Reinforced Cement Concrete (RCC) beams are a fundamental part of modern construction. They are designed to withstand a combination of different loads. However, despite their strength, RCC beams can experience failure if not designed or executed properly. There are two major types of failure in RCC beams: Flexure Failure and Shear Failure. Both types of failures can severely compromise the safety and durability of a structure. In this article, we will explore these failures in detail, focusing on their causes, mechanisms, and potential remedies.

1. What is Flexure Failure in RCC Beams?

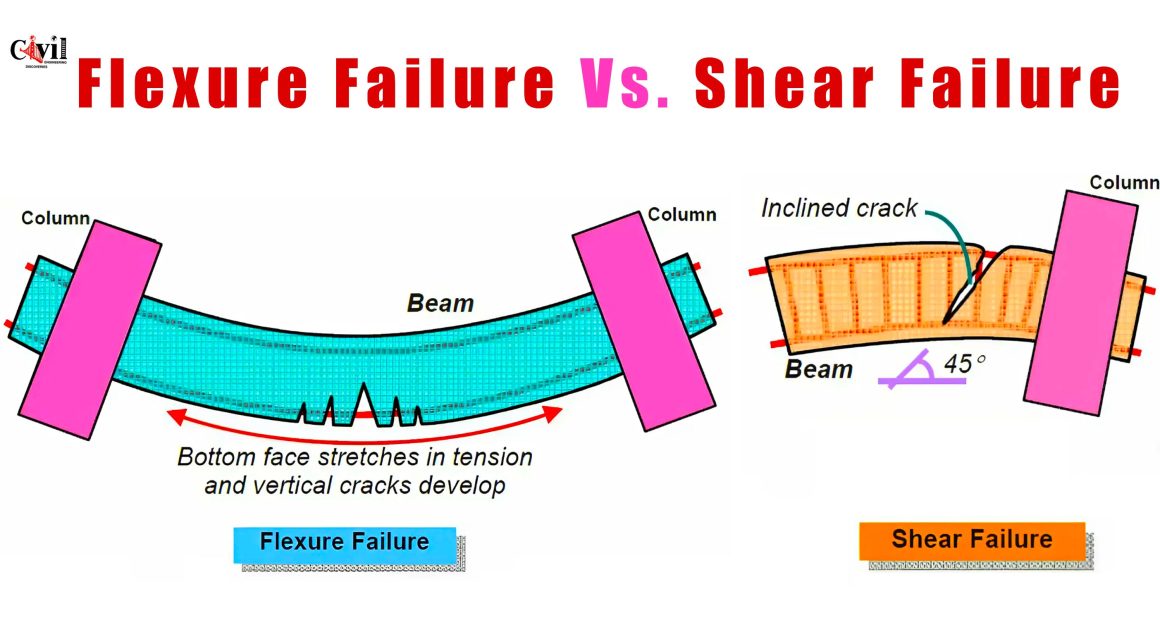

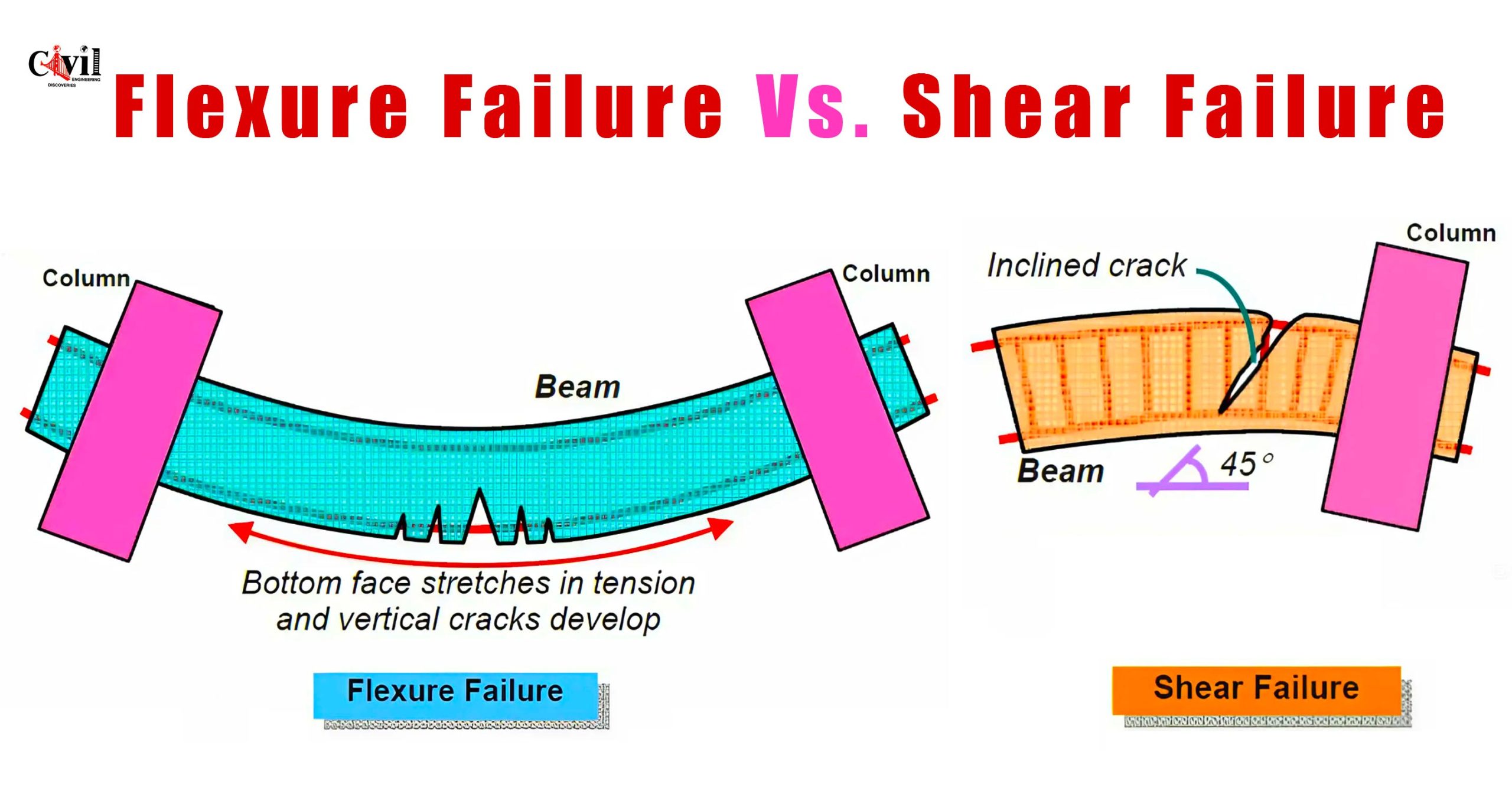

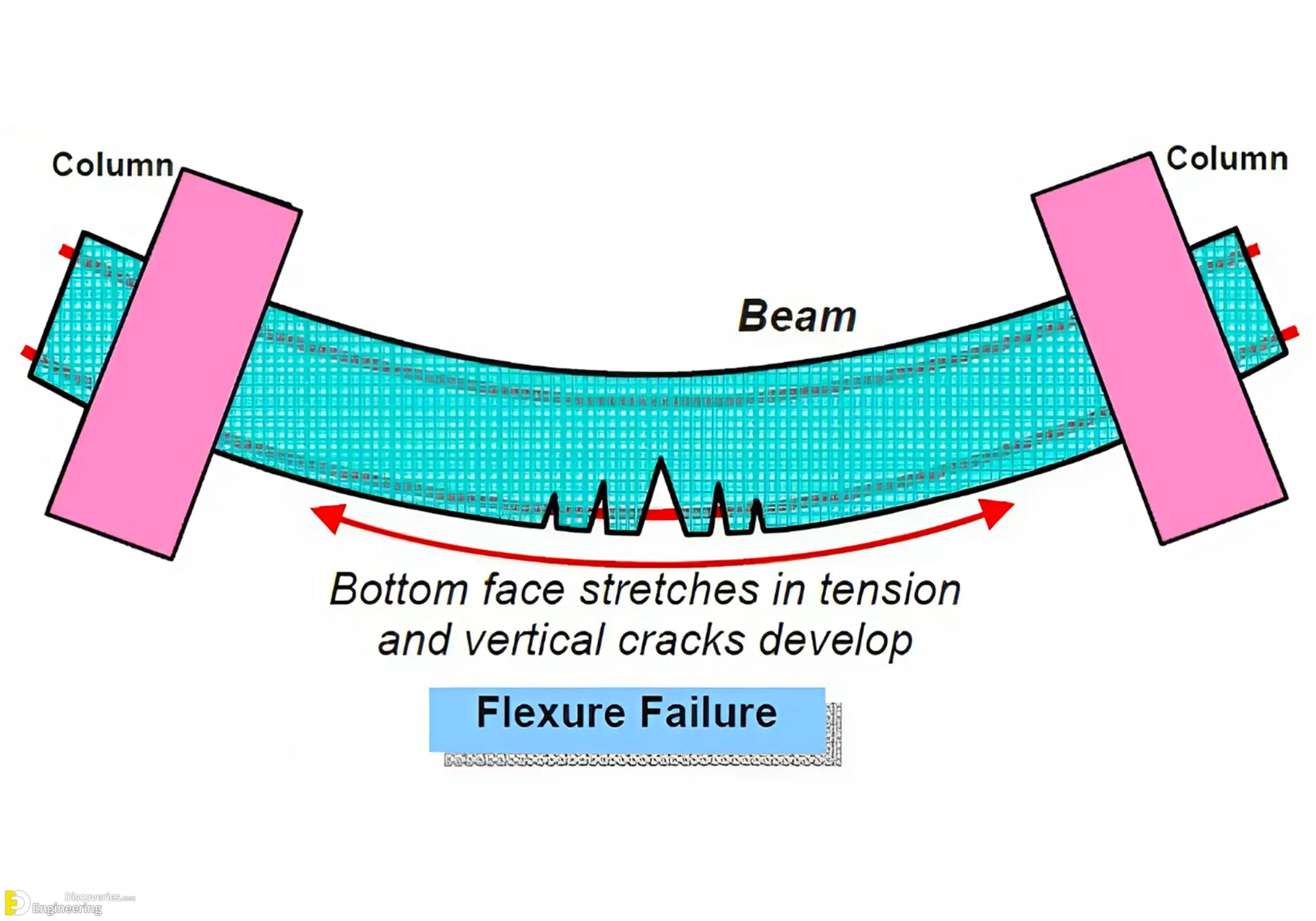

Flexure failure occurs when an RCC beam cannot handle the bending stresses applied to it. When the bending moment exceeds the beam’s capacity, the tension reinforcement in the beam begins to yield, leading to flexural failure. This type of failure is most common in beams designed to carry heavy loads but where inadequate reinforcement or poor design principles have been used.

Causes of Flexure Failure

Several factors can contribute to flexure failure in RCC beams, including:

- Inadequate Reinforcement: If the tension reinforcement provided in the beam is insufficient, the beam may not be able to handle the bending moment, leading to failure.

- Poor Concrete Quality: Low-grade concrete or poor mixing ratios can reduce the strength of the beam, making it more susceptible to failure.

- Overloading: When the beam is subjected to loads that exceed its design capacity, it is likely to fail in flexure.

- Inadequate Beam Depth: The depth of the beam plays a crucial role in its bending resistance. A beam that is too shallow may fail under bending stress.

- Inaccurate Load Distribution: If the loads are not distributed as assumed in the design phase, flexural failure may occur.

Mechanism of Flexure Failure

In flexural failure, cracks first appear at the tension face of the beam, which is the bottom side in simply supported beams. These cracks tend to propagate vertically as the load increases. When the tensile stress in the reinforcement steel reaches the yield point, the steel deforms plastically. As the load continues to increase, the beam undergoes large deflections until the concrete in the compression zone crushes, leading to failure.

Preventing Flexure Failure

- Proper Reinforcement Design: Ensure that the beam is adequately reinforced to resist bending stresses. This includes proper sizing, placement, and spacing of rebars.

- Use of High-Strength Materials: The use of high-quality concrete and steel with appropriate strengths can greatly reduce the chances of flexure failure.

- Adherence to Load Specifications: Ensure that the beam is designed and constructed to handle the anticipated loads without overloading.

- Sufficient Beam Depth: Adequate beam depth is critical to providing resistance against bending moments.

2. What is Shear Failure in RCC Beams?

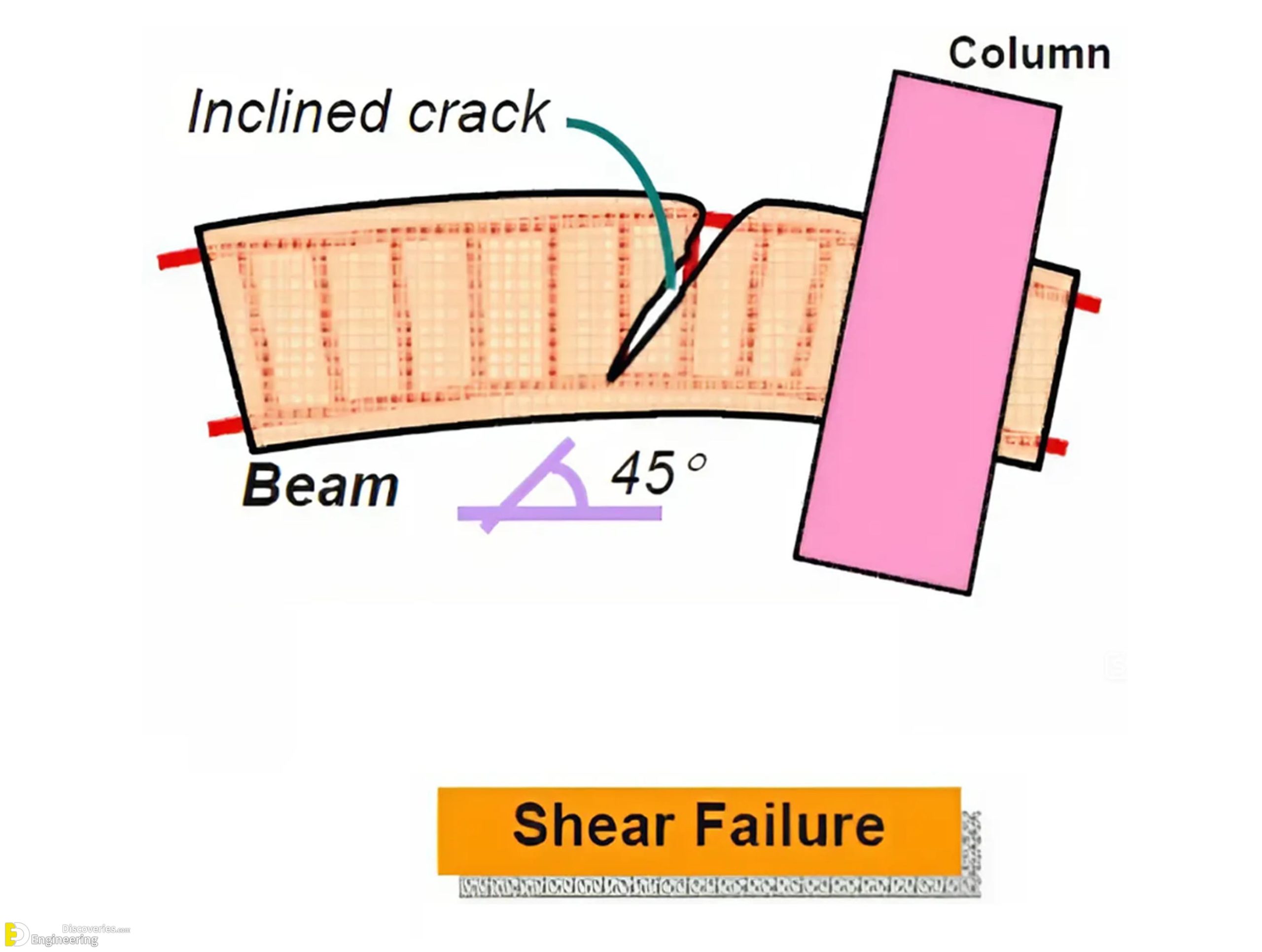

Shear failure, on the other hand, occurs when the beam is unable to withstand the shear stresses, which are caused by the loads acting perpendicular to the axis of the beam. Unlike flexure failure, shear failure is a more sudden and brittle form of failure, giving little warning before collapse. In many cases, shear failure occurs due to poor design or insufficient shear reinforcement, such as stirrups.

Causes of Shear Failure

Some of the common causes of shear failure in RCC beams are:

- Inadequate Shear Reinforcement: Insufficient shear reinforcement, like stirrups, can lead to the development of shear cracks.

- Improper Placement of Stirrups: If stirrups are not properly placed along the length of the beam, certain sections may be left vulnerable to shear failure.

- Low-Strength Concrete: Poor-quality concrete with low compressive strength can be more prone to shear failure.

- High Concentrated Loads: Concentrated or point loads can cause significant shear stresses, which can lead to failure if the beam is not properly designed.

- Short Span Beams: Beams with short spans are more susceptible to shear failure since the shear forces are higher in shorter beams.

Mechanism of Shear Failure

In a shear failure scenario, diagonal cracks begin to form near the supports or within the middle third of the beam. These cracks develop due to the high shear forces acting on the section. If not adequately reinforced, these cracks will propagate towards the compression zone. Once the cracks extend far enough, the beam fails by splitting into two separate sections.

Preventing Shear Failure

- Adequate Shear Reinforcement: Providing sufficient and properly spaced stirrups or shear links along the length of the beam is essential to prevent shear failure.

- High-Strength Concrete: Using concrete with a higher compressive strength can improve the beam’s resistance to shear forces.

- Proper Load Distribution: Ensure that loads are evenly distributed and avoid placing concentrated loads on beam sections where shear forces are likely to be high.

- Increasing Beam Depth: As with flexure, increasing the beam’s depth can reduce the shear stresses acting on it.

Comparison Between Flexure Failure and Shear Failure

Although both flexure and shear failures can occur in RCC beams, they differ significantly in their causes, mechanisms, and warning signs.

- Flexure Failure tends to be a more gradual process, allowing for signs such as cracks and large deflections before the beam collapses.

- Shear Failure, on the other hand, is a more brittle form of failure and often occurs suddenly without much warning.

Flexure failure is generally considered safer because it provides visible signs before the ultimate failure, while shear failure can lead to catastrophic collapse with little warning.