A long cylindrical element in axial compression is the column. Column supports loads as well as its weight. Loads often transfer along their longitudinal direction. The height of the column determines its category. Modern buildings are designed with both compression and tension stress experienced by all the materials used. Concrete and steel are the two main components that makeup columns. Architects plan the interior elements of the structure, such as the foundation, beams, and columns, and they also compute the overall stress resulting from the building’s live and dead loads. Therefore, structures fail if the applied stress is higher than the calculated allowed stress.

Types of Column Failure

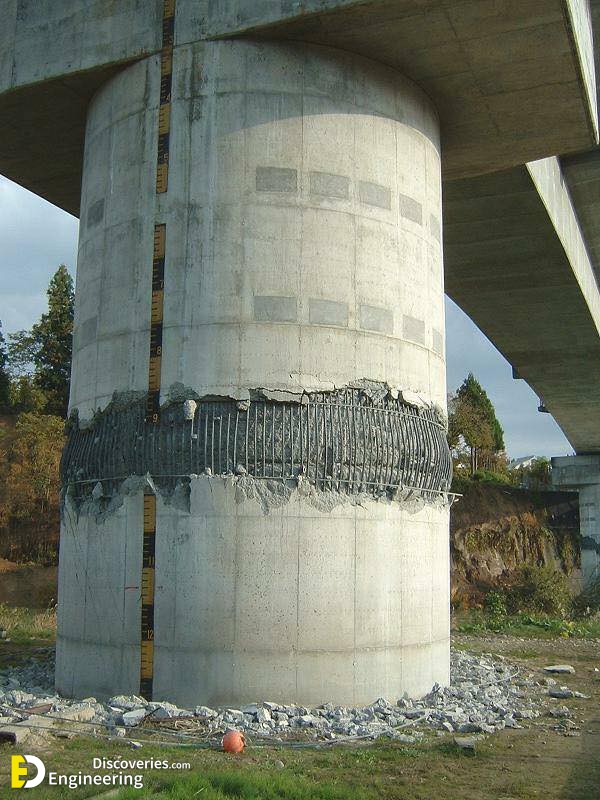

1. Compressive Failure

When columns are axially loaded, the concrete and steel will experience some stress. When the loads are greater in amount compared to the cross–sectional area of the column, the concrete and steel will reach the yield stress and failure will start without any later deformation. In this type of failure, the material fails itself, not the whole column. This type of failure mostly occurs in shorter and wider columns.

The columns should be made with a sufficient cross-sectional area compared to the allowable stress to avoid this.

Three factors are responsible for this issue. Number one is loading, number two is compressive strength, and number three is the cross-sectional area of the column.

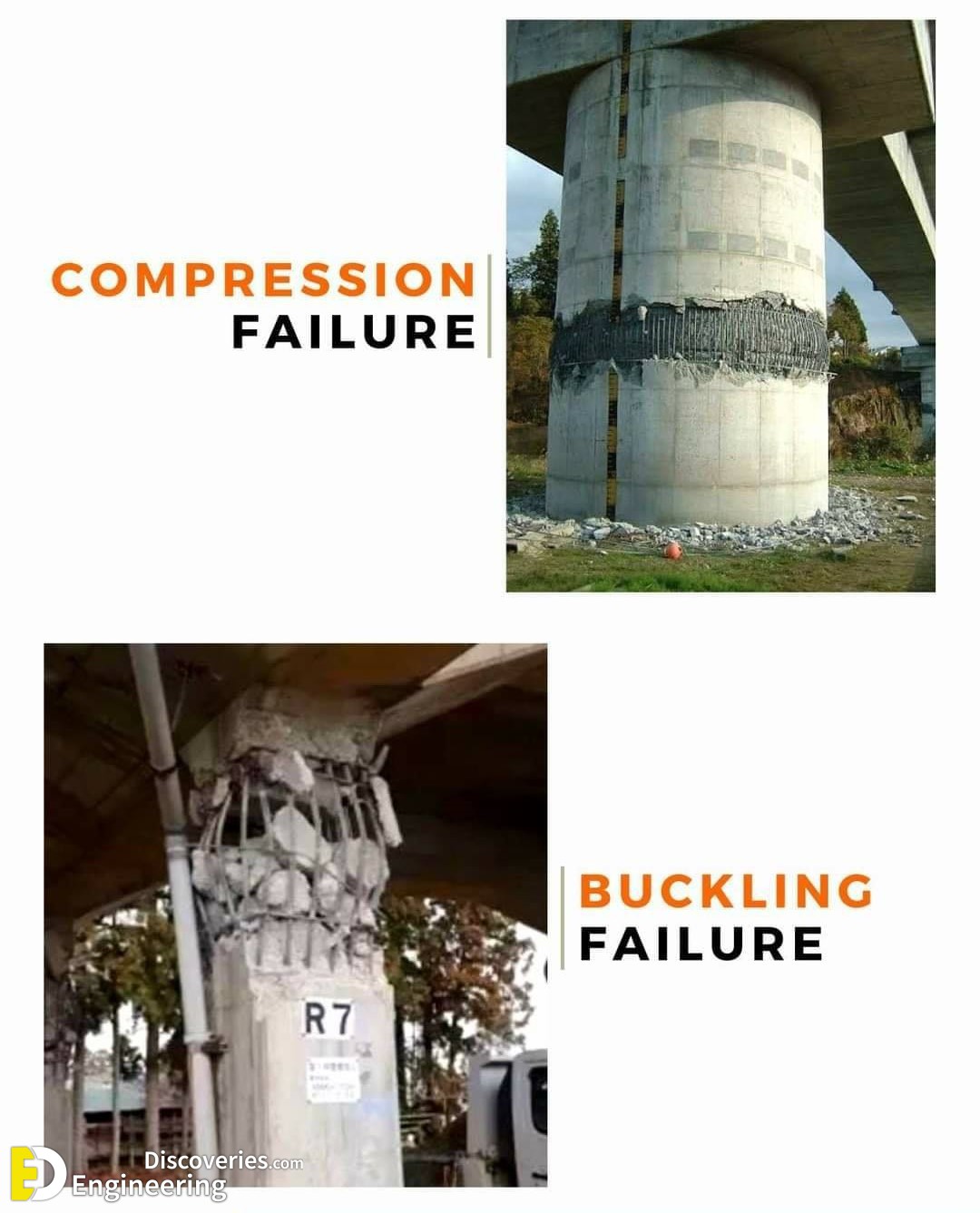

2. Buckling Failure

Buckling failure generally occurs in long columns. Because they are very slender and their least lateral dimension is greater than 12. In such conditions, the load-carrying capacity of the column decreases very much. The column tends to become unstable and start buckling sideward even under small loads. That means the concrete and steel reached their yield stress for even small loads and started failing due to lateral buckling.

This type of failure can be avoided by not constructing long columns with a slenderness ratio greater than 30.

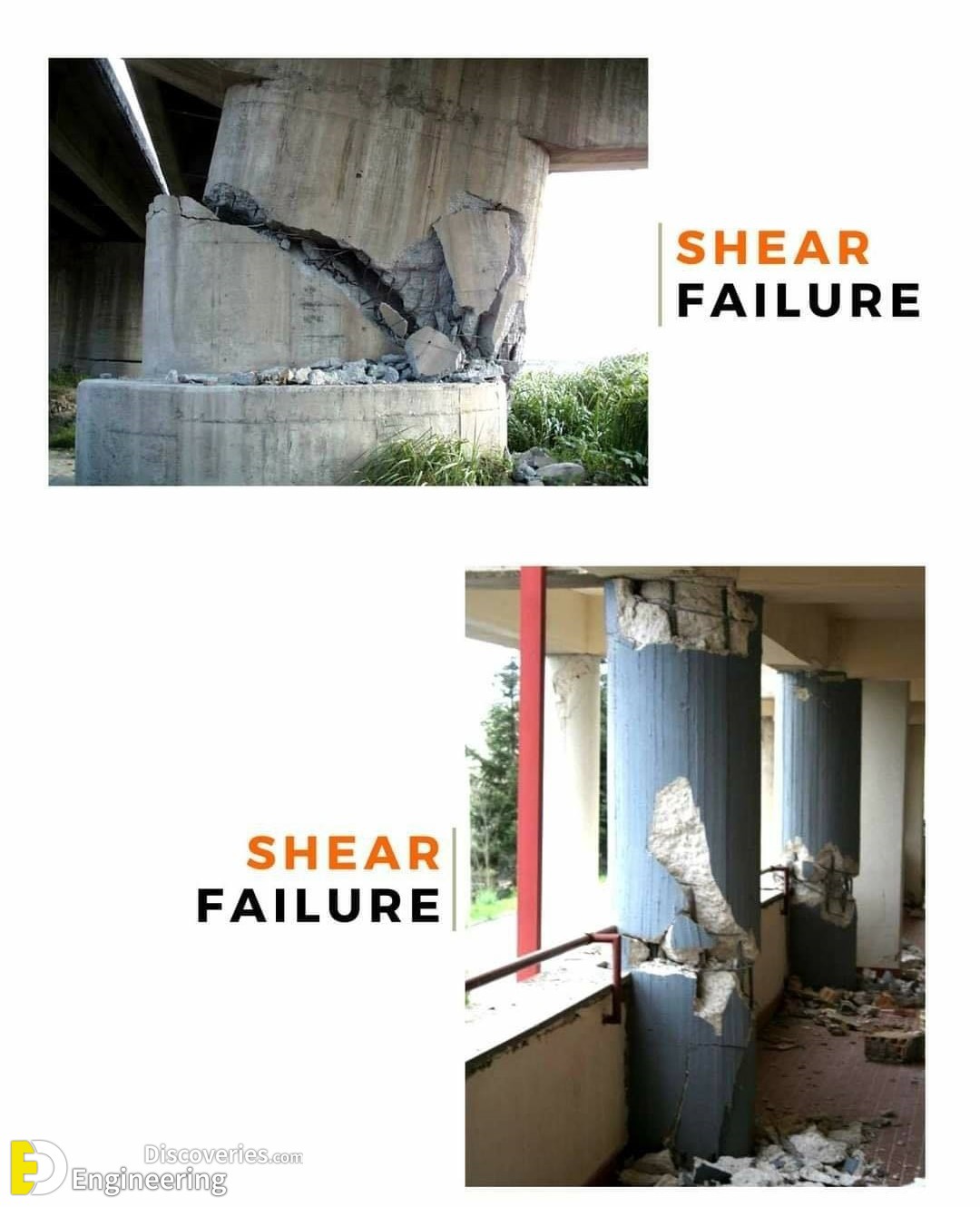

3. Shear Failure

Shear force tends to produce sliding failure on a material along a plane that is parallel or slightly parallel (diagonal) to the direction of the force. When the shear force exceeds the shear capacity of the column then this failure occurs.

Reasons for column failure

Column failure can be caused by several factors, including:

- Overloading: If the column is subjected to a load that is greater than its design load, it can fail.

- Poor design: If the column is not designed properly, it may be too slender or have insufficient reinforcement.

- Construction defects: If the column is not constructed properly, it may have voids or cracks that weaken it.

- Material defects: If the materials used to construct the column are defective, the column may fail.

- Corrosion: If the column is exposed to corrosion, it can weaken and fail.

- Fire: If the column is exposed to fire, it can weaken and fail.

Prevention of column failure

Column failure can be prevented by taking the following steps:

- Design columns properly: Columns should be designed to withstand the loads that they will be subjected to. The slenderness ratio of the column should be kept low, and sufficient reinforcement should be provided.

- Construct columns properly: Columns should be constructed properly to avoid voids and cracks.

- Use high-quality materials: High-quality materials should be used to construct columns to ensure that they have the required strength and durability.

- Inspect and maintain columns regularly: Columns should be inspected and maintained regularly to identify and repair any damage or defects.

Click Here To See Significant RCC Information About Footings, Beams, Columns, Slabs, And Stairs