Reinforced Cement Concrete (RCC) staircases are vital components in modern construction. They combine strength, durability, and aesthetics, making them a preferred choice for architects and engineers.

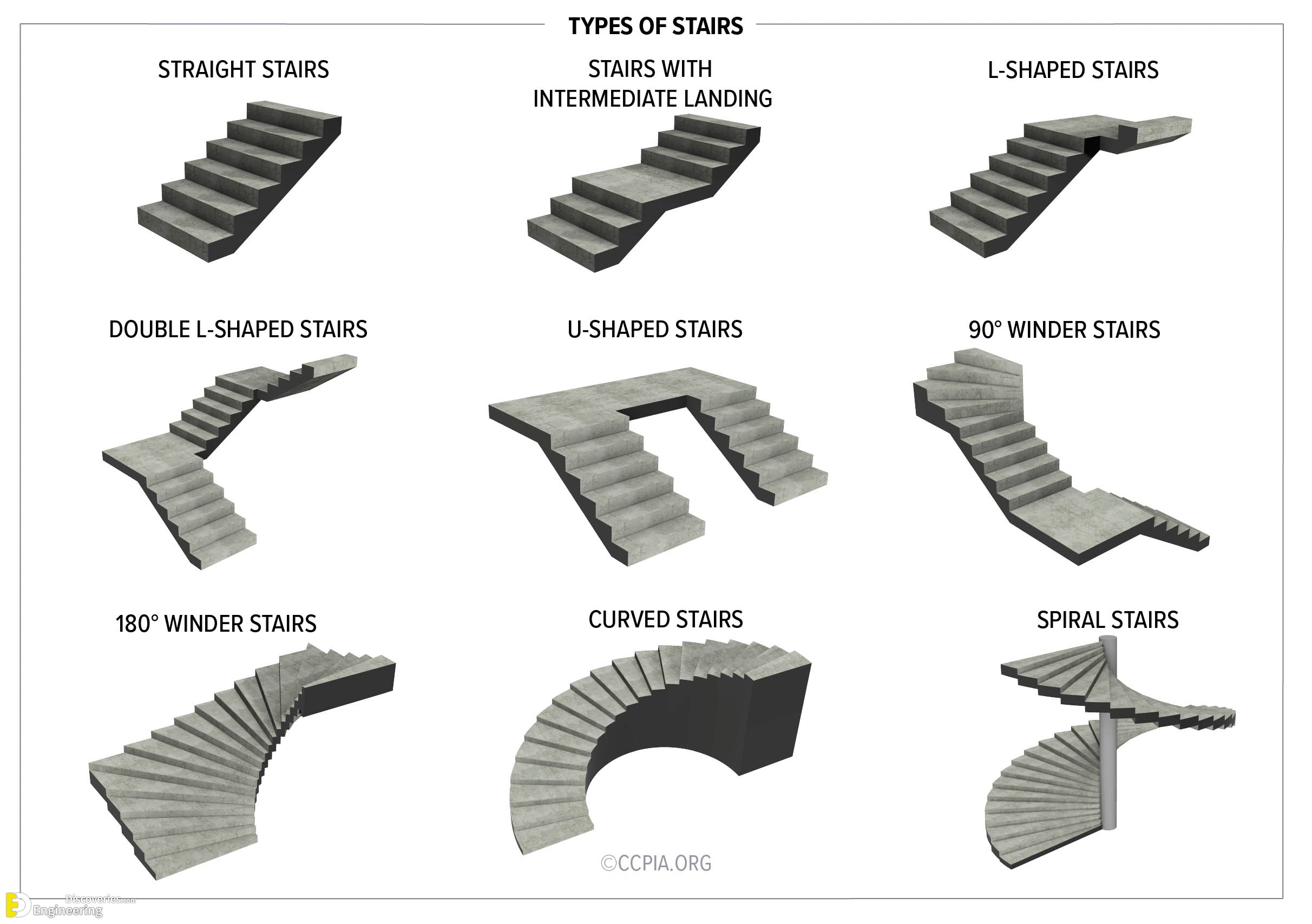

Types of RCC Staircases

Straight Staircases

These are the simplest type of RCC staircases. They follow a single linear path, making them ideal for straightforward designs.

L-Shaped Staircases

L-shaped staircases feature a 90-degree turn. They are commonly used in small spaces to optimize layout.

U-Shaped Staircases

These staircases have a 180-degree turn, making them compact and efficient for multi-story buildings.

Spiral Staircases

Spiral staircases are circular and space-saving. They are both functional and visually appealing.

Cantilever Staircases

Cantilever staircases provide a sleek, modern look. Their floating appearance adds elegance to any design.

Key Considerations in RCC Staircase Design

Load Calculation

Accurate load assessment ensures structural safety. It includes dead loads, live loads, and dynamic loads.

Material Selection

High-quality cement, aggregates, and steel reinforcement are essential. These materials guarantee durability and strength.

Dimensions and Proportions

Adhere to standard dimensions for risers, treads, and landing spaces. Proper proportions enhance functionality and safety.

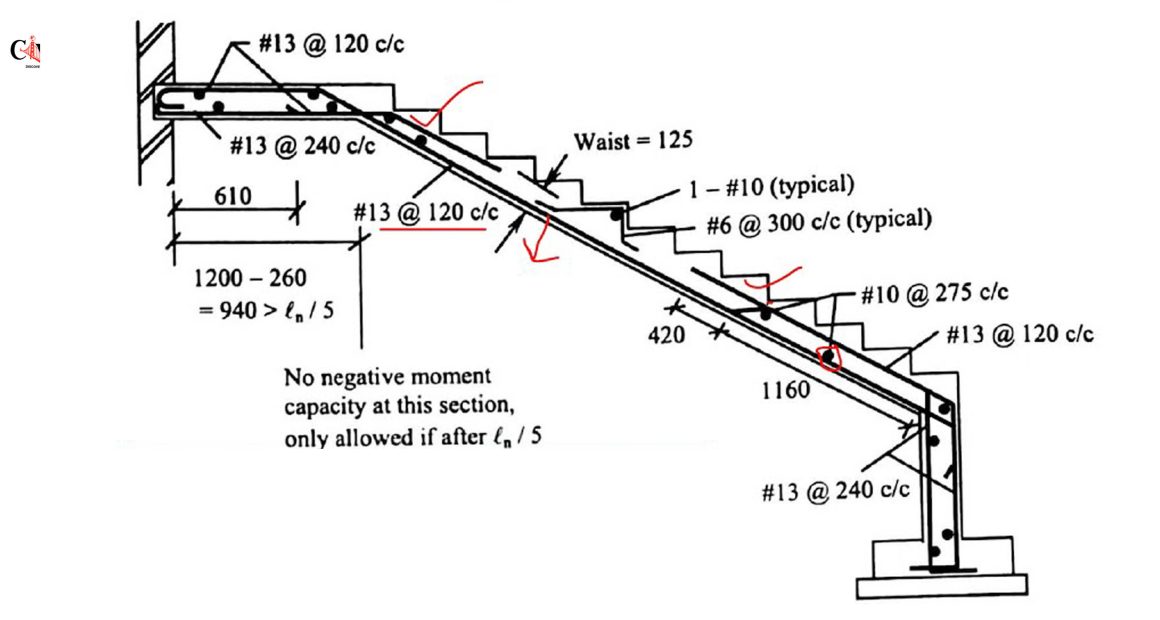

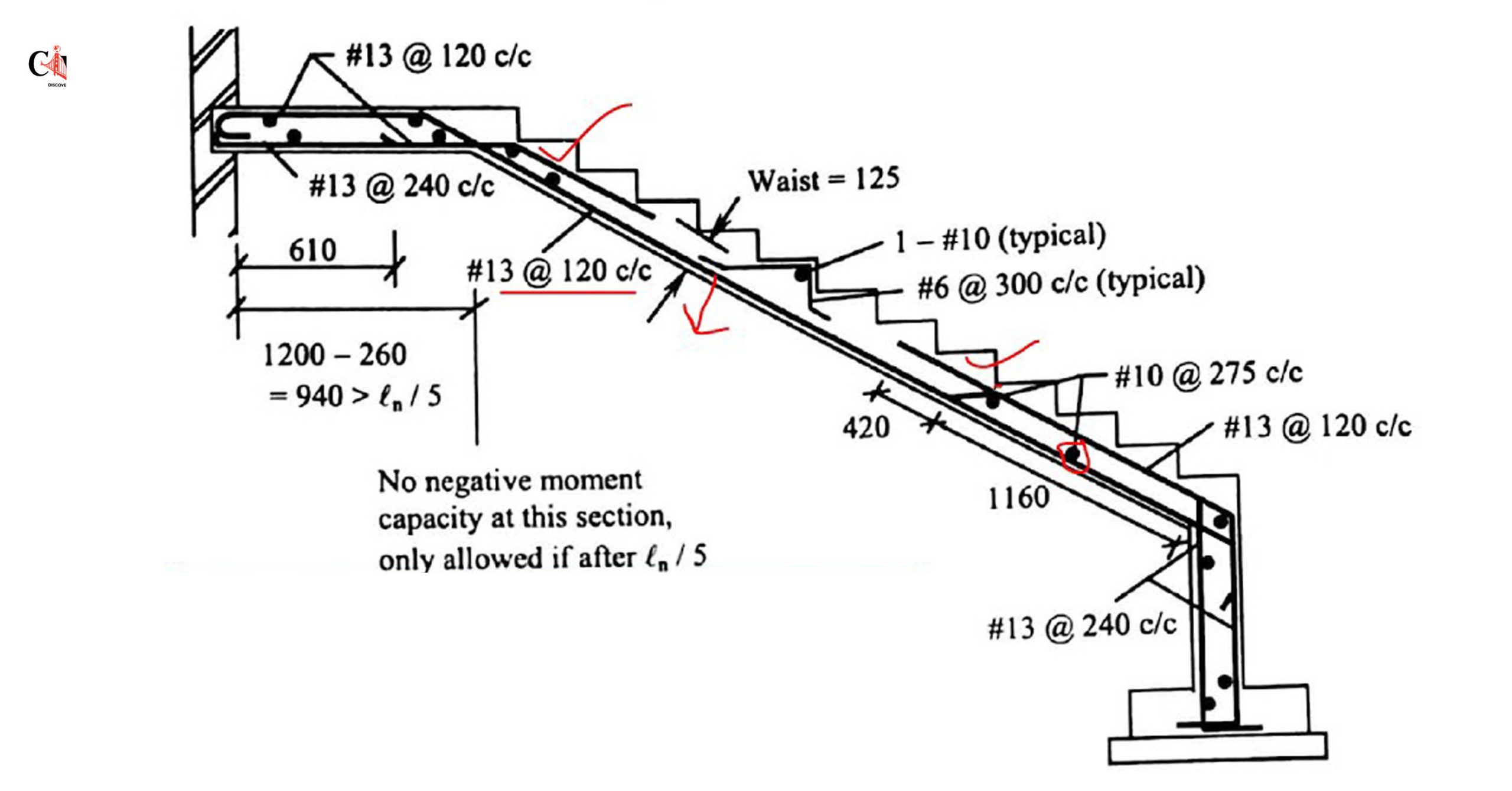

Reinforcement Detailing

Adequate reinforcement ensures stability. Use properly placed steel bars to resist tensile and shear stresses.

Advantages of RCC Staircases

- Durability: RCC staircases are resistant to wear and tear, making them long-lasting.

- Versatility: They can be customized to suit various architectural styles.

- Fire Resistance: Concrete’s inherent fire resistance enhances safety.

- Low Maintenance: Minimal upkeep is required compared to other materials.

Construction Steps for RCC Staircases

Step 1: Planning and Design

Start with detailed drawings and structural analysis. Ensure compliance with building codes.

Step 2: Formwork Installation

Construct sturdy formwork to shape the staircase. Use quality materials for precision.

Step 3: Reinforcement Placement

Position reinforcement bars according to the design. Secure them to prevent movement during concreting.

Step 4: Concrete Pouring

Pour concrete evenly and compact it to eliminate voids. Curing is essential for strength development.

Step 5: Finishing and Polishing

Once cured, apply the finishing touches. Options include polished surfaces or textured finishes for better grip.

Common Design Mistakes to Avoid

- Ignoring Load Distribution: Miscalculations can lead to structural failure.

- Improper Reinforcement: Skipping reinforcement guidelines weakens the staircase.

- Overlooking Aesthetics: Balance function with form for an appealing design.