Cantilever slabs play a vital role in structural engineering, offering extended projections without intermediate supports. To ensure these structures are both safe and durable, proper reinforcement detailing is essential. Below is a complete breakdown of reinforcement guidelines for cantilever slabs, focusing on key principles and techniques.

What Is a Cantilever Slab?

A cantilever slab is a structural element that extends beyond its support, often found in balconies, overhangs, and projections. These slabs are subjected to significant bending moments at their supports, requiring proper reinforcement to counteract tensile stresses.

Reinforcement Detailing Principles

Reinforcement in cantilever slabs serves two primary purposes:

- To resist tensile stresses at the fixed support.

- To maintain crack control and distribute loads uniformly.

Proper detailing ensures structural stability, prevents cracking, and enhances load-bearing capacity. Below are the essential guidelines.

Key Reinforcement Components in Cantilever Slabs

1. Main Tensile Reinforcement

The primary reinforcement, referred to as As, is provided at the top of the cantilever slab, near the fixed support, to resist tensile forces. The bars extend beyond the slab’s length to ensure anchorage, typically equal to Ld, the development length.

2. Distribution Steel

Distribution reinforcement is placed at right angles to the main bars. It ensures load distribution and crack resistance. Commonly, 50% of the main reinforcement area (0.5Ast) is used for the distribution of steel.

3. Anchorage and Development Length

To maintain structural integrity, the main reinforcement is anchored sufficiently into the support. The development length Ld ensures bars are adequately bonded within the slab and support, preventing slippage.

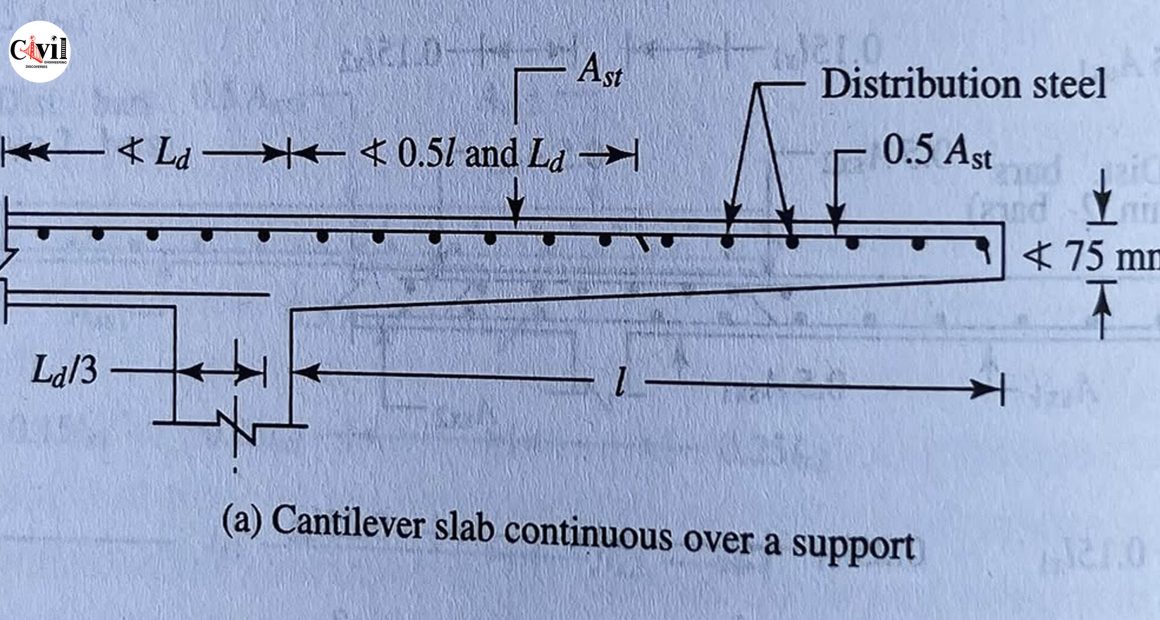

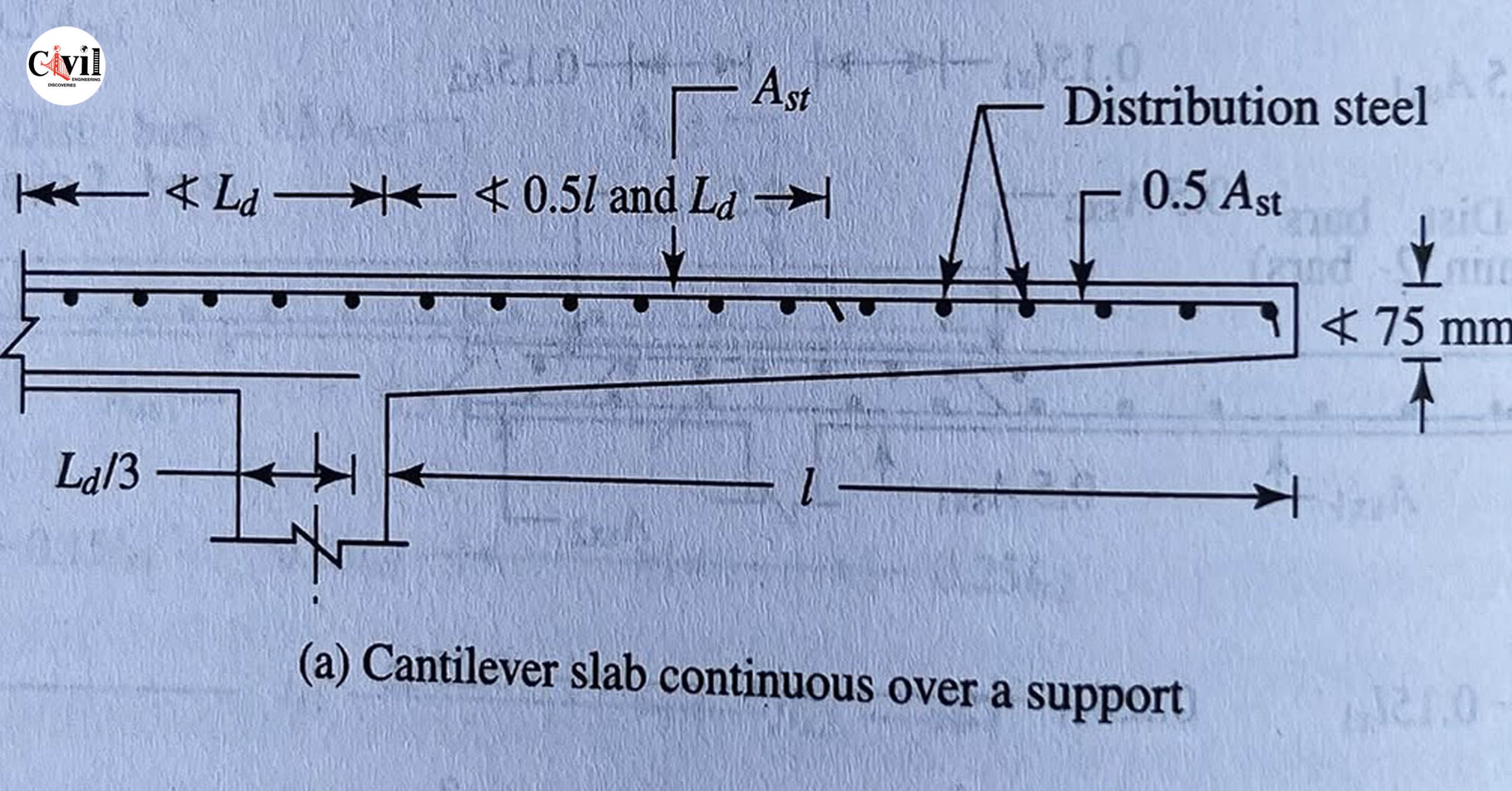

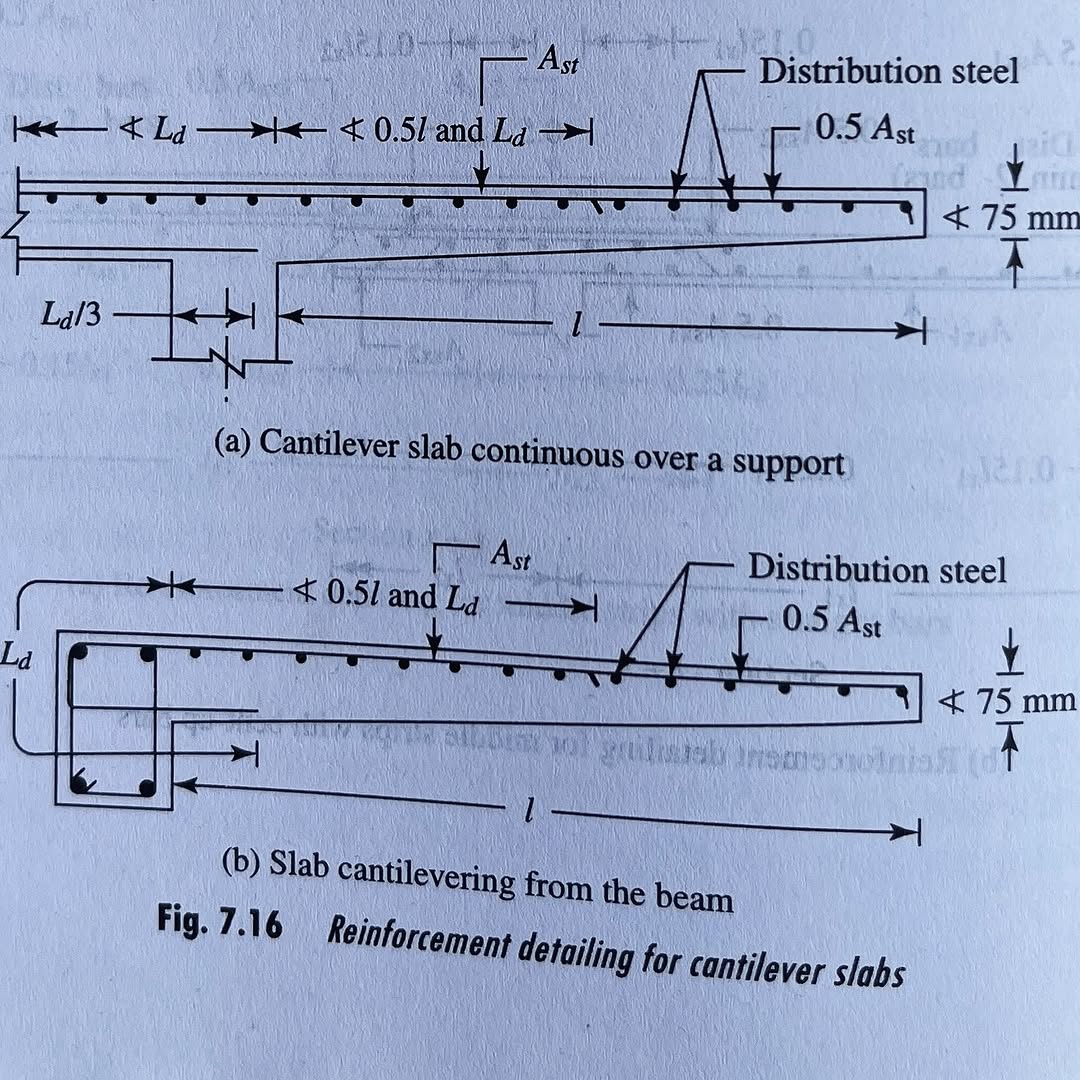

Reinforcement Detailing: Continuous Slab

When a cantilever slab is continuous over a support, the reinforcement detailing adjusts as follows:

- Main Bars: Extend from the cantilever section into the adjacent slab by 0.5 Ld development length.

- Distribution Steel: Placed perpendicular to the main bars at 50% of the main reinforcement area.

- Support Zone: Extend the bottom reinforcement into the fixed end for better load transfer.

Reinforcement Detailing: Cantilevering from Beams

For slabs cantilevering from beams:

- Main Bars: Extend from the free edge into the beam by at least Ld, ensuring sufficient anchorage.

- Stirrups in Beams: Provide closed-loop stirrups within the beam to confine the main reinforcement and resist torsion due to cantilever action.

- Bottom Steel: Reinforce the bottom of the beam to balance additional bending moments.

Guidelines for Effective Reinforcement

- Adherence to Minimum Cover: Maintain at least 75 mm of concrete cover to protect steel from corrosion.

- Spacing Rules: Follow IS code or equivalent standards for proper spacing of main and distribution reinforcement.

- Quality of Steel: Use high-strength deformed bars (HSD) for better tensile resistance.

- Concrete Mix: Ensure high-grade concrete for strength and durability, especially in cantilever zones prone to stress concentration.

Applications of Cantilever Slabs

Cantilever slabs are commonly used in:

- Balconies: Extended slabs provide aesthetic appeal and functional space.

- Overhangs in Bridges: Cantilever projections in bridges support loads effectively.

- Sunshades: Lightweight cantilever slabs create shaded areas in buildings.

Click Here To See Understanding Types Of Supports In Structural Engineering