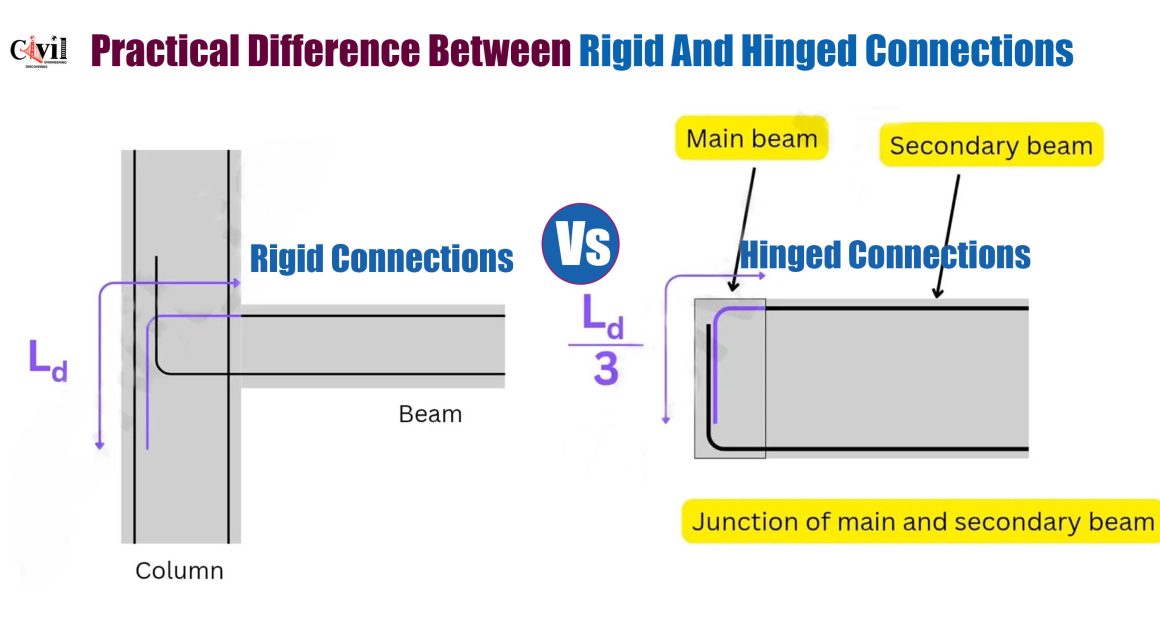

Understanding RCC Connections in Structural Design

Connections play a crucial role in structural engineering, especially in RCC (Reinforced Cement Concrete) construction. Two commonly used types are rigid connections and hinged connections. These affect the structural performance, load transfer, and frame flexibility.

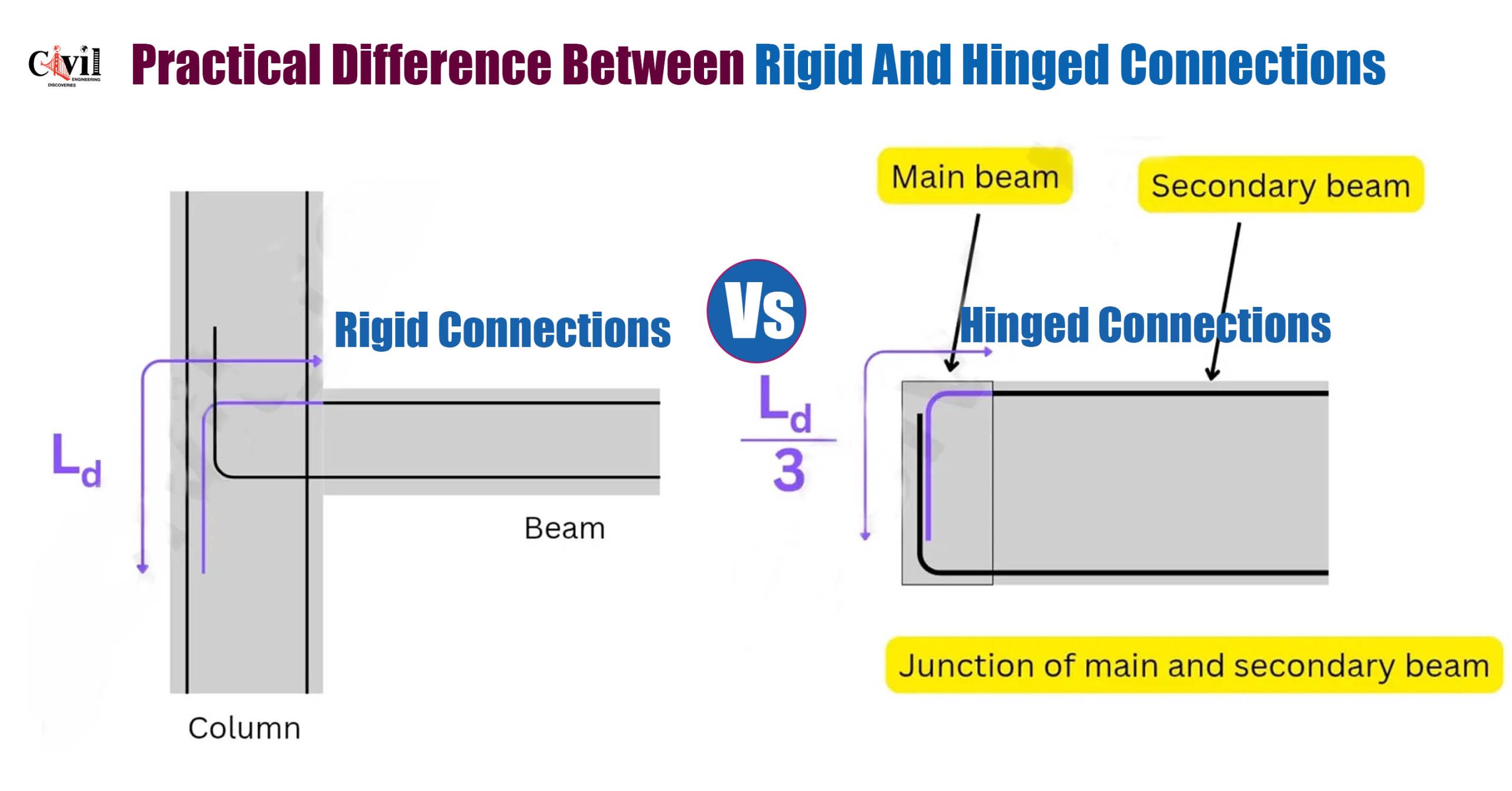

What Is a Rigid Connection?

A rigid connection, also known as a moment connection, is formed when two RCC members are joined using the reinforcement’s full development length (Ld). This means the bars are anchored completely within the connecting member, ensuring moment resistance and continuity.

Maintains structural integrity.

Transmits bending moment and shear force.

Used in beams, frames, and slabs where rigidity is required.

Visual Representation of a Rigid Joint

In a typical rigid joint, the beam-column connection uses the entire development length. This ensures the beam and column behave like a continuous unit.

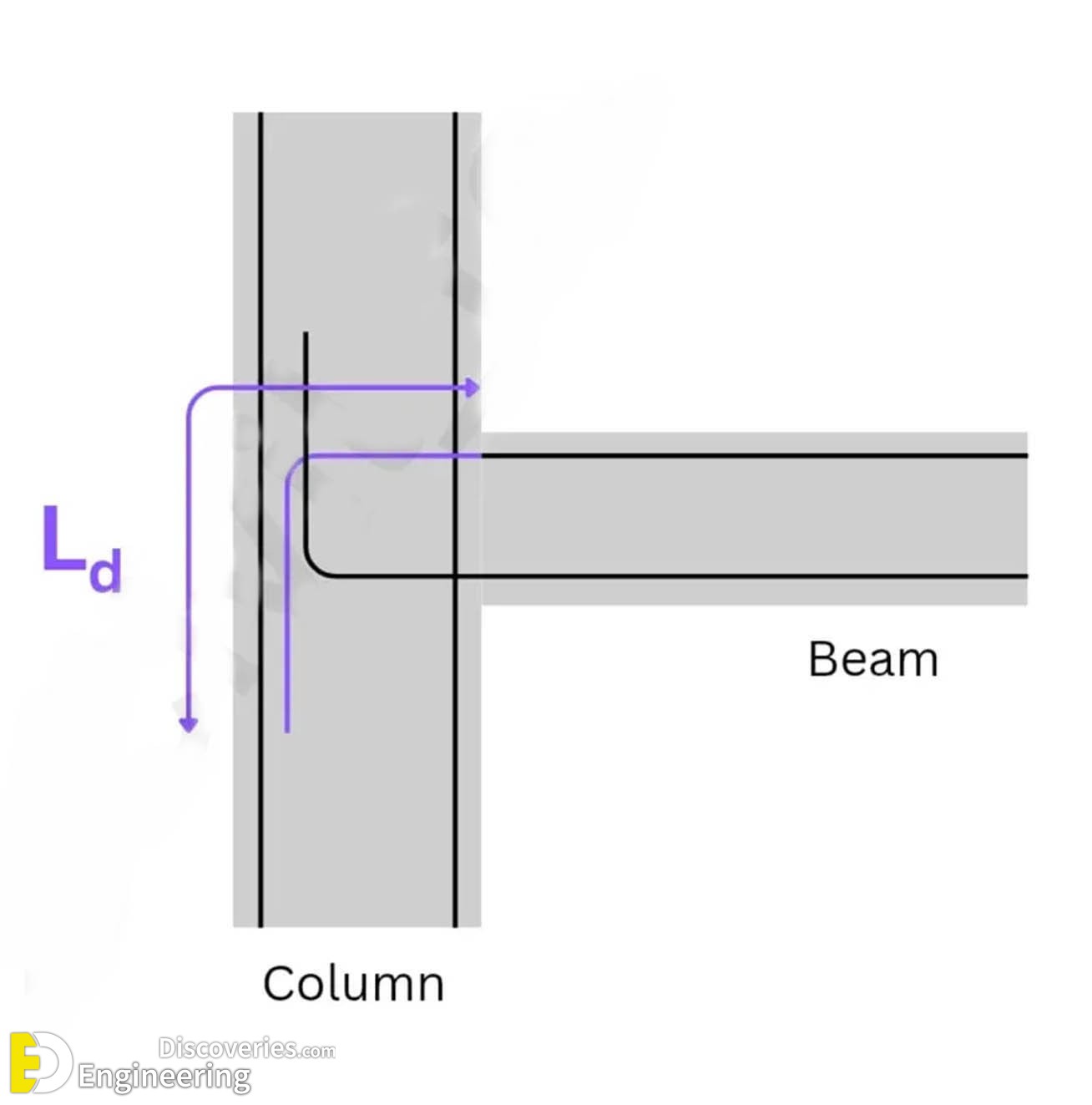

What Is a Hinged Connection?

A hinged or pinned connection allows rotation. It doesn’t resist moments effectively. To create this, engineers use only a fraction of the full development length, typically one-third of Ld.

Transfers mainly shear and axial forces.

Allows rotation without resisting bending.

Common in secondary beams or trusses.

Key Differences Between Rigid and Hinged Connections

1. Reinforcement Development Length

Rigid: Full development length used.

Hinged: Reduced length, generally Ld/3.

2. Moment Transfer Capability

Rigid: Transfers both moment and shear.

Hinged: Transfers only axial and shear forces.

3. Rotation and Flexibility

Rigid: Resists rotation.

Hinged: Allows free rotation.

4. Structural Application

Rigid: Used in moment frames and critical joints.

Hinged: Suitable for secondary members and temporary joints.

Common Practices in RCC Construction

In standard RCC construction:

Rigid joints are crucial for load-bearing frames.

Hinged joints reduce stress concentration and are economical for non-critical members.

Using Ld/3 for hinged connections is an accepted practice in many building codes.

Load Transfer Behavior

Rigid Connections:

Transfer bending moments, shear, and axial loads.

Provide better seismic performance.

Increase frame stiffness and reduce lateral deflection.

Hinged Connections:

Transfer shear and axial loads only.

Reduce the moment transfer to connected members.

Ideal where flexibility and cost reduction are needed.

When to Use Each Type?

Use rigid connections when structural stiffness and moment resistance are necessary.

Use hinged connections in areas requiring flexibility or fast construction with less reinforcement.

Click Here To See Difference Between Development Length And Lapping Length

Thanks for the information