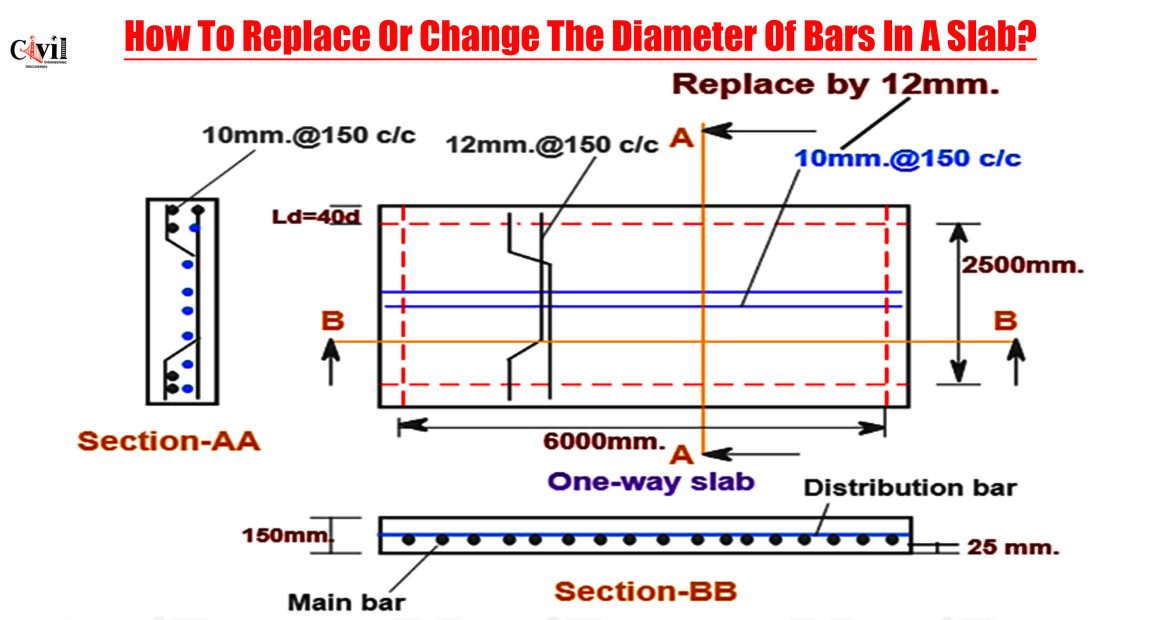

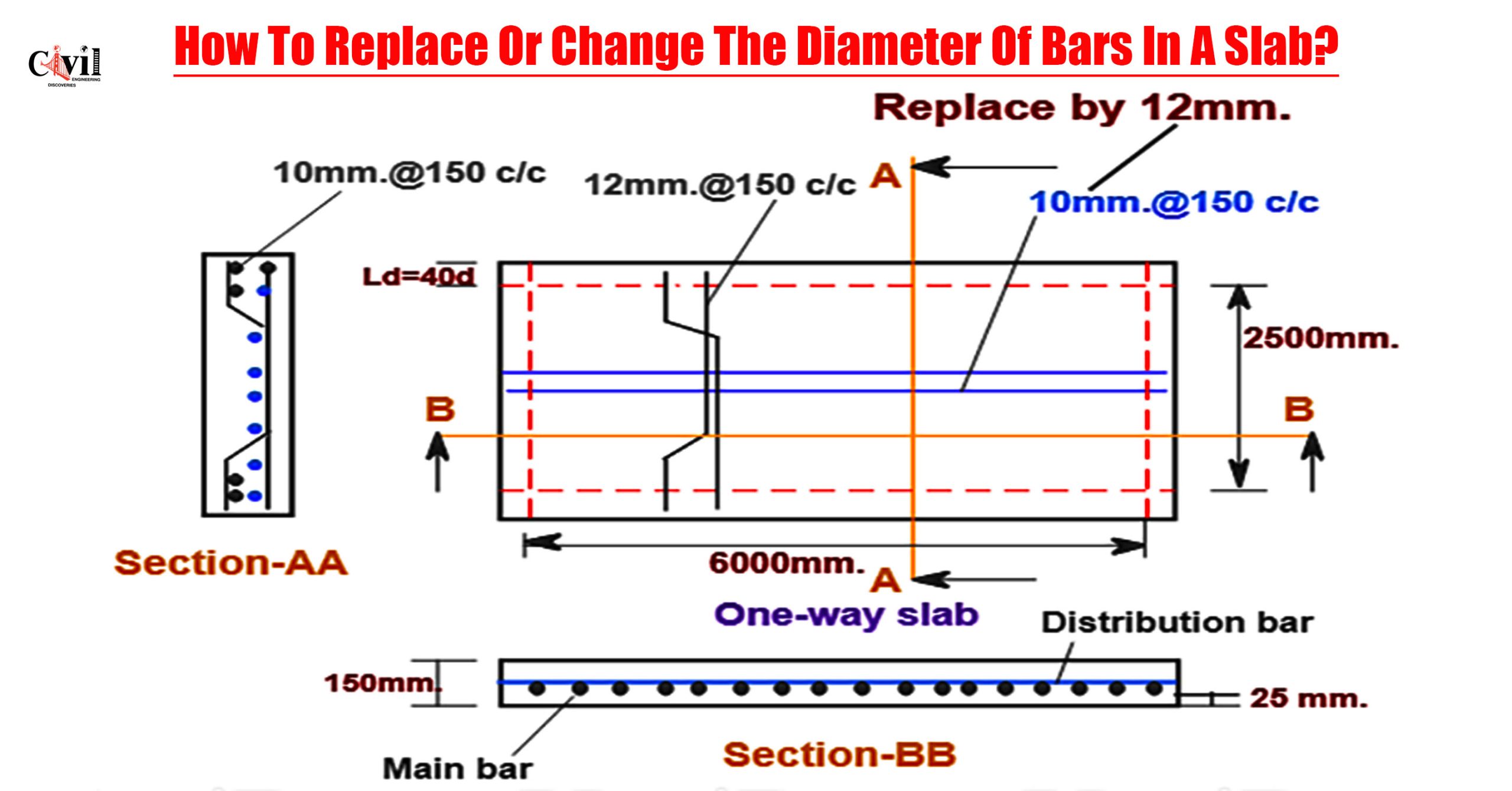

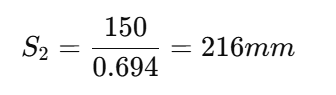

Scenario:

We need to replace a 10mm diameter distribution bar with a 12mm diameter bar due to non-availability.

Given Data:

- Original bar diameter (D₁) = 10mm

- Spacing of 10mm bar (S₁) = 150mm (center-to-center)

Objective:

To calculate the required spacing (S₂) for the 12mm diameter replacement bar.

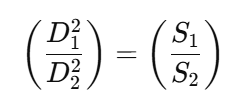

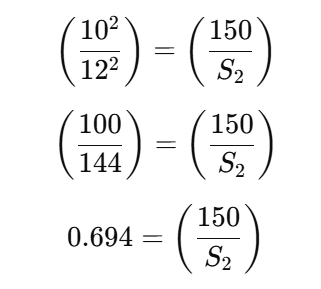

Step 1: Calculate New Spacing

The formula used for spacing adjustment is:

Where:

- D₁ = Diameter of the original bar (10mm)

- D₂ = Diameter of the replaced bar (12mm)

- S₁ = Spacing of the original bar (150mm)

- S₂ = Spacing of the replaced bar (to be determined)

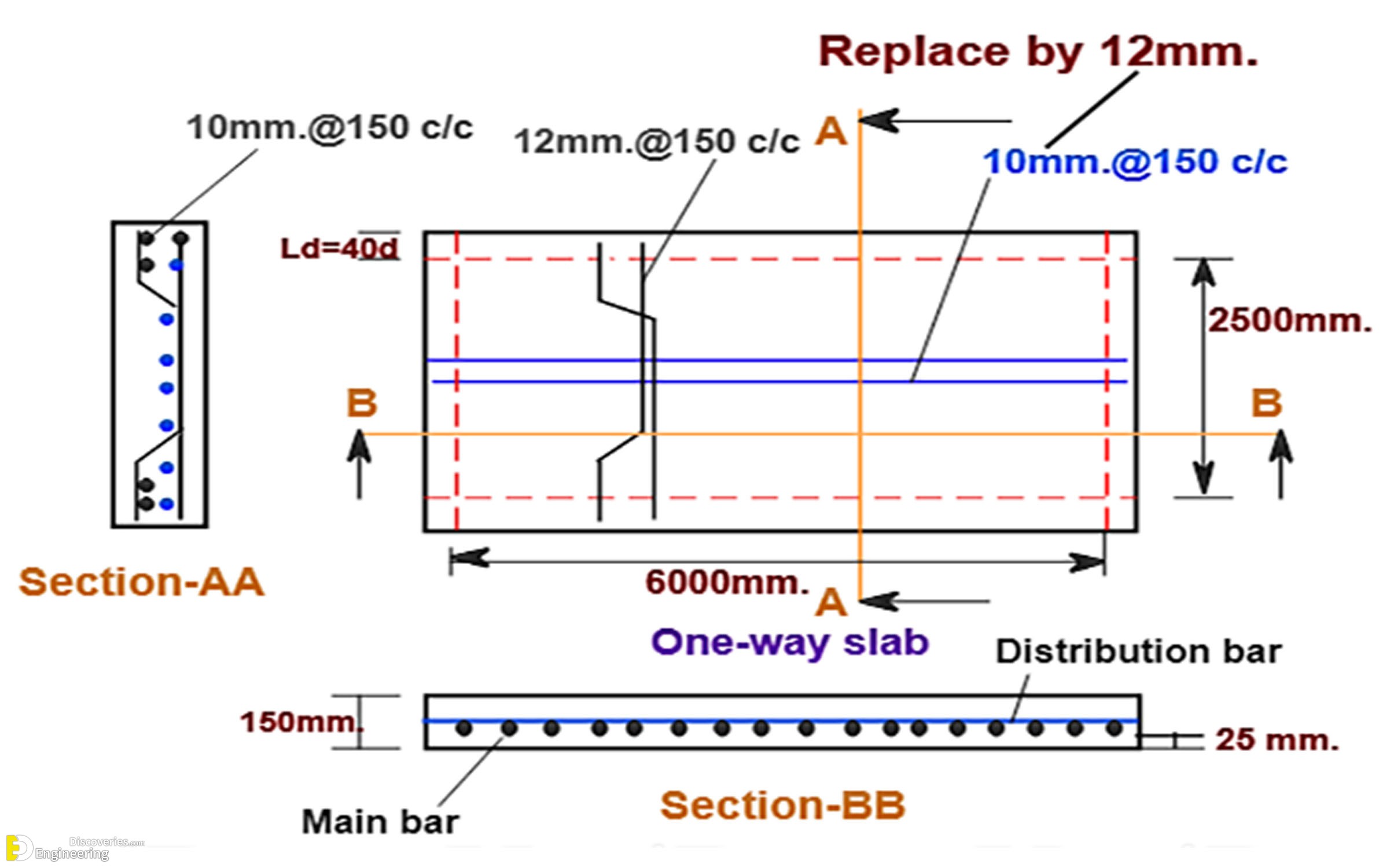

Thus, the 12mm bars should be placed at 216mm center-to-center.

Note:

The new spacing should not exceed the maximum allowable spacing as per the design criteria.

Step 2: Verify the Total Weight of Steel Used

Even though the bar diameter is increased, the total steel weight remains almost the same.

For 10mm bars:

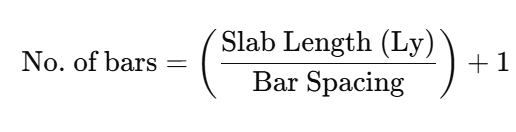

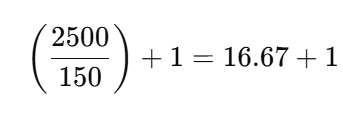

Number of distribution Bars Required

For 10mm bars:

= 17.67

Rounded off to 18 bars.

For 12mm bars:

Number of distribution Bars Required

= 12.57

Rounded off to 13 bars.

Step 3: Compare the Total Weight

Steel weight per meter:

- 10mm bar = 0.62 kg/m

- 12mm bar = 0.88 kg/m

Total weight for 10mm bars = 18 × 0.62 = 11.16kg

Total weight for 12mm bars = 13 × 0.88 = 11.4kg

Since 11.4 kg ≈ 11.16 kg, the weight of steel remains nearly the same.

Conclusion:

- Replacing a 10mm bar with a 12mm bar does not increase the cost because the total weight of steel used remains the same.

- Spacing should be adjusted accordingly to maintain the same reinforcement area and structural strength.

This method ensures efficient material utilization while maintaining structural integrity.

Click Here To See Calculating Steel Replacement In Columns On-Site