Introduction

When it comes to designing earthquake-resistant structures, the choice of reinforcement in concrete elements plays a critical role in safeguarding buildings. One of the most crucial aspects in construction is the use of seismic hooks, specifically the 135-degree seismic hooks or stirrups. These hooks are essential in ensuring that buildings can withstand the forces of an earthquake, maintaining the structural integrity of columns and beams. In contrast, using 90-degree hooks, which are common in traditional designs, may lead to severe structural damage when seismic forces strike.

What Are Seismic Hooks and Stirrups?

Seismic hooks and stirrups are steel reinforcements used in the construction of concrete beams, columns, and other load-bearing elements. These steel rods provide extra strength and support to the concrete by holding it in place and resisting cracking or breakage under stress. In areas prone to earthquakes, the use of seismic hooks becomes even more critical as they help absorb and distribute the forces generated by seismic activity.

Why Are 135-Degree Hooks Better Than 90-Degree Hooks?

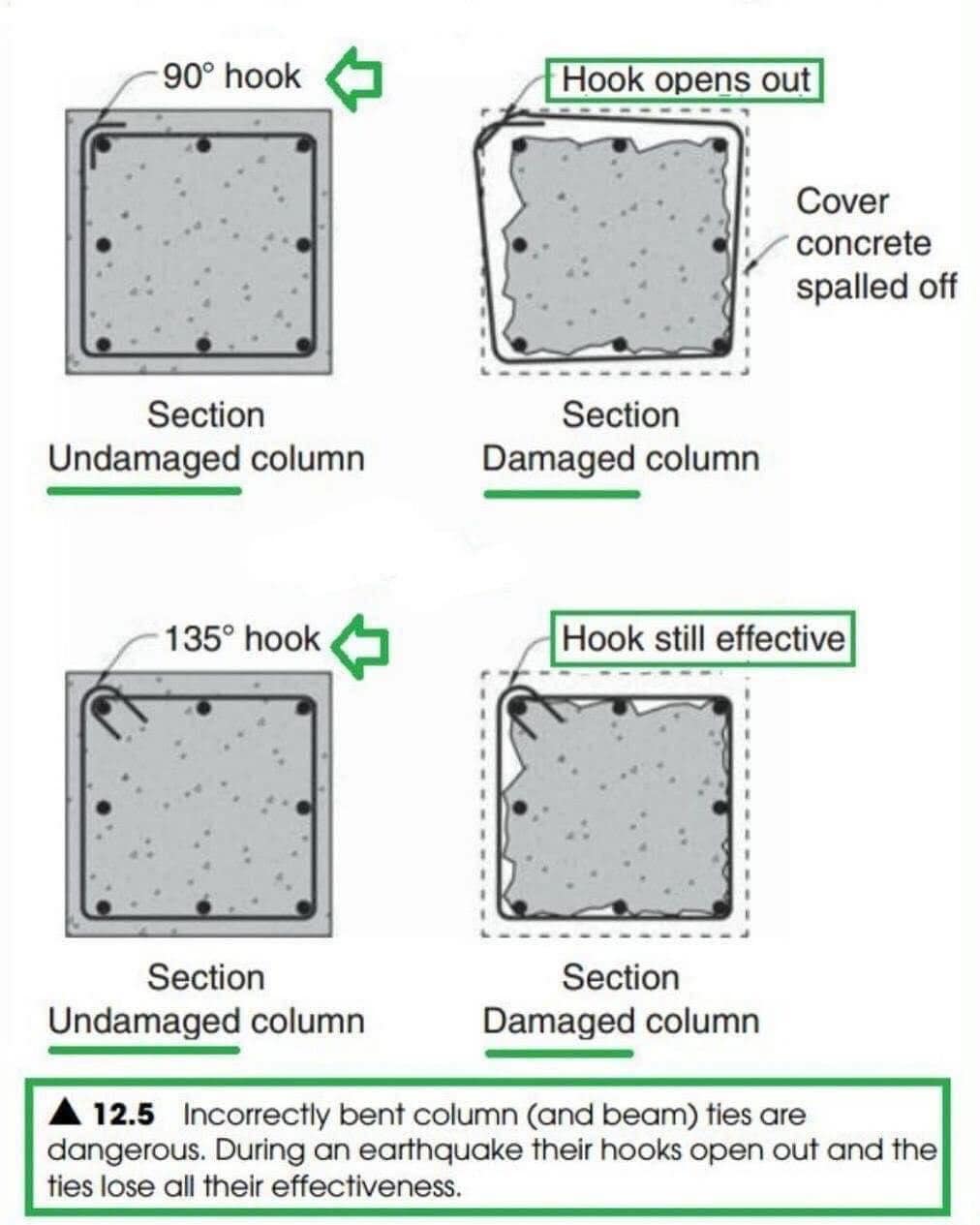

A key difference between 135-degree and 90-degree seismic hooks lies in their ability to hold the concrete securely during seismic events. The 135-degree hook provides a much tighter and stronger grip, significantly enhancing the bond between the steel reinforcement and the concrete.

Here are some key reasons why 135-degree hooks are superior:

- Stronger anchorage: The 135-degree hook creates a more secure loop, anchoring the steel rod tightly into the concrete. This prevents the reinforcement from slipping or pulling out under tension.

- Greater structural flexibility: In an earthquake, buildings must be able to absorb energy without breaking apart. The 135-degree hook ensures that the steel reinforcement remains intact and flexible, allowing the structure to move without collapsing.

- Improved load distribution: 135-degree hooks ensure that stress and forces are evenly distributed across the structural element. This means less stress is concentrated in one area, reducing the likelihood of structural failure.

In contrast, 90-degree hooks provide less effective anchorage and are more prone to slipping or failure under stress. This is why engineers and builders strongly recommend using 135-degree hooks, particularly in seismic zones.

Real-Life Consequences of Not Using 135-Degree Hooks

Structures that do not use 135-degree seismic hooks are more vulnerable to collapse or severe damage during earthquakes. When the ground shakes, forces are transmitted to the building’s foundation and skeleton. If 90-degree hooks are used, these forces may cause the steel reinforcements to slip or become displaced. As a result, cracks and deformations may occur, ultimately leading to the failure of load-bearing columns and beams. This can be catastrophic, not only for the building but also for the safety of its occupants.

On the other hand, buildings that incorporate 135-degree seismic hooks are much better equipped to handle seismic forces. These structures are more likely to survive earthquakes with minimal damage, preserving the safety of residents and reducing costly repairs.

Code Compliance and Best Practices

In many countries, building codes have been updated to mandate the use of 135-degree hooks in seismic zones. This is a recognition of their superior performance in earthquake-resistant design. Following these codes ensures that buildings are constructed to the highest safety standards, protecting lives and investments in the event of an earthquake.

Best practices for the installation of 135-degree hooks include:

- Ensuring that the hooks are properly bent and embedded within the concrete

- Adequately spacing stirrups to provide uniform support

- Regularly inspecting reinforcement during construction to ensure compliance with building codes

Click Here To See The Right Way And The Wrong Way To Place Concrete In Column

good knowledge