Aim

To determine the particle size distribution of fine and coarse aggregates by sieving as per IS: 2386 (Part I) – 1963.

Principle

By passing the sample downward through a series of standard sieves, each of decreasing size openings, the aggregates are separated into several groups, each of which contains aggregates in a particular size range.

Apparatus

1- A set of IS Sieves of sizes – 80mm, 63mm, 50mm, 40mm, 31.5mm, 25mm, 20mm, 16mm, 12.5mm, 10mm, 6.3mm, 4.75mm, 3.35mm, 2.36mm, 1.18mm, 600μm, 300μm, 150μm and 75μm

2- Balance or scale with an accuracy to measure 0.1

Sample

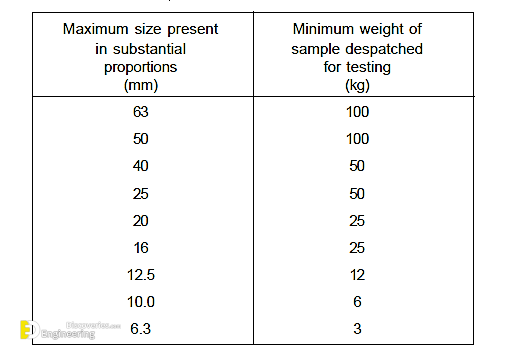

The weight of sample available should not be less than the weight given below:-

The sample for sieving should be prepared from the larger sample either by quartering or by means of a sample divider.

Procedure

1- The test sample is dried to a constant weight at a temperature of 110 + or – 5 oC and weighed.

2- The sample is sieved by using a set of IS Sieves.

3- On completion of sieving, the material on each sieve is weighed.

4- Cumulative weight passing through each sieve is calculated as a percentage of the total sample weight.

5- Fineness modulus is obtained by adding a cumulative percentage of aggregates retained on each sieve and dividing the sum by 100.

Result

The results should be calculated and reported as:

1- the cumulative percentage by weight of the total sample

2- the percentage by weight of the total sample passing through one sieve and retained on the next smaller sieve, to the nearest 0.1 percent.

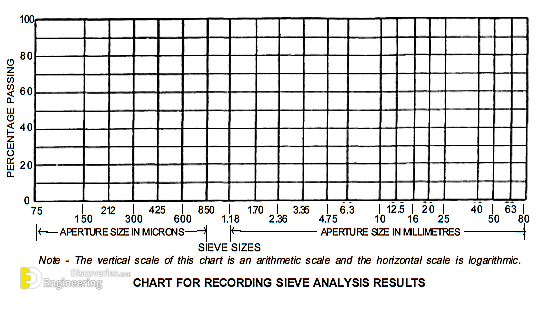

The results of the sieve analysis may be recorded graphically on a semi-log graph with a particle size as abscissa (log scale) and the percentage smaller than the specified diameter as ordinate.

A sample chart is provided below

For more information watch this video