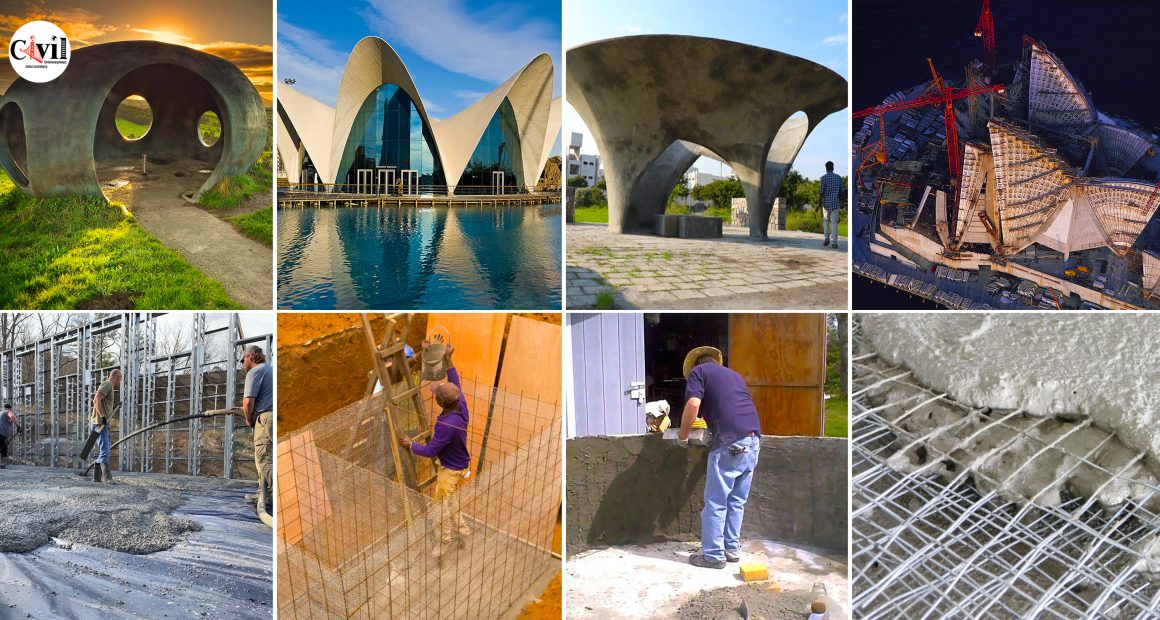

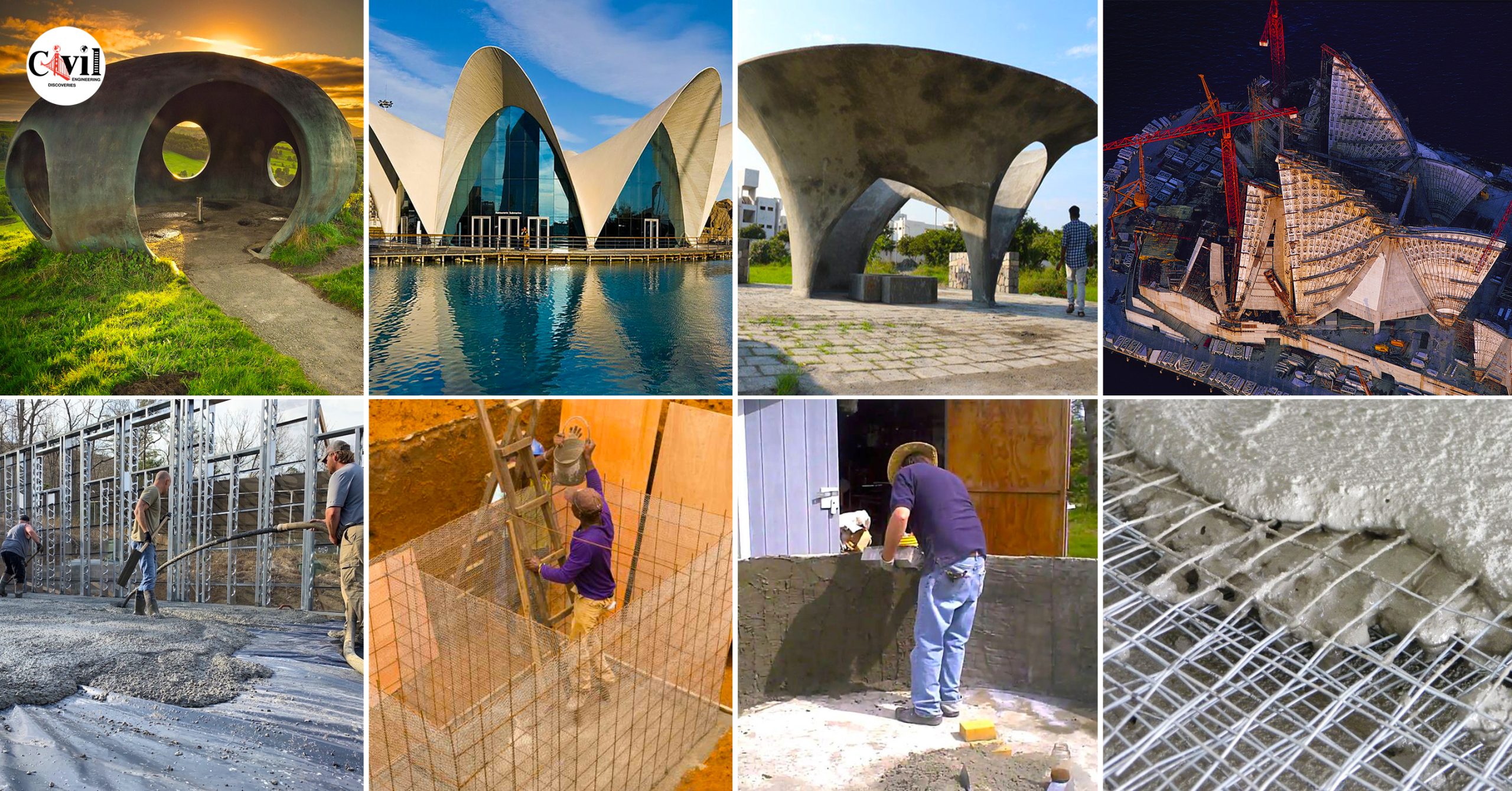

Ferrocement is a type of thin-wall reinforced concrete commonly constructed of hydraulic-cement mortar reinforced with closely spaced layers of continuous and relatively small wire mesh. The mesh may be made of metallic or other suitable materials. Ferrocement has a very high tensile strength-to-weight ratio and superior cracking behavior in comparison to conventional reinforced concrete. Unlike conventional concrete. Ferrocement reinforcement can be assembled into its final desired shape and the mortar can be plastered directly in place without the use of a form.

Materials Used in Ferrocement

- Cement

- Fine Aggregates

- Admixtures

- Steel Wire Meshes

- Skeleton Steel

- Water

Properties

- High Strength: Ferrocement exhibits high tensile and flexural strength due to the presence of multiple layers of wire mesh reinforcement.

- Excellent Durability: It has good resistance to cracking, corrosion, and weathering, making it suitable for various environments.

- Lightweight: Ferrocement is relatively lightweight compared to traditional reinforced concrete, which allows for the construction of thin and curved structures.

- Versatility: It can be molded into different shapes and forms, providing flexibility in design and construction.

Uses

The use of Ferrocement offers advantages such as cost-effectiveness, ease of construction, and the ability to create complex shapes. Its lightweight nature reduces the need for heavy foundations and transportation costs.

Applications

- Building Construction: Ferrocement can be used for a wide range of building applications, including walls, roofs, floors, and partitions.

Water Storage Structures: Ferrocement is commonly used for constructing water tanks, reservoirs, and swimming pools.

Architectural Features: Ferrocement can be used to create aesthetically pleasing architectural features such as domes, arches, and decorative facades.

Retrofitting and Repair: Ferrocement can be employed for retrofitting and repairing existing structures, improving their strength and durability.

Advantages of Ferrocement

01. It has got a higher ratio of tensile strength to weight and superior cracking behavior compared to R.C.C. They comprise thin elements and light structures hence, they are lighter in weight.

02. can be cast in any desired shape and size for a wide range of uses.

03. It provides better resistance to fire, earthquake, and corrosion than traditional materials, such as wood, adobe, and stone masonry in residential construction.

04. The materials are relatively inexpensive, and can usually be obtained locally.

05. Only a few simple hand tools are needed to build uncomplicated structures.

06. Repairs in Ferrocement structure are usually easy and inexpensive which means it has low maintenance cost.

07. It is easy to handle.

08. Ferrocement saves 20% on cost and materials.

09. There’s a reduction in cost economy and speed, both can be achieved.

10. It has less thermal conductivity as compared to RCC.

Disadvantages of Ferrocement

01. Excessive shrinkage occurs due to higher cement content. Thus, it requires constant curing for a period of 7 days to avoid any such shrinkage cracks.

02. It is prone to corrosion of wire mesh due to incomplete coverage of steel by mortar.

03. Ferrocement is labor intensive and hence not a good choice where the labor costs are high.

04. As Ferrocement construction usually has thin structures, buckling is another factor that needs to be taken into consideration.

05. Being thin Ferrocement members, they have poor impact resistance.

06. Structures made of Ferrocement can be punctured by forceful collision with pointed objects.

07. They have low shear strength and low ductility.

08. Ferrocement is susceptible to stress rupture failure.

09. It is hard to do welding, drilling, nailing, screwing, etc. properly in Ferrocement construction.