Pouring concrete into columns is a critical step in the construction process, especially when the height of the column exceeds 3 meters. Proper technique ensures that the structural integrity of the column is maintained, and the concrete is uniformly placed without segregation or voids. When this process is done incorrectly, it can lead to weak spots in the structure and potentially hazardous failures.

In this article, we will discuss the right way and the wrong way to place concrete in columns, focusing on height management, avoiding segregation, and ensuring proper compaction.

Understanding Column Height and Its Challenges

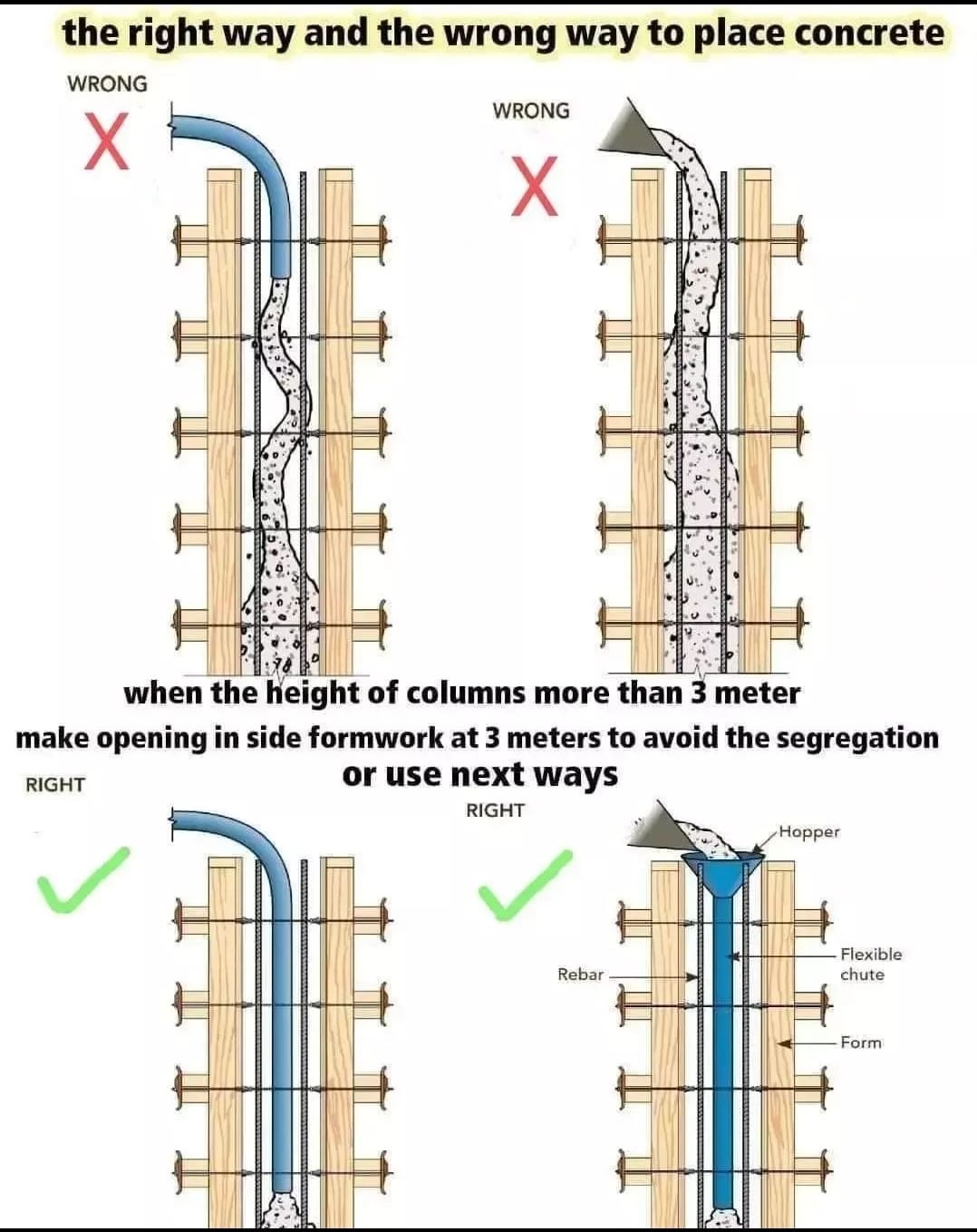

When the height of a column exceeds 3 meters, specific challenges arise in the placement of concrete. Segregation—the separation of coarse aggregates from the cement paste—becomes a major concern, especially when concrete falls from a considerable height. In taller columns, the impact of the concrete hitting the bottom can cause the mix to separate, leading to weak spots in the structure.

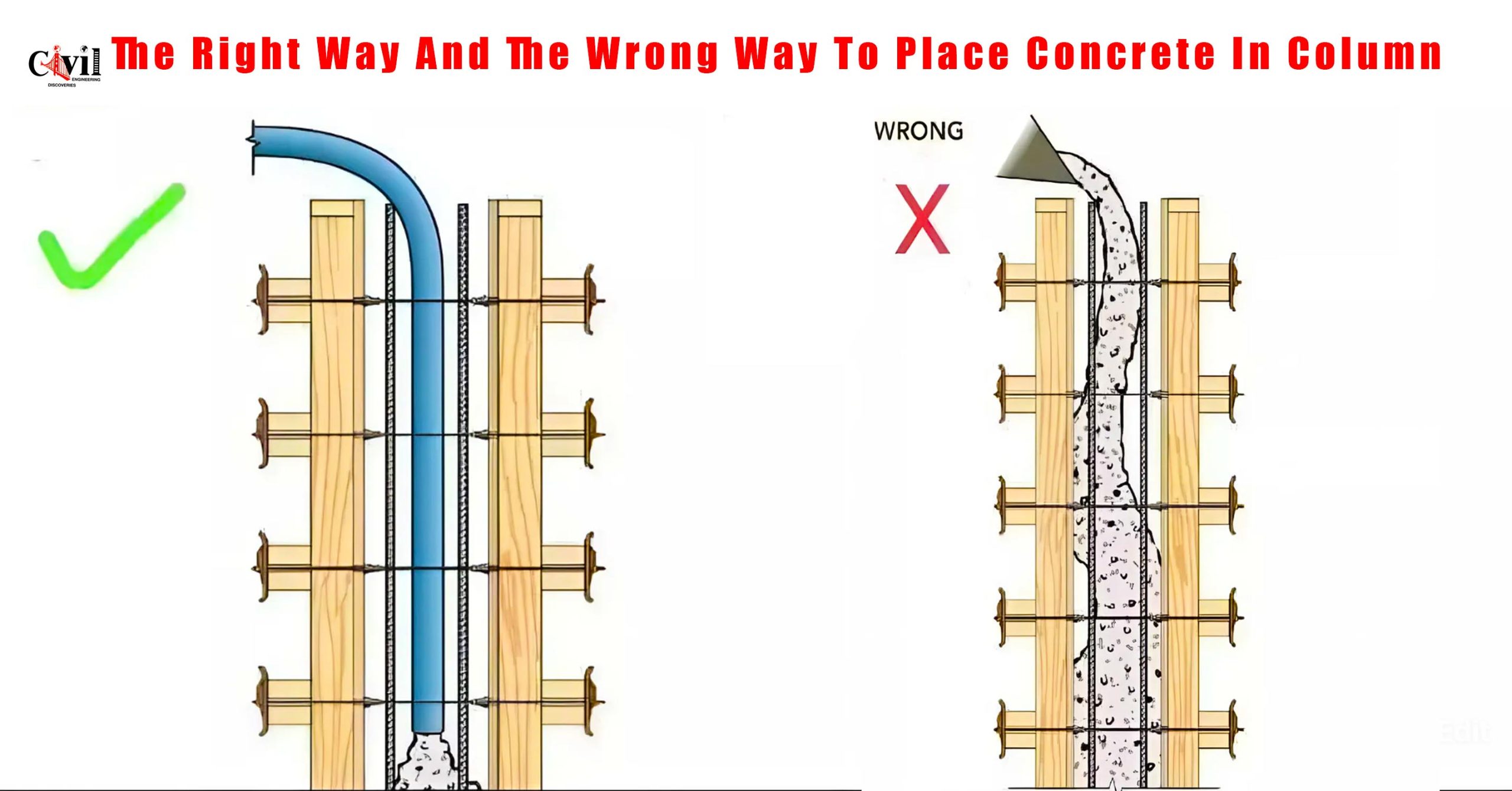

The wrong way to place concrete in such a scenario is to pour it from the top without creating an opening or using specialized equipment. This results in a higher risk of segregation and an uneven distribution of aggregates, which compromises the strength of the column.

The right way is to make an opening in the formwork at intervals, typically at 3-meter heights, or to use methods that ensure even distribution and compaction of the concrete. These techniques prevent segregation and allow for the concrete to settle properly.

The Right Way to Place Concrete in Tall Columns

1. Using Openings in the Formwork

When the column height is more than 3 meters, it’s advisable to make openings in the side of the formwork at every 3-meter interval. These openings allow the concrete to be placed in smaller, more controlled sections rather than being dropped from a great height.

Key Benefits:

- Reduced segregation: By pouring concrete in sections, the mix remains more uniform, and the risk of separation between aggregates and cement paste is minimized.

- Better compaction: It’s easier to ensure that each layer of concrete is properly compacted, avoiding voids or air pockets that could weaken the column.

- Improved workability: Workers can more easily manage the concrete as it is poured in smaller portions.

2. Using a Tremie Pipe or Chute

Another highly effective method for placing concrete in tall columns is to use a tremie pipe or chute. A tremie pipe is a long, flexible tube that allows concrete to be poured from the top while controlling the flow and preventing free fall. This method ensures that the concrete is placed smoothly, reducing the risk of segregation.

Advantages of Using a Tremie Pipe:

- Controlled flow: The tremie pipe allows for continuous placement of concrete without exposing it to air, which helps prevent segregation.

- No direct impact: The pipe’s design ensures that the concrete doesn’t hit the bottom of the formwork with excessive force, reducing the chance of separation.

- Flexibility: Tremie pipes can be adjusted in length, making them ideal for columns of various heights.

3. Vibrating the Concrete

Compaction is a vital part of placing concrete, especially in tall columns. After pouring concrete, it must be vibrated to remove any trapped air and ensure the mix is dense and solid. Vibrating the concrete can be done manually or with mechanical vibrators, but it is essential to ensure uniform compaction across the entire height of the column.

Why Vibrating is Crucial:

- Eliminates air pockets: Proper compaction removes air voids that can weaken the structure and reduce its load-bearing capacity.

- Ensures uniformity: Vibration helps to distribute the aggregates evenly throughout the mix, ensuring that the entire column is of consistent strength.

4. Layer-by-Layer Placement

Pouring concrete in layers is another recommended method for columns taller than 3 meters. Instead of pouring the entire volume at once, you can place the concrete in layers of about 300-500 mm at a time. This method allows for better control over the placement and ensures that each layer is properly compacted before the next one is added.

Advantages of Layered Placement:

- Improved compaction: Each layer can be vibrated individually, ensuring thorough compaction and preventing air voids.

- Better control: Placing concrete in layers gives workers more control over the distribution and reduces the risk of segregation.

The Wrong Way to Place Concrete in a Column

1. Free-falling concrete From Height

Allowing concrete to free-fall from a height of more than 3 meters is a major mistake. When concrete falls freely over such a long distance, it is subjected to segregation, where the heavier aggregates separate from the cement paste. This results in a column that has weak spots, reduced strength, and potential for failure.

Consequences of Free-Falling Concrete:

- Segregation: The heavier aggregates will settle at the bottom, while the cement paste remains at the top, leading to an uneven mix.

- Voids and honeycombing: Without proper compaction, free-falling concrete is likely to form air pockets or voids, weakening the structure.

- Uneven surface: The finished column may have a rough surface due to poor placement and segregation.

2. Skipping the Vibration Process

Another common mistake in concrete placement is failing to vibrate the concrete adequately. Without vibration, air trapped within the mix cannot escape, and the concrete will not achieve its maximum density.

Results of Poor Compaction:

- Air pockets: These can severely weaken the structure, reducing load-bearing capacity and possible failure under stress.

- Cracking: Improperly compacted concrete is more prone to cracking, especially under heavy loads or environmental stress.

- Lower durability: Without proper compaction, the concrete will be more susceptible to damage from weathering and other environmental factors.

3. Pouring Concrete Too Quickly

Pouring concrete into a tall column too quickly can lead to several problems. When concrete is placed too fast, it doesn’t have time to settle and compact properly. This can result in honeycombing—a condition where voids and gaps form in the concrete, significantly weakening the structure.

Dangers of Rapid Pouring:

- Honeycombing can leave gaps in the column, reducing its structural integrity.

- Segregation: Rapid pouring increases the likelihood of segregation, leading to an uneven mix and weak spots.

- Inconsistent density: The concrete may not be compacted evenly, leading to a column that lacks uniform strength.

Click Here To See Failure In RCC Beam: Flexure Failure Vs. Shear Failure