In structural engineering, staircase reinforcement is pivotal in ensuring the safety, durability, and structural integrity of any building. Whether for residential, commercial, or industrial construction, stairs are more than just a means of movement — they are critical load-bearing components that must be carefully designed and reinforced.

Understanding staircase reinforcement is essential for architects, civil engineers, contractors, and even homeowners who aim for precision and long-lasting construction. This comprehensive guide covers all aspects of staircase reinforcement, from types of rebars used to placement details, best practices, and structural optimization.

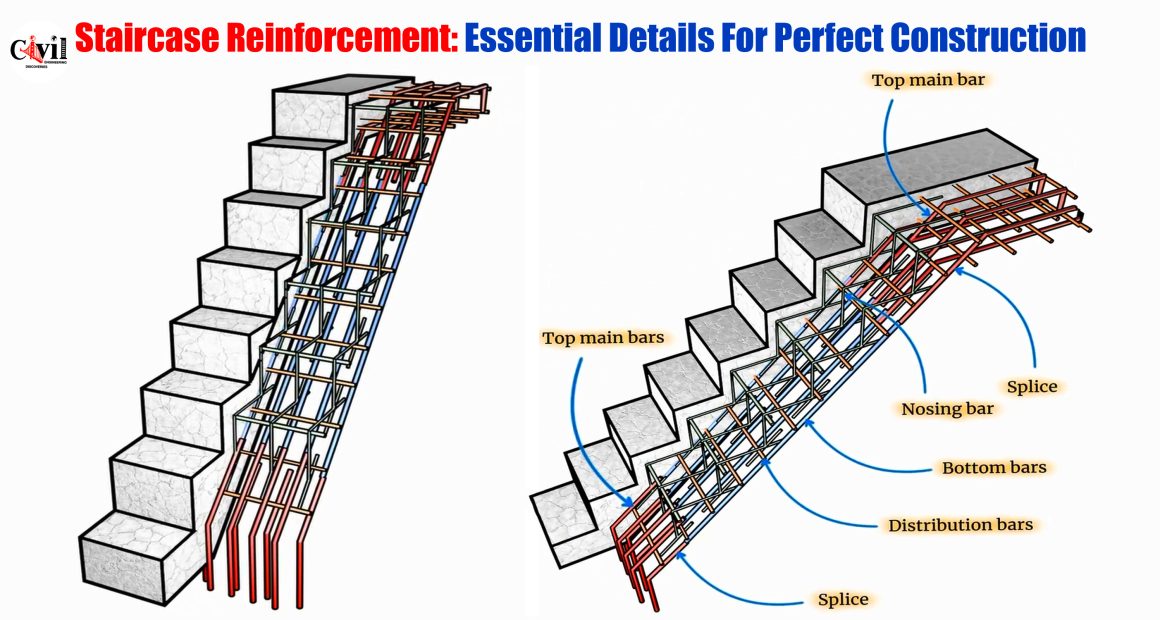

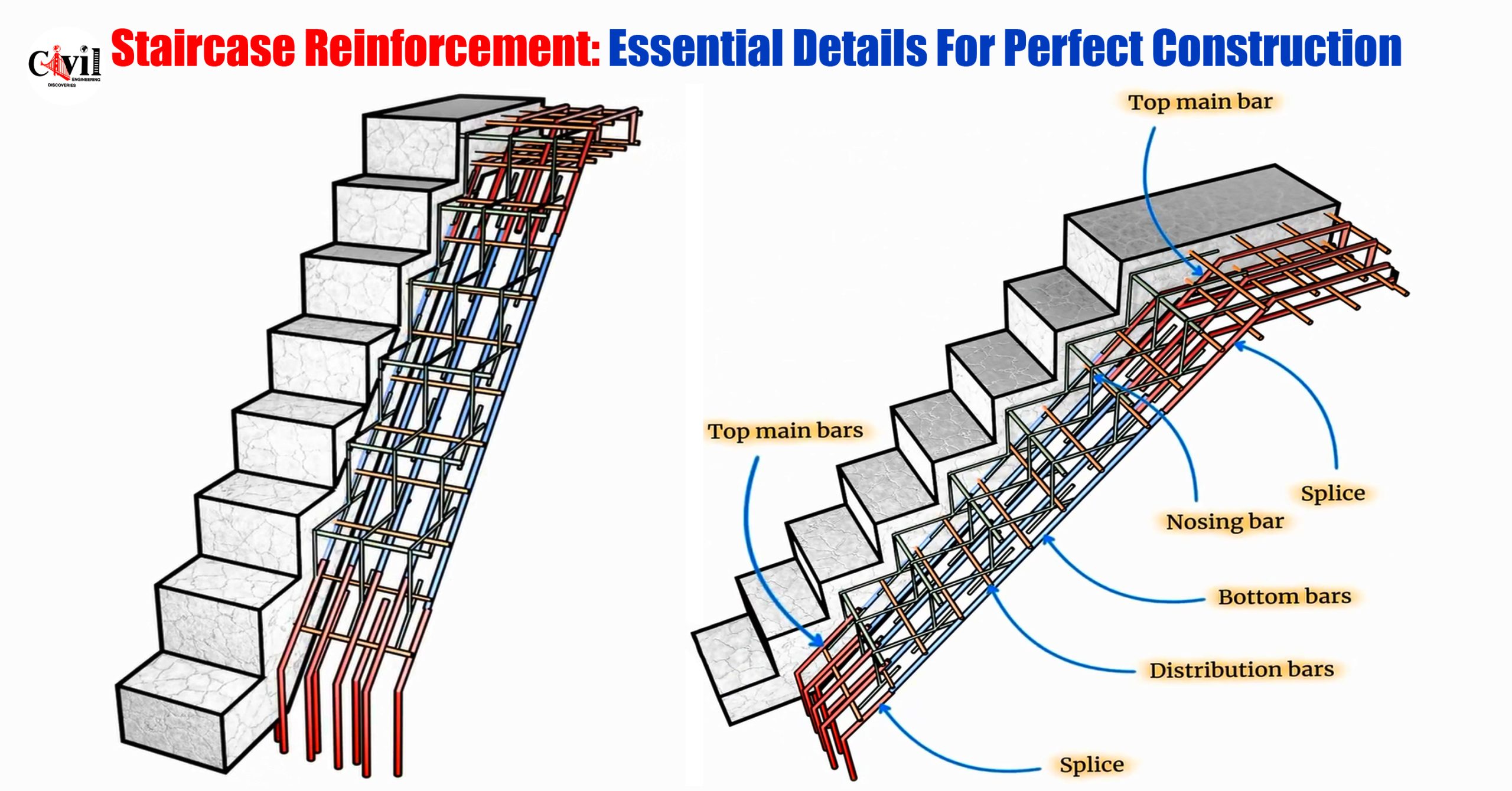

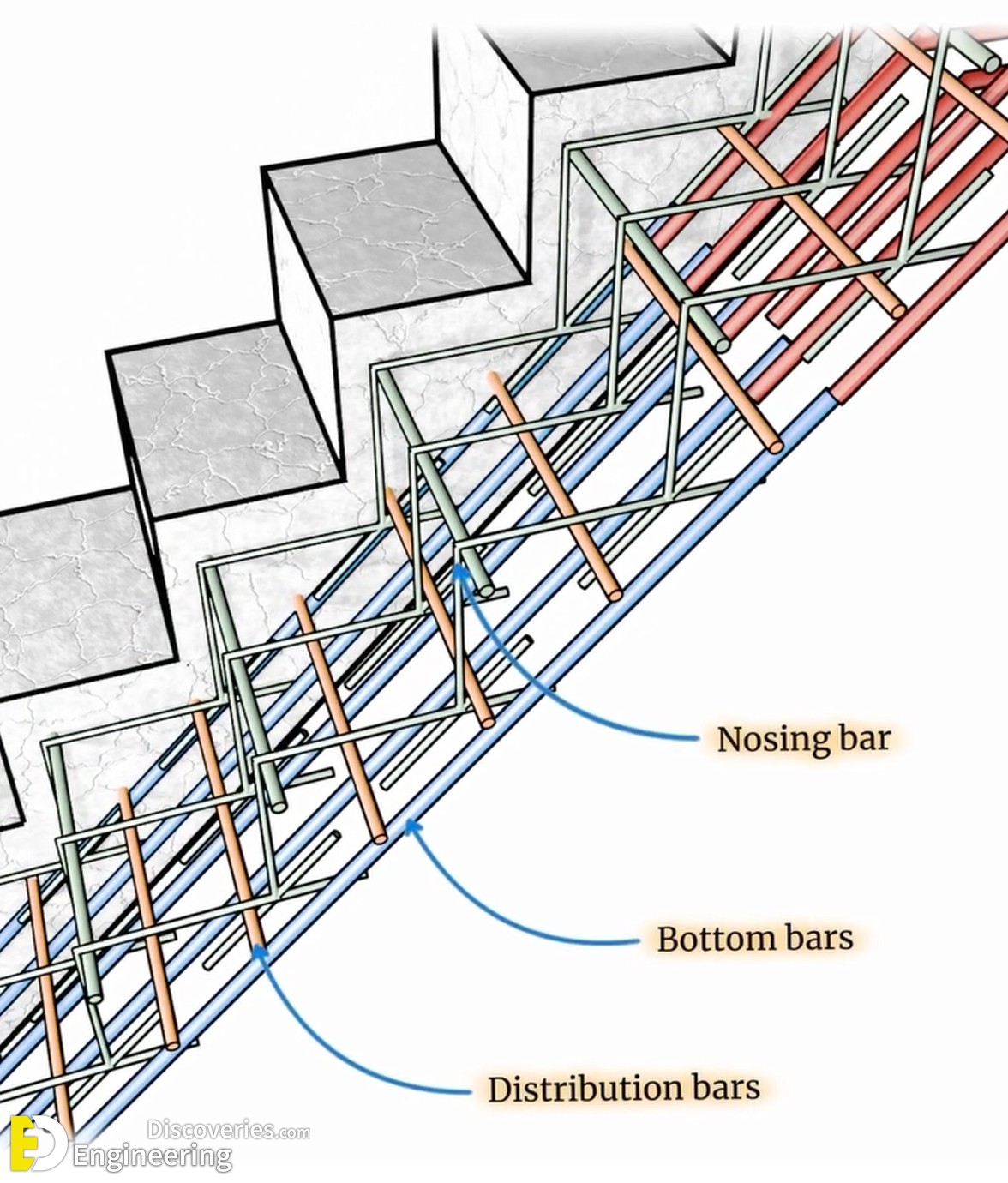

Components of Staircase Reinforcement

A typical staircase reinforcement includes several crucial elements. These components work in unison to support both static and dynamic loads.

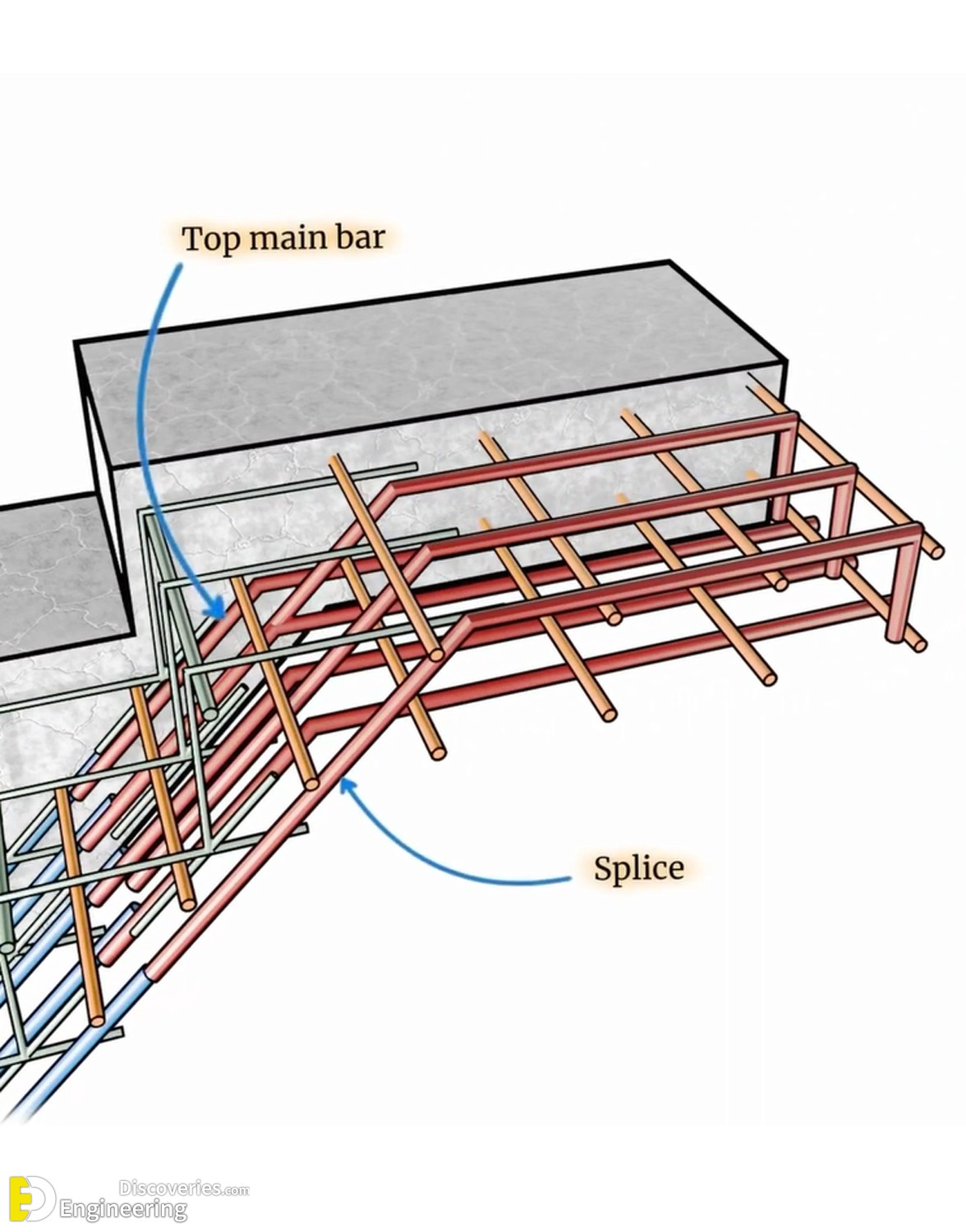

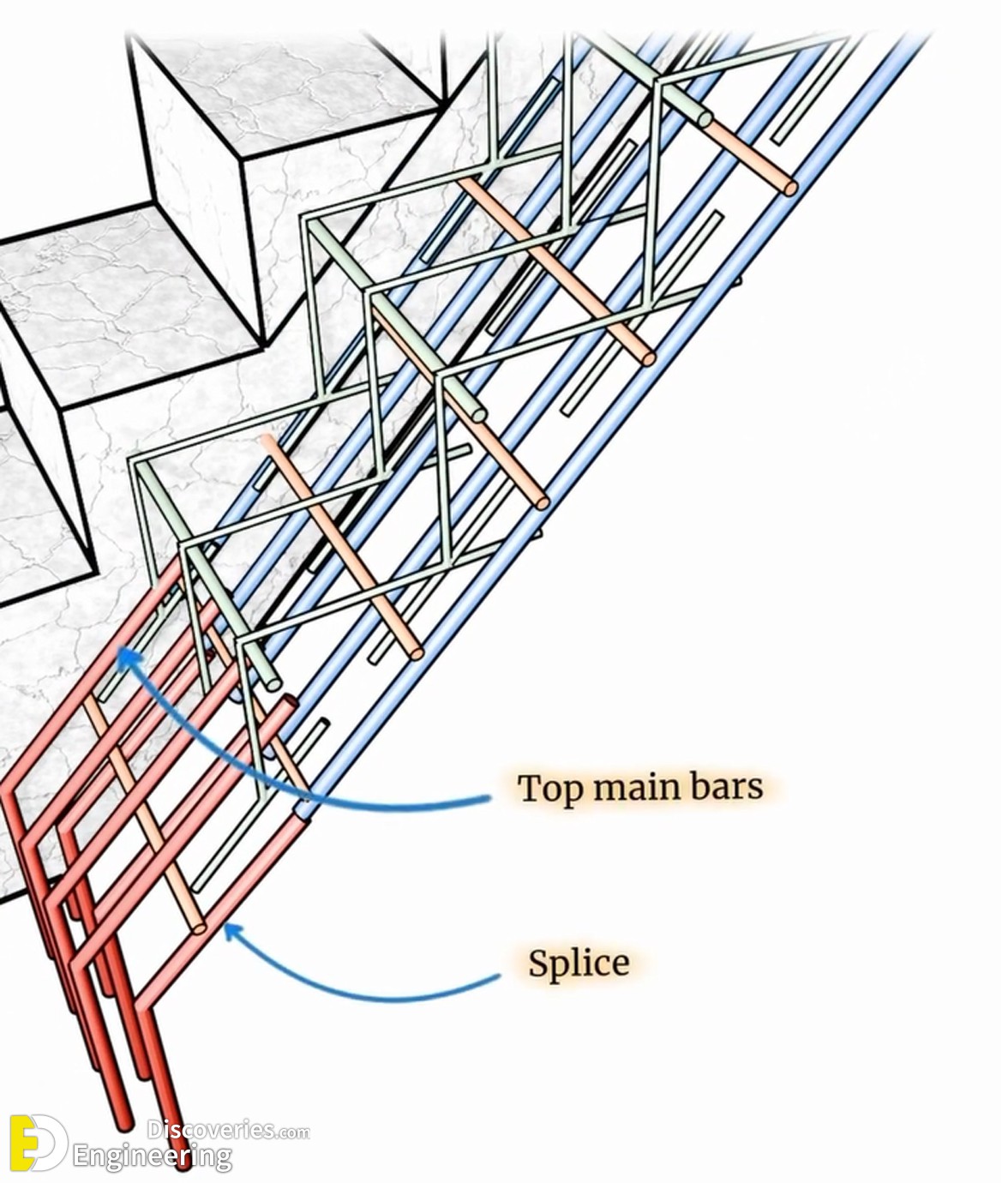

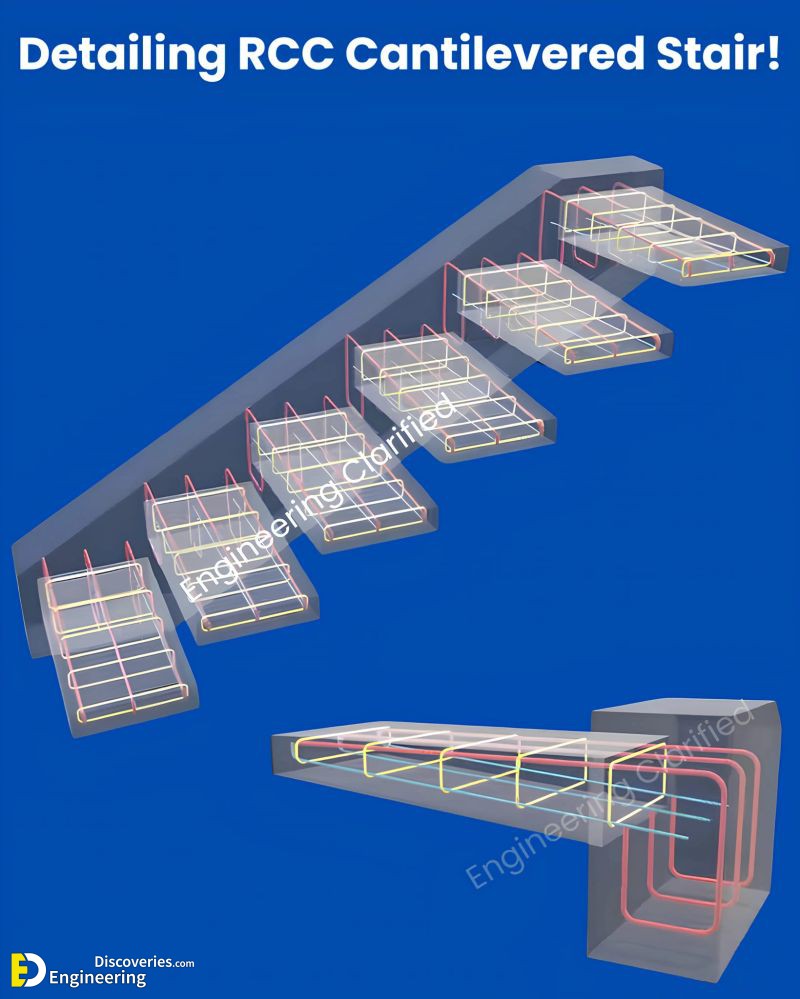

Top Main Bars

Top main bars are placed along the top portion of the inclined slab. They resist tensile stresses, especially in cantilevered staircases, and provide necessary strength to the upper layer of the structure.

Splice Locations

Splice bars are used when a single reinforcement bar is not long enough to span the entire staircase length. Proper splicing with sufficient overlap ensures load transfer and bar continuity. Splicing must be done as per structural codes to maintain safety and reliability.

Bottom Bars

These bottom reinforcement bars are vital for resisting tension forces at the bottom face of the stair slab. They extend along the flight length and provide bending resistance where needed the most.

Distribution Bars

Distribution bars, placed perpendicular to the main bars, help to distribute loads uniformly and prevent cracking due to temperature changes and shrinkage. These bars are especially important in ensuring the uniform spread of loads and reinforcement stability.

Nosing Bars

Nosing bars are provided at the tread-riser junction. These bars enhance the strength of the stair edge, where stress concentration is usually higher due to foot traffic. They ensure that the staircase maintains its form and doesn’t develop cracks at the edges.

Types of Staircases and Reinforcement Approaches

Different stair configurations require tailored reinforcement detailing. Here are the most common types and their reinforcement requirements:

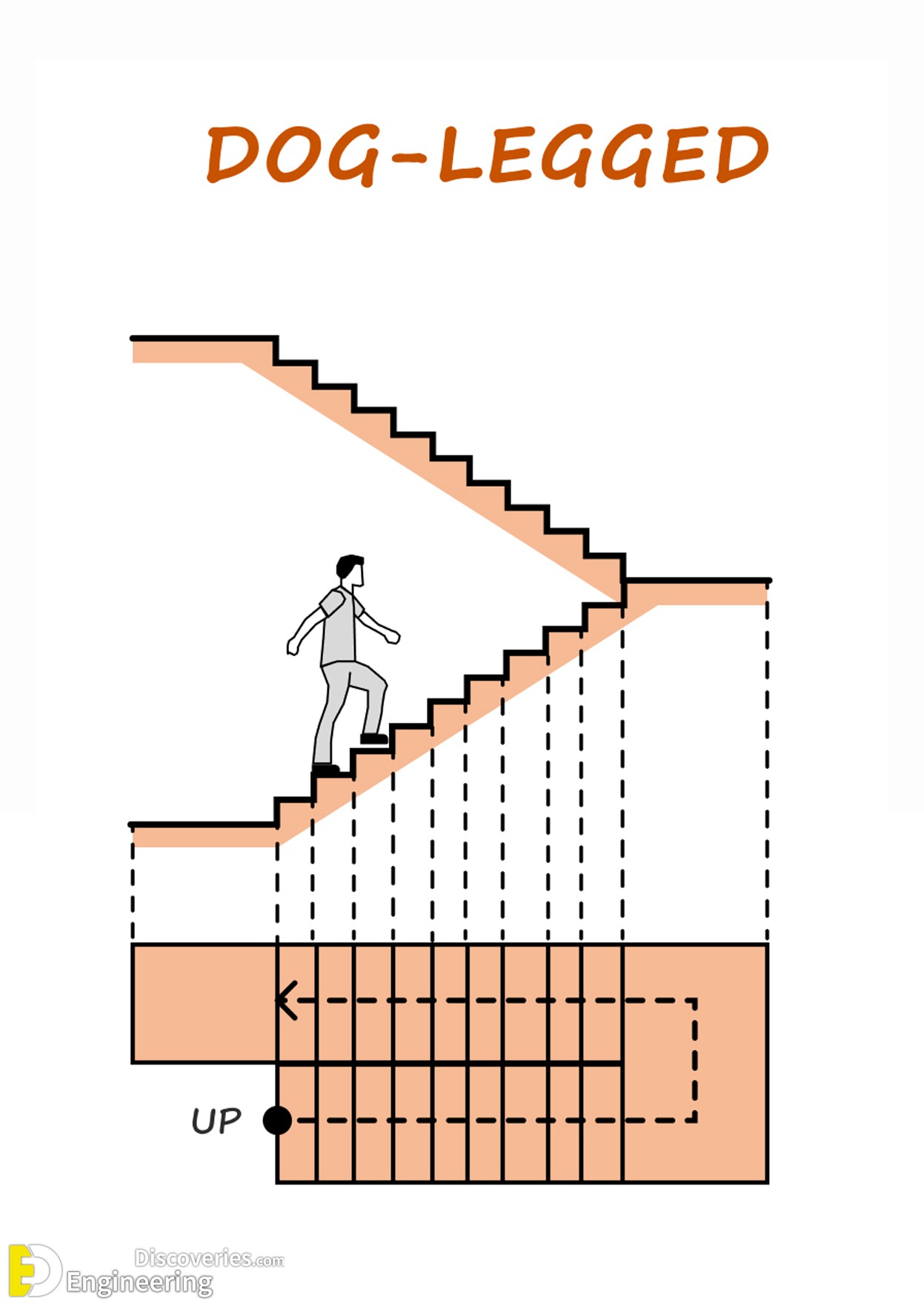

1. Dog-Legged Staircase

This type involves two flights of stairs in opposite directions with a landing in between. The reinforcement bars are continuous over the landing, and proper anchorage is crucial. Extra attention is paid to the junction between flight and landing to avoid stress concentration.

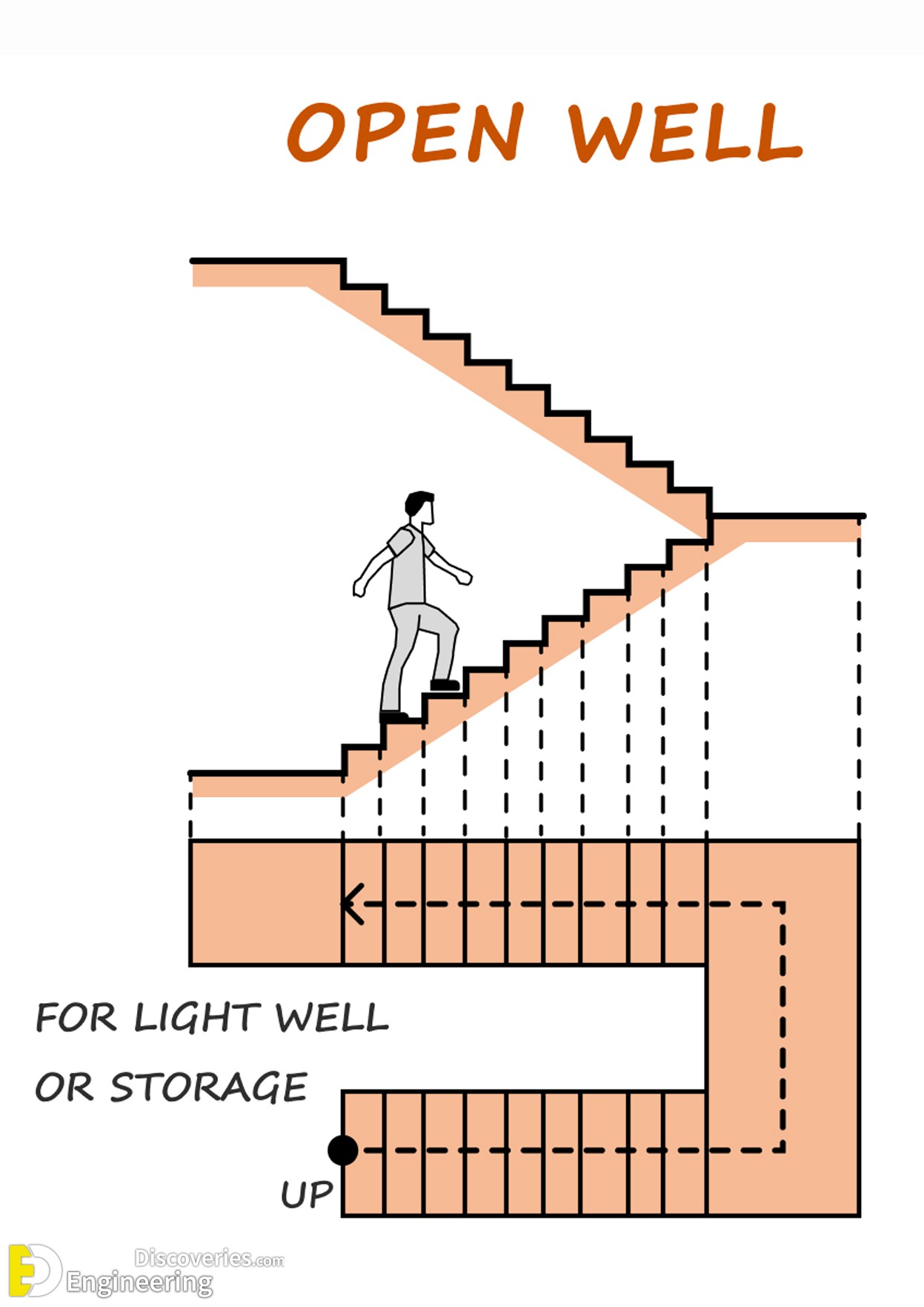

2. Open-Well Staircase

With an open space between two flights, these staircases demand strong longitudinal reinforcement and solid support at both ends. Reinforcement is designed to resist bending moments induced by unsupported spans.

3. Cantilever Staircase

These stairs project from one end only. Thus, top main bars are more critical here as they resist the tension caused by bending. Cantilever stairs demand a more complex reinforcement layout and often involve high-grade steel.

Staircase Reinforcement Design Tips

Optimizing staircase reinforcement is vital for construction economy and safety. Below are key design tips:

1. Follow Standard Reinforcement Ratios

Maintain appropriate steel-to-concrete ratios as specified in IS 456:2000 or equivalent codes. Over-reinforcing can lead to congestion, while under-reinforcing compromises safety.

2. Proper Bar Spacing

Ensure adequate spacing between the reinforcement bars to allow for proper concrete flow and compaction. Use spacers and chairs to hold bars in the correct position during casting.

3. Adequate Anchorage and Development Length

Bar anchorage is crucial for load transfer. Development length must comply with code requirements to prevent slippage under stress.

4. Use L-shaped Bars at Tread-Riser Joints

L-shaped or bent bars are typically used at the junction of the tread and riser to enhance torsional resistance and crack control.

5. Avoid Abrupt Curves and Kinks

Smooth bends ensure uniform stress distribution and prevent stress concentration, which could lead to early failure in concrete structures.

Reinforcement Detailing Best Practices

Clear Cover

Maintain a minimum cover of 25 mm for staircases exposed to weather and 20 mm for internal stairs. This prevents corrosion and ensures fire resistance.

Lap Lengths

When splicing bars, follow standard lap lengths—typically 50 times the bar diameter for tension zones.

Use of Support Bars

Include support bars under the distribution bars to prevent sagging. Proper bar chairs or concrete blocks help hold the mesh structure in place.

Avoid Rebar Congestion

Dense rebar can hinder proper concrete placement. Plan staggered placement and use bundling only where structurally feasible.

Precast vs. Cast-In-Place Considerations

In precast staircases, reinforcement is placed within factory-controlled environments, ensuring consistency. However, cast-in-place stairs require on-site accuracy, and bar placement must be continuously checked for alignment and anchorage.

Staircase Reinforcement Calculation Example

A simple example for a dog-legged staircase:

Width of stair = 1.2 m

Rise = 150 mm, Tread = 300 mm

Flight length = 15 steps × 300 mm = 4.5 m

Slab thickness = 150 mm

Reinforcement Design:

Main bars: 12 mm diameter @ 150 mm c/c

Distribution bars: 8 mm diameter @ 200 mm c/c

Nosing bar: 10 mm diameter bent at riser-tread junction

Splice length: 600 mm (for 12 mm dia bars)

Concrete grade: M25, Steel: Fe 500

All reinforcement bars must be tied using 18-gauge binding wire. Check concrete placement and curing to eliminate honeycombs and ensure bond development.

Common Errors in Staircase Reinforcement

Avoid these frequent mistakes:

Insufficient anchorage leading to bar slippage.

Improper bar placement causing cracking and sagging.

Neglecting nosing reinforcement, leading to tread edge failure.

Incorrect splicing without the required lap length.

Ignoring load path, especially in cantilevered staircases.

Importance of Supervision and Inspection

Continuous supervision during bar bending, placement, and concrete pouring ensures that design specifications are adhered to. Site engineers and supervisors must check for:

Correct bar size and spacing

Clear cover blocks in place

Adequate supports and bar overlaps

Placement sequence as per bar bending schedule

Click Here To See Accurate Concrete Volume Calculation For Staircase Construction by Imperial System