Introduction to Level Error Checking

In surveying, ensuring the accuracy of leveling equipment is essential. Performing level error checks on auto-level or leveling machines helps achieve precise results. Follow this simple step-by-step procedure to minimize potential discrepancies.

Step 1: Set Up the Level Machine

Begin by setting up your level machine correctly. Make sure it is well-leveled on firm ground. Stability is critical to avoid incorrect readings. Always double-check that the setup follows manufacturer guidelines.

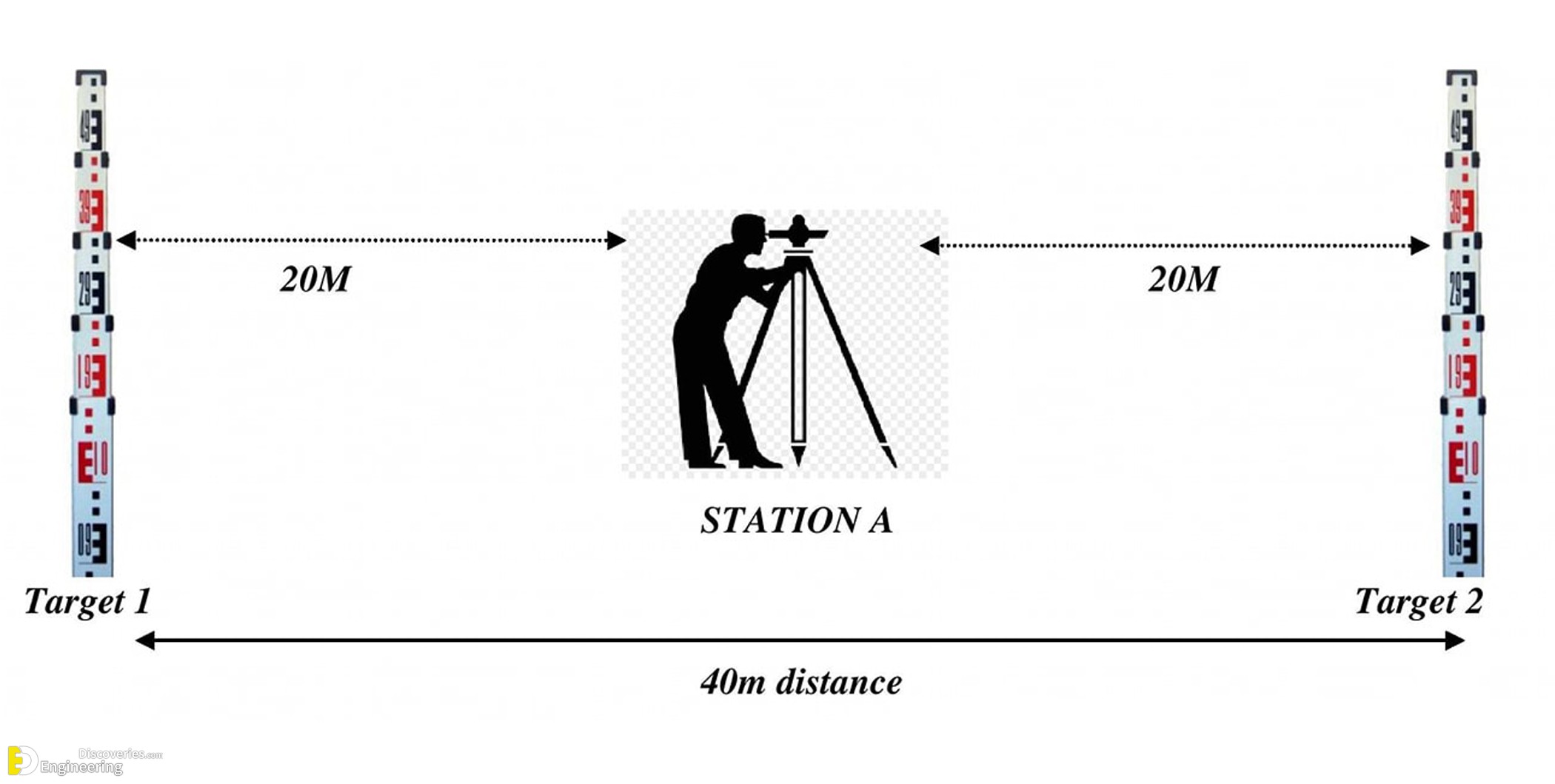

Step 2: Position Staff at Equal Distances

Next, place two staff members 20 meters away from the station on opposite sides. This symmetrical setup ensures balanced readings from both targets.

Step 3: Record Initial Staff Readings from Station A

With the equipment ready at Station A, take staff readings from both Target 1 and Target 2. Record these values carefully.

Example Reading at Station A

| STATION A | Target 1 | Target 2 | Difference (T1 – T2) |

|---|---|---|---|

| For example | 120.00 cm | 186.20 cm | -66.20 cm (120.00 – 186.20) |

Calculate the difference between Target 1 and Target 2 readings. This initial value will be essential for cross-checking accuracy later.

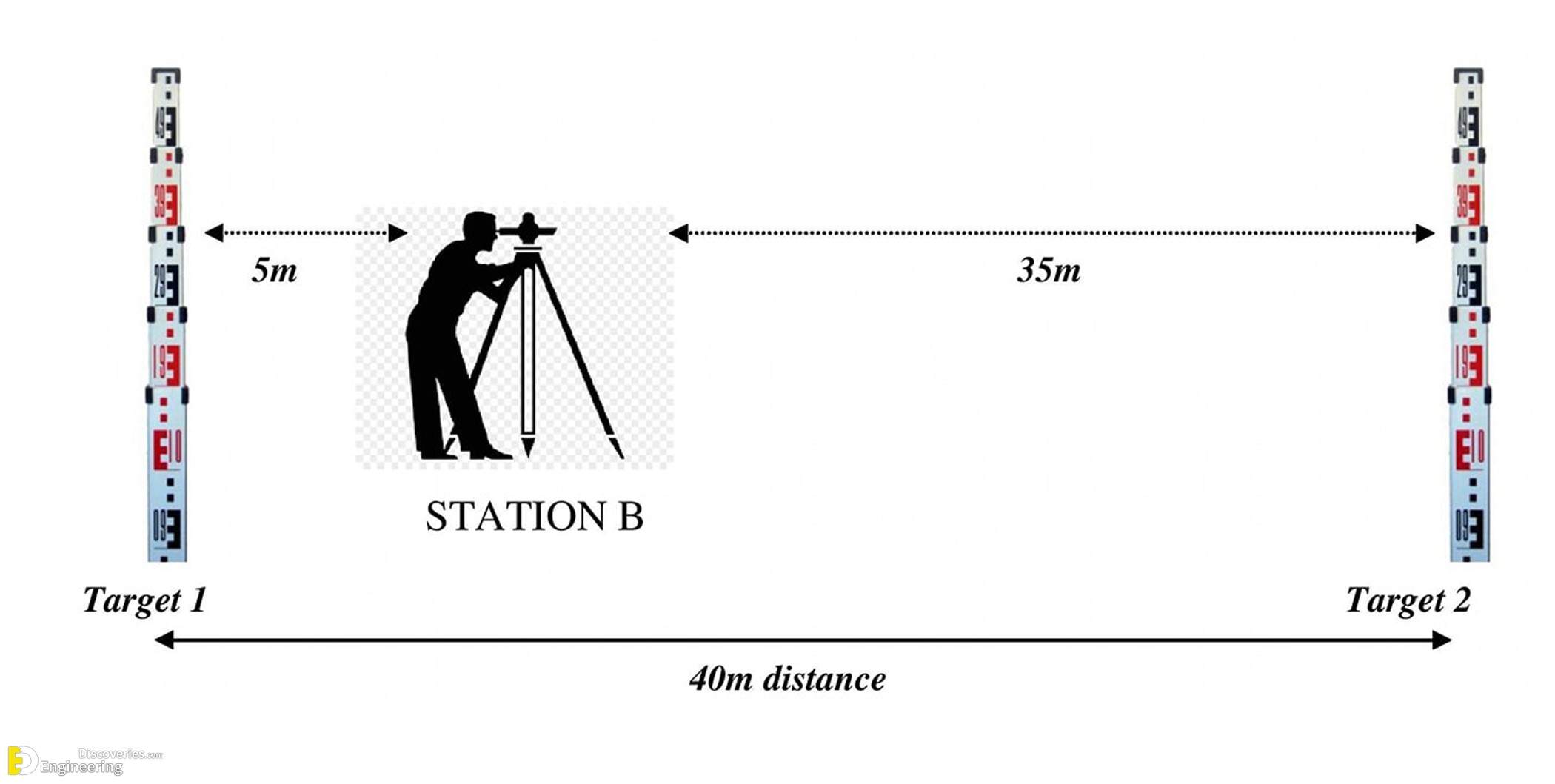

Step 4: Shift to Station B for Verification

Move the level machine to Station B, located approximately 5 meters from one target. Maintain the total distance of 40 meters between the two staff members.

Step 5: Record Staff Readings from Station B

Take new readings from both targets at Station B. Accuracy is key during this phase.

Example Reading at Station B

| STATION B | Target 1 | Target 2 | Difference (T1 – T2) |

|---|---|---|---|

| For example | 117.7 cm | 183.90 cm | -66.20 cm (117.7 – 183.90) |

Again, calculate the difference between the two readings.

Step 6: Analyze the Level Error

Finally, the level error is determined by comparing the differences between Station A and Station B.

Formula:

Difference at Station A – Difference at Station B

= (-66.20) – (-66.20) = 0

A result of zero indicates no error. However, minor 2-3 mm discrepancies are acceptable depending on project precision.

Acceptable Error Margin

An error tolerance of 2-3 mm is generally considered acceptable. However, this range may vary based on specific project requirements or industry standards.

Click Here To See Brief Overview Of Levelling

Thank you for your academic support