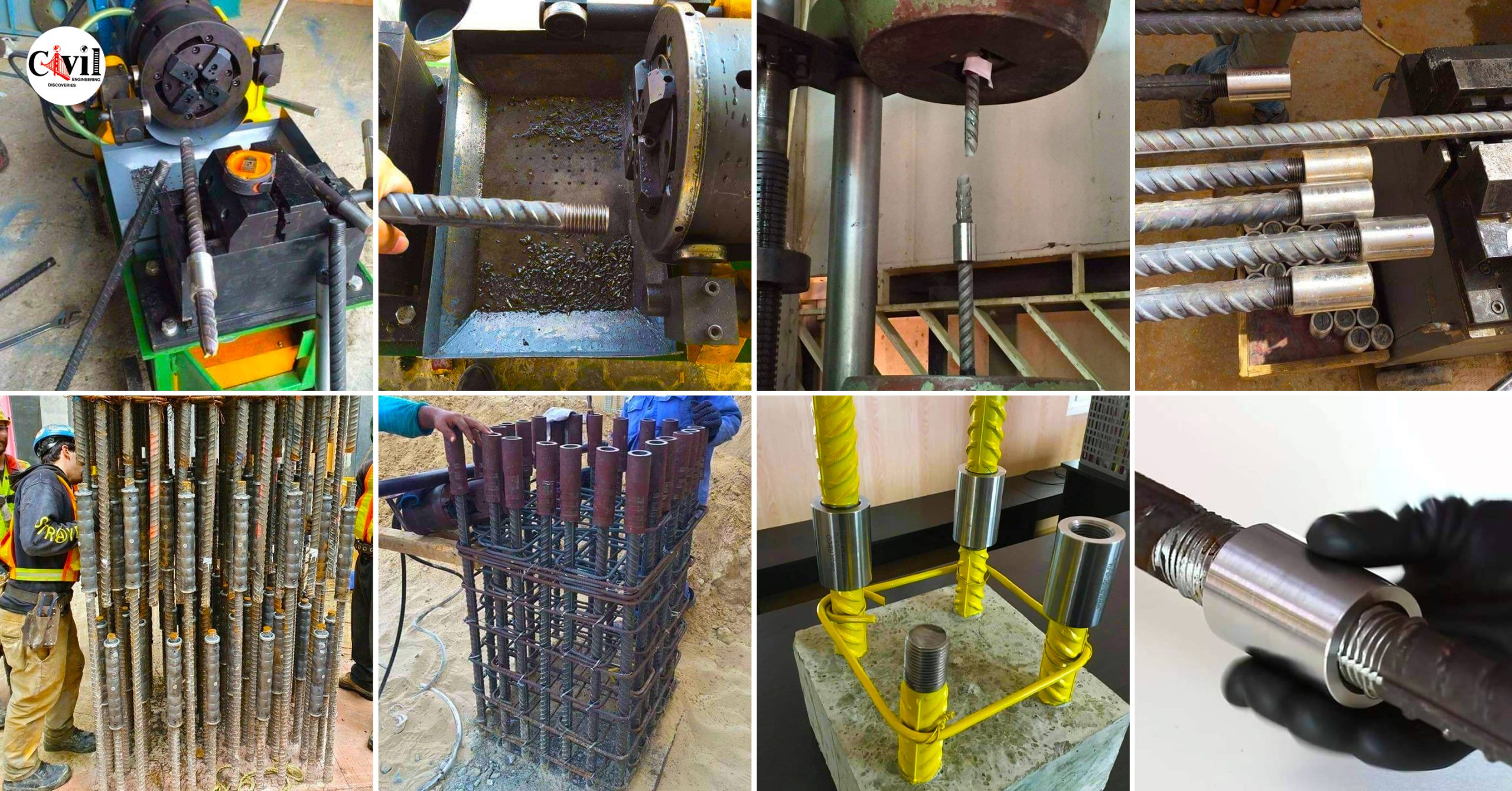

A rebar coupler, also known as a mechanical splice, is a device used to join two reinforcing bars (rebars) together in reinforced concrete structures. It is an alternative to lap splices or welded connections. Rebar couplers are typically made of steel and are designed to transfer the tensile and compressive forces between the two rebars.

Rebar Coupler is a system used for rebars Diameter greater than 36 mm …or Lapping is not allowable for rebars Diameter greater than 36 mm.

Advantages of using rebar couplers:

- Increased strength and stiffness: Rebar couplers can provide a stronger and stiffer connection than lap splices, especially for high-strength rebar.

- Improved concrete placement: Rebar couplers can eliminate protruding rebar ends, which can make it easier to place and consolidate concrete.

- Reduced congestion: Rebar couplers can reduce the amount of congestion in reinforced concrete members, which can make it easier to place and tie rebar.

- Reduced waste: Rebar couplers can eliminate the need for lap splices, which can save rebar and reduce waste.

- Improved worker safety: Rebar couplers can reduce the need for welding, which can improve worker safety.

Disadvantages of using rebar couplers:

- Cost: Rebar couplers are more expensive than lap splices.

- Installation: Rebar couplers must be installed correctly to ensure proper strength and stiffness.

- Quality control: Rebar couplers must be inspected and tested to ensure that they meet the required specifications.

Types of rebar couplers:

- Threaded couplers: Threaded couplers are the most common type of rebar coupler. They consist of a threaded sleeve that is screwed onto the ends of the two rebars.

- Sleeve couplers: Sleeve couplers consist of a sleeve that is slipped over the ends of the two rebars. The sleeve is then crimped or compressed to create a tight connection.

- Epoxy couplers: Epoxy couplers consist of a sleeve that is filled with epoxy resin. The ends of the two rebars are dipped into the epoxy resin and then inserted into the sleeve. The epoxy resin then cures to create a strong connection.

Choosing the right rebar coupler:

The type of rebar coupler that is best for a particular application depends on several factors, including the size of the rebar, the strength requirements of the connection, and the installation environment.

In general, threaded couplers are a good choice for general applications. Sleeve couplers are a good choice for applications where space is limited. Epoxy couplers are a good choice for applications where a very strong connection is required.

Click Here To See Water Bars (Water Stops) – Uses, Types, And Applications