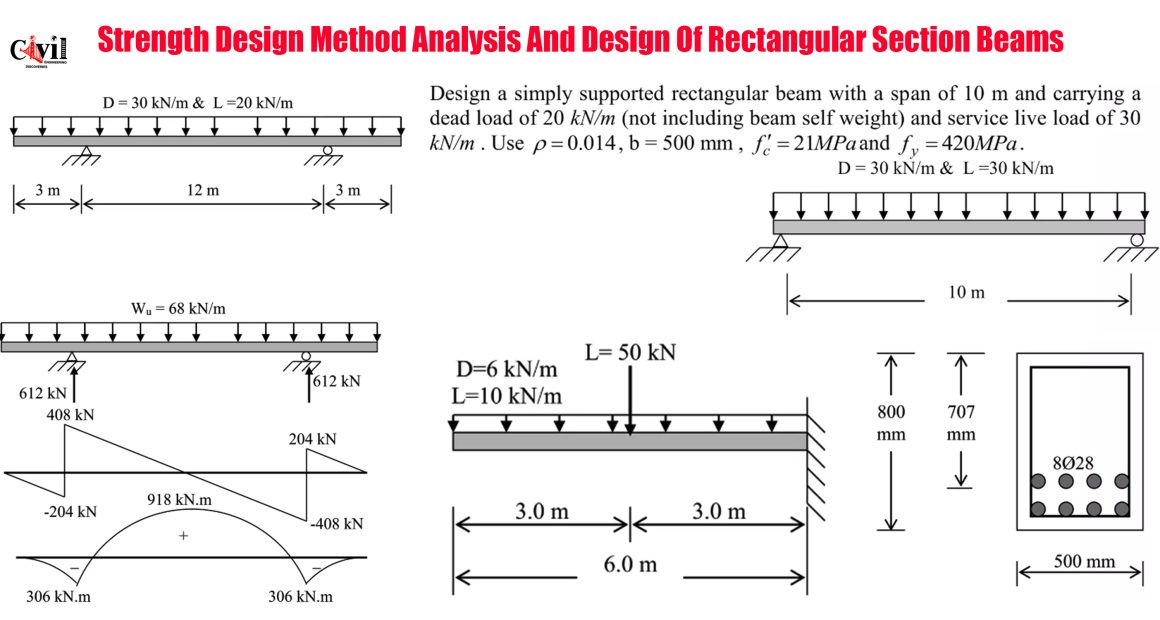

The Strength Design Method is fundamental in modern structural engineering, ensuring that beams withstand dead and live loads efficiently. Let’s analyze a supported rectangular beam with a 10m span, subjected to a 20 kN/m dead load (excluding self-weight) and a 30 kN/m service live load. How do we ensure it meets safety and serviceability criteria?

Material Selection & Reinforcement Strategy

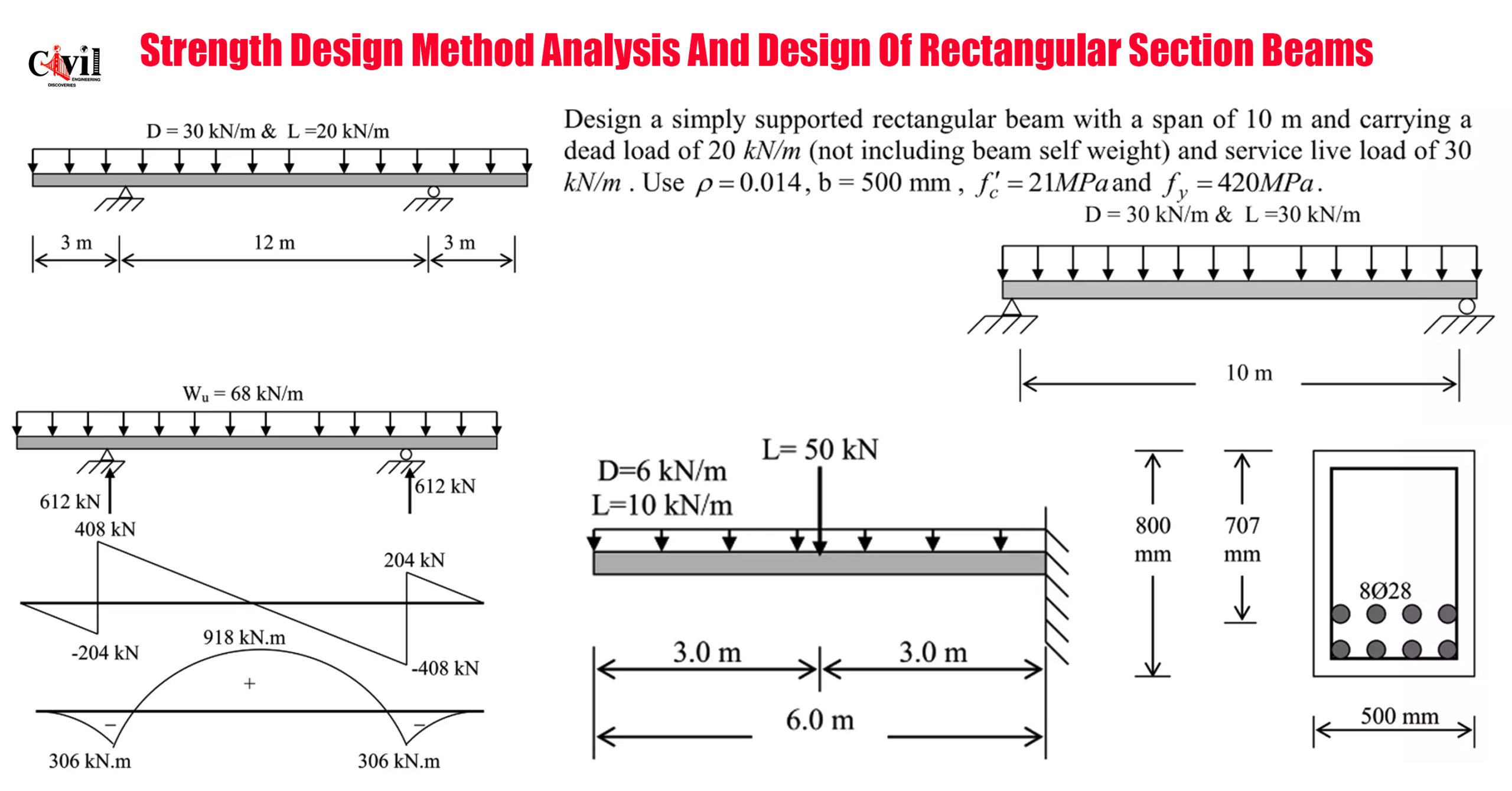

Choosing the right materials is crucial. In this case, we use concrete with fc = 21 MPa and steel reinforcement with fy = 420 MPa. A reinforcement ratio of p = 0.014 ensures optimal strength while maintaining a ductile failure mode. The 500mm beam width provides structural stability, but determining the required depth involves moment calculations.

Structural Behavior & Load Resistance

To ensure an efficient beam design, we evaluate the bending moment capacity against the applied loads. The combination of dead and live loads results in a total uniform load, generating the maximum bending moment at mid-span. The position of the neutral axis must remain within the permissible range, allowing concrete to resist compression while steel bars handle tension forces.

Code Compliance & Design Optimization

Meeting serviceability requirements is as important as ensuring ultimate strength. We conduct deflection checks, crack control assessments, and durability evaluations to finalize the beam’s dimensions. The goal is to achieve a balance between strength, economy, and sustainability—a key principle in modern structural design.

By following the Strength Design Method, engineers can design beams that are not only safe and efficient but also cost-effective and durable, ensuring long-term performance in real-world applications.

Click Here To Download PDF File

Click Here To See Calculating Steel Replacement In Columns On-Site