Reinforced Cement Concrete (RCC) beams are essential structural elements in modern construction. A well-designed RCC beam ensures buildings’ stability, safety, and longevity. This guide will walk you through the most important checks required for RCC beam design, covering aspects like support conditions, load types, dimensions, and more.

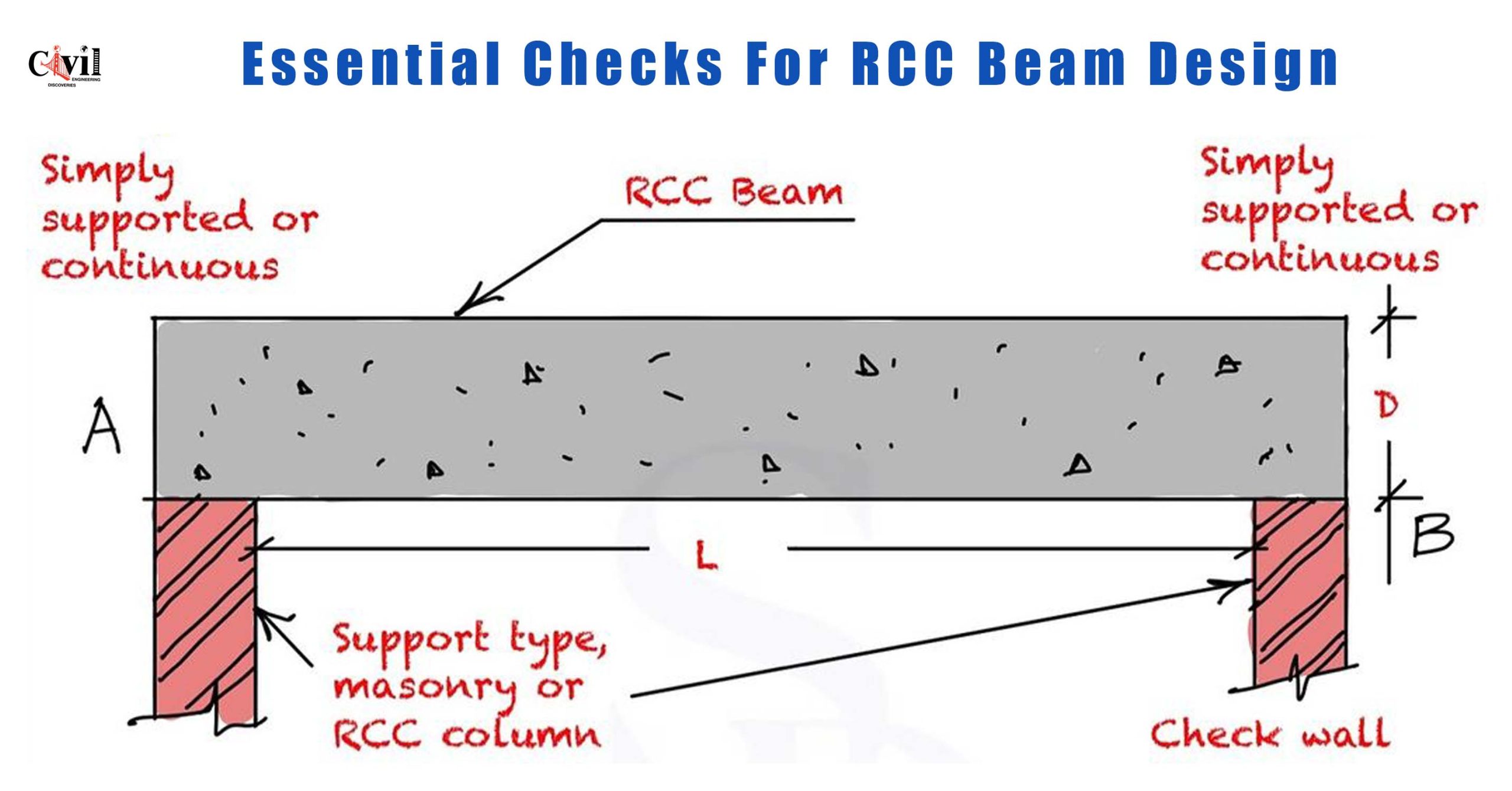

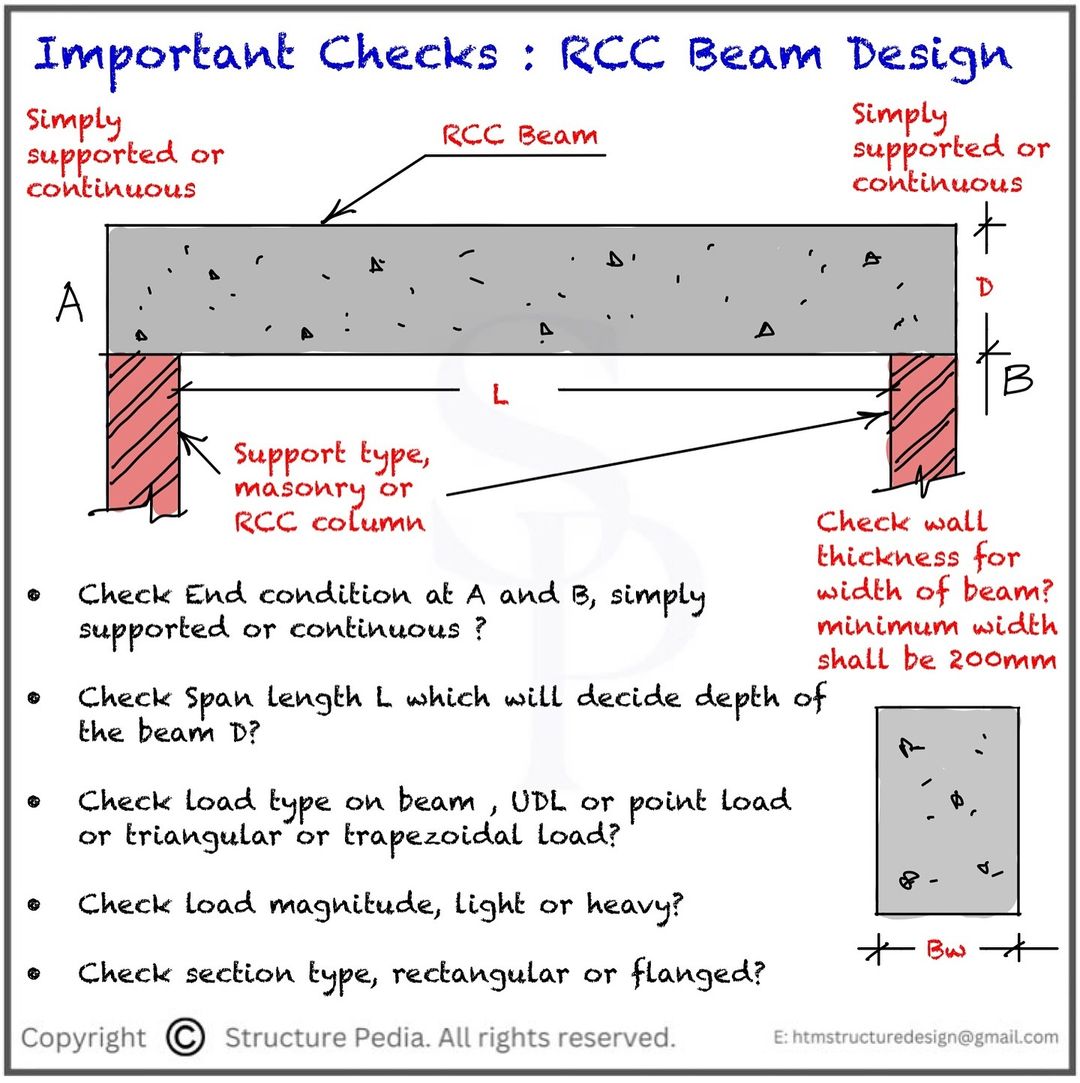

1. Determine the End Condition: Simply Supported or Continuous?

One of the first steps in RCC beam design is determining the end condition. Beams can be either simply supported or continuous. A simply supported beam is supported at both ends without any restraint to rotation, while a continuous beam extends over multiple supports. Understanding the end condition is crucial, as it directly impacts the distribution of forces and the beam’s overall behavior under load.

2. Check Span Length (L) and Its Effect on Beam Depth (D)

The span length (L) is the distance between the beam’s supports. This distance is critical in deciding the depth of the beam (D), which affects its load-bearing capacity. Longer spans usually require deeper beams to avoid excessive deflection. Engineers must ensure that the chosen depth provides sufficient structural strength without compromising architectural requirements.

3. Identify Load Type: Uniformly Distributed Load (UDL) or Point Load?

Different load types affect the design of RCC beams. Common load types include:

- Uniformly Distributed Load (UDL): The load is spread evenly across the beam length.

- Point Load: Load is concentrated at a single point along the beam.

- Triangular Load: Load increases linearly from one end to the other.

- Trapezoidal Load: Load varies but has two distinct values at either end.

Each load type requires specific calculations to ensure the beam’s stability and durability.

4. Assess Load Magnitude: Light or Heavy Load?

Another essential factor in RCC beam design is the magnitude of the load a beam needs to support. Light loads might require less reinforcement, whereas heavy loads demand increased depth and width for structural integrity. Accurately determining load magnitude is necessary to avoid either over-reinforcement or under-reinforcement, both of which can compromise safety.

5. Determine Beam Width and Check Minimum Requirements

To ensure that an RCC beam is structurally sound, it is essential to verify the minimum width requirement. Generally, the minimum beam width should be 200mm. This width check is critical for maintaining stability, especially in walls where beams are embedded. Failing to meet the minimum width can compromise the load distribution and safety of the structure.

6. Select the Appropriate Section Type: Rectangular or Flanged

RCC beams can be designed in different section types based on the structural and architectural needs:

- Rectangular Beams: Commonly used for straightforward structural requirements.

- Flanged Beams: These have an extended flange, often forming a “T” or “L” shape, and are ideal for providing additional support in floor and roof structures.

The choice between a rectangular and flanged section depends on the load requirements and the architectural design of the building.

7. Verify the Type of Support: Masonry or RCC Column

The support type at each end of the beam affects the load transfer to other structural elements. RCC columns are preferred in modern buildings for their strength and durability, but beams can also be supported by masonry walls, especially in smaller constructions. Knowing the support type helps in calculating the distribution of forces within the structure accurately.

Photo Credit: StructurePedia