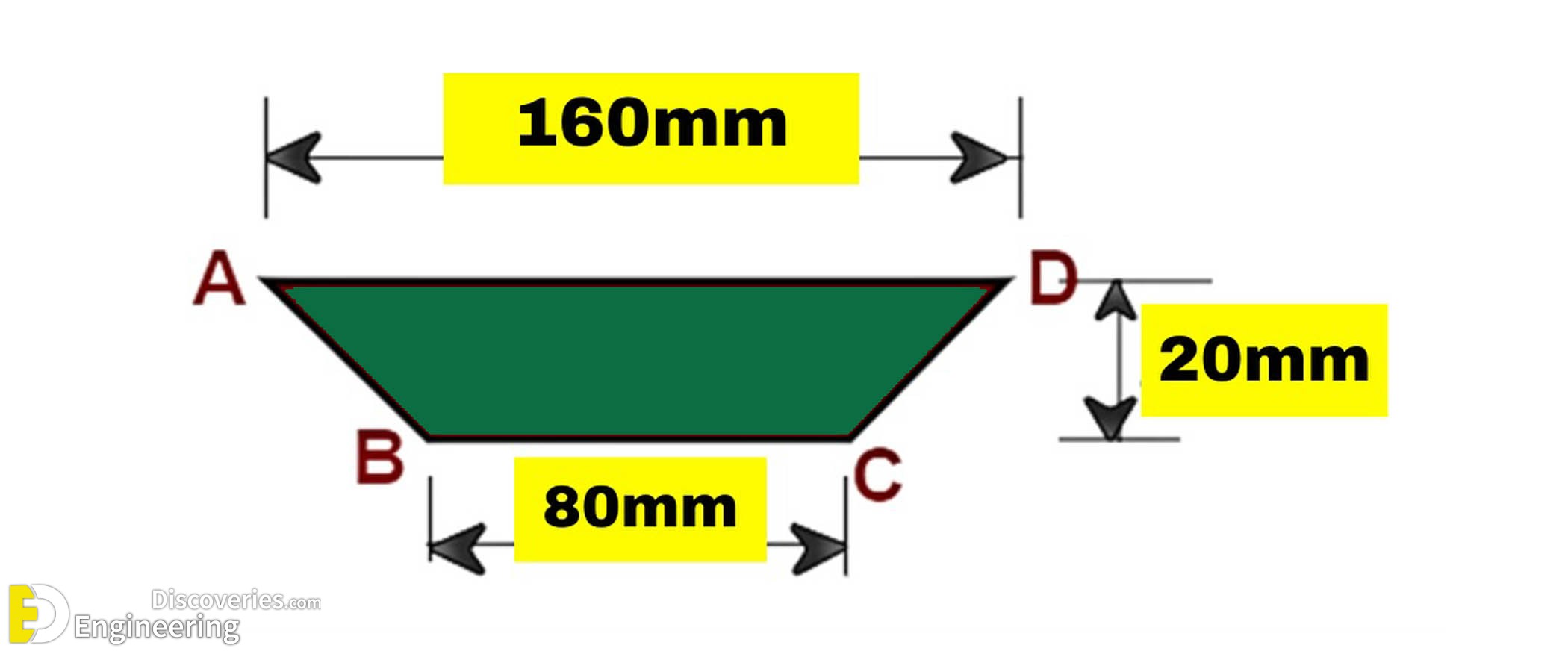

Block Dimension Calculation

- Block Area = 0.200 × 0.160 = 0.032 square meters

Joint Deduction Formula

Subsequently, calculate the deduction for mortar joints:

- Deduction = ((L₁ + L₂) / 2) × B

- Deduction = ((0.08 + 0.160) / 2) × 0.02 = 0.0024 square meters

Effective Block Area

Therefore, the effective area becomes:

- Effective Area = 0.032 – (2 × 0.0024) = 0.0272 square meters

Converting to Square Feet

Since 1 square meter equals 10.76 square feet:

- Block Area = 0.0272 × 10.76 = 0.2926 square feet

Step 3: Calculate Required Block Quantity

Now, divide the total area by the individual block area. This calculation gives you the basic number of blocks needed.

Number of Blocks = Total Area ÷ Block Area

- Number of Blocks = 2,000 ÷ 0.2926 = 6,834 blocks

Step 4: Add Waste Factor

Construction projects always require extra materials for waste and breakage. Depending on project complexity, add 5% to 10% waste factor.

Calculating 5% Waste

- Waste Quantity = (6,834 × 5) ÷ 100 = 342 blocks

Final Block Count

- Total Blocks Required = 6,834 + 342 = 7,176 blocks

Important Calculation Considerations

Several factors affect your final block count. Consequently, consider these variables during planning:

Pattern Complexity: Intricate patterns require more cutting and waste. Therefore, increase your waste factor accordingly.

Site Conditions: Uneven surfaces may require additional blocks for adjustments. Furthermore, difficult access areas often increase breakage rates.

Block Quality: Higher quality blocks typically have lower breakage rates. However, budget blocks may require higher waste factors.

Common Calculation Mistakes to Avoid

Many contractors make simple errors that lead to material shortages. First, always verify your area measurements twice. Second, don’t forget to include waste factors in your calculations.

Additionally, consider these common oversights:

- Failing to account for curved edges

- Ignoring elevation changes

- Underestimating cutting waste

- Not considering delivery breakage

Tips for Accurate Measurements

Precise measurements ensure accurate calculations. Use a quality measuring tape for all dimensions. Moreover, measure multiple times to confirm accuracy.

Best Practices:

- Measure in consistent units throughout

- Account for slopes and grade changes

- Include border and edge treatments

- Document all measurements clearly

Professional Estimation Techniques

Experienced contractors often use digital tools for complex calculations. Furthermore, CAD software can provide precise area calculations for irregular shapes. However, manual calculations work perfectly for standard rectangular areas.

Material Ordering Strategy

Order blocks in phases for large projects. Initially, order 70% of calculated quantities. Then, assess actual usage rates before ordering remaining materials. This approach prevents over-ordering while ensuring adequate supply.

Quality Control During Installation

Monitor block usage throughout installation. Track actual consumption rates against calculated estimates. Consequently, adjust future orders based on real-world usage patterns.

Click Here To See What Is The Void Ratio Of Soil? Significance And Formula Explained