In RCC beams, elements are designed to resist the loads that cause bending moment, shear forces and sometimes in some cases, it also causes torsion along their length. It’s a known fact that concrete is strong in compression and very weak in tension. The steel reinforcement present in the concrete is used to take up tensile stresses in reinforced concrete beams.

Mild steel bars of the round section was utilized in RCC work. But when deformed and twisted bars were introduced, the usage of mild steel bars declined. Ribs are indented on the surface of the deformed or HYSD bars which results in increasing the bond strength by at least 40% when compared to that of the mild steel bar.

Good detailing of reinforcements with proper drawings are important at the site as it helps the site engineers to place the reinforcement correctly for a good process of construction.

Terms employed in the detailing of beams

- Size and number of bars/ spacing of bars,

- Lap and curtailment of bars/bending of bars

- Development length of bars

- Clear cover to the reinforcement and

- Spacer and chair bars.

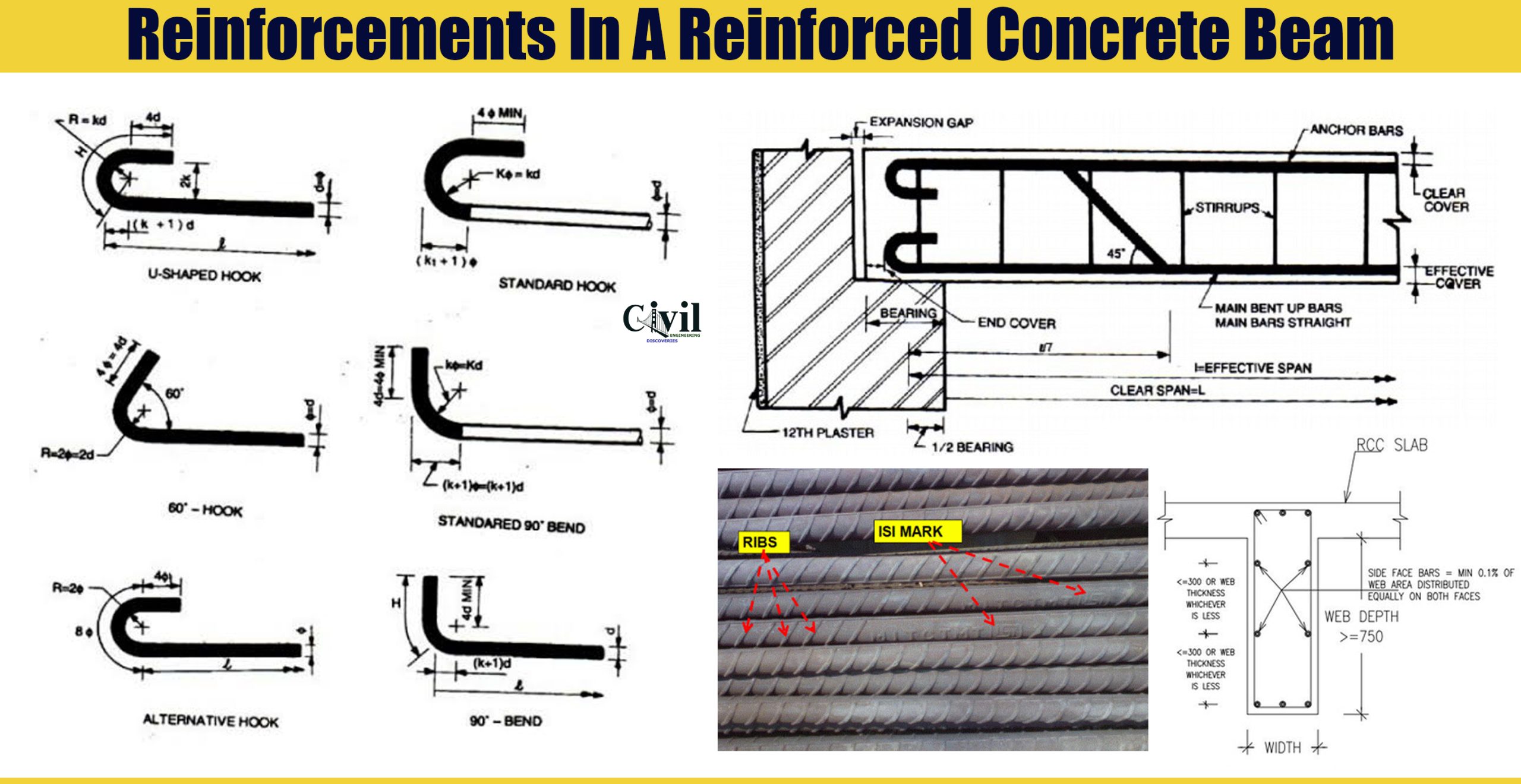

Anchorage in steel bars is usually given in the form of bends and hooks. Twisted steel bars or deformed steel bars are not provided with hooks. The anchorage value of the bend of the bar is taken as 4 times the diameter of the bar for every 450 bends subjected to a maximum of 16 times the diameter of the bar. To increase the length of bars, the bars are lapped together. Minimum lap length should be equal to development length.

The value of K mentioned in the above figure depends on the type of steel used which is given below:

- Mild steel: 2

- Cold worked steel: 4

Classification of beams according to

- Shape

- Rectangular, T-shaped, L-shaped, Circular etc.

- Support conditions

- Simply supported, Fixed, Continuous and Cantilever

- Reinforcement:

- Singly reinforced and doubly reinforced

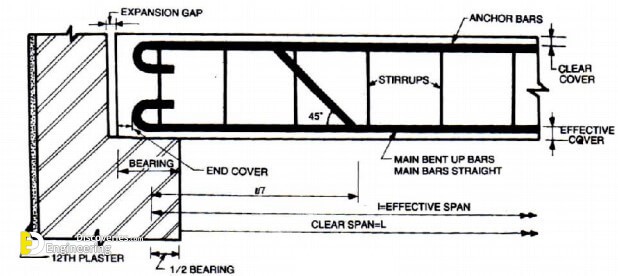

Depth of the beam is calculated based on flexural strength and to satisfy the criteria of deflection. Normally, the ratio of span to depth is kept from 10 to 15 and the depth to width ratio of rectangular is taken in the range of 1.5 to 2. Minimum cover to be provided in beams must be 25 mm or shall not be less than the larger diameter of the bar for all steel reinforcement. Nominal cover specified in IS456-2000 should be used to satisfy the durability criteria.

Reinforcements in a Beam

- Longitudinal reinforcement at tension and compression face in single or multiple rows are provided. Minimum of two 12 mm diameter bars are required to be provided in tension.

- Shear reinforcements which are provided to resist shear, are placed in the form of vertical stirrups and or bent up longitudinal bars.

- Side face reinforcement is required in the web of the beam when the depth of the web in a beam exceeds 750 mm.

Bars of size 6,8,10,12,16,20,25,32,50 mm are available in market.

Representation of Bars in Drawings

- Main bars are shown by a thick single line.

- Hanger bars are indicated by medium thick lines.