1. Longitudinal Joints: The joints which are provided parallel to the center line of the pavement, are called longitudinal joints.

2. Transverse Joints: The joints which are provided at right angles to the center line of the pavement are called transverse joints.

1. Transverse Joints

(i) Expansion joint

(ii) Contraction joint

(iii) Warping joint

(iv) Construction joint

(i) Expansion Joints

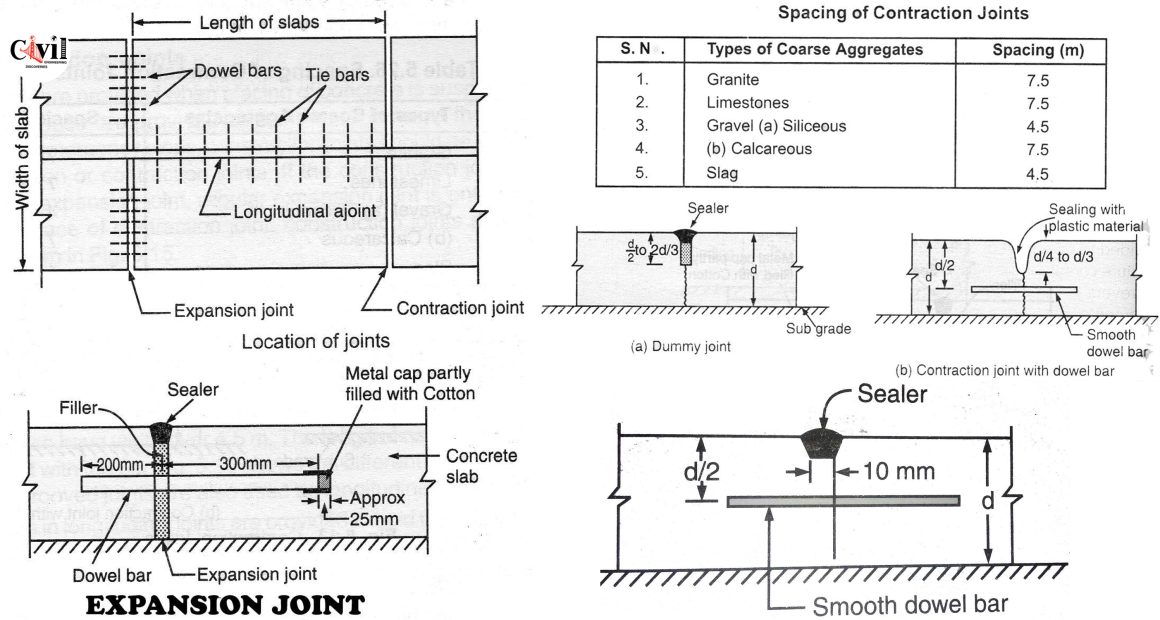

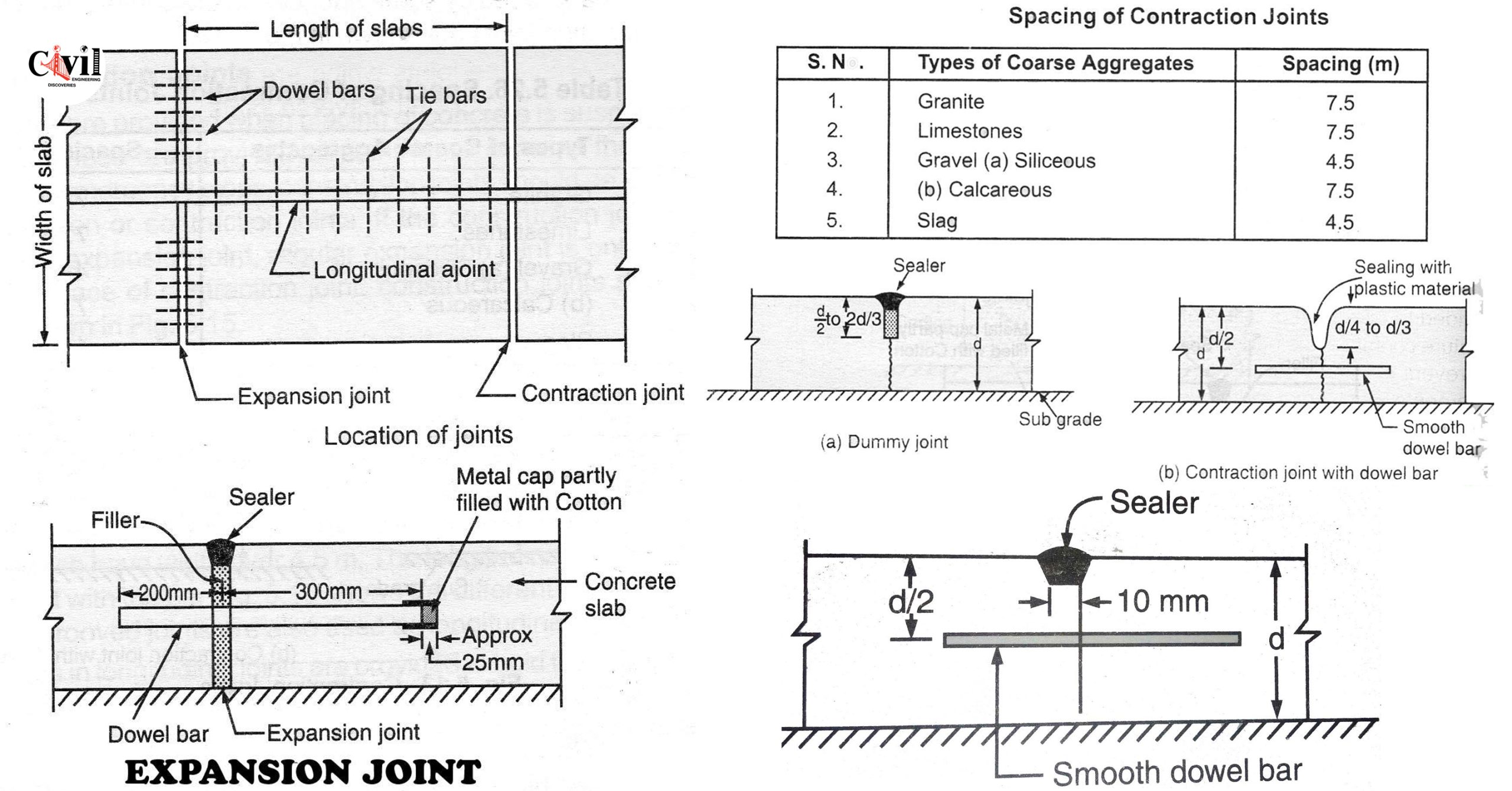

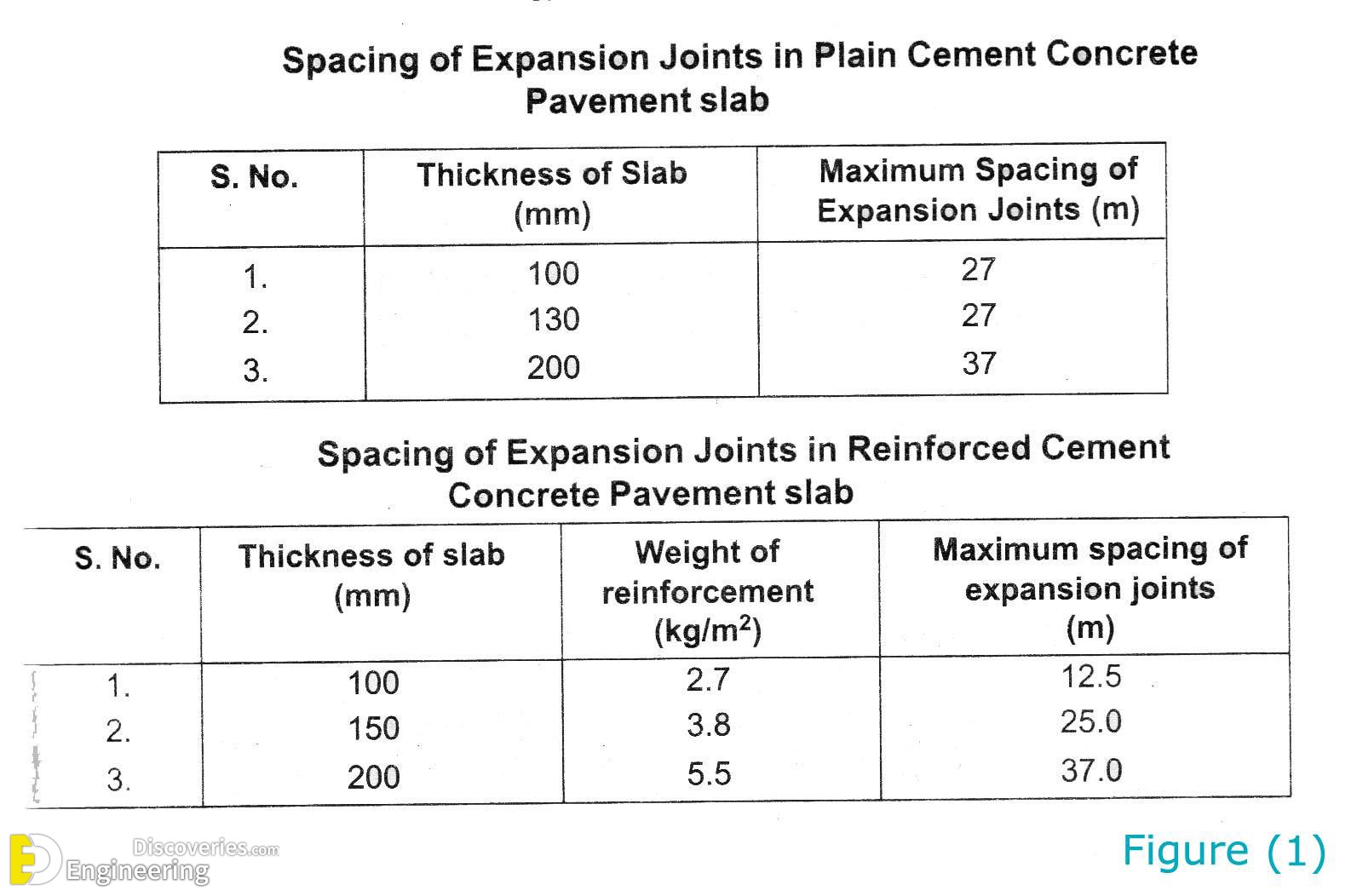

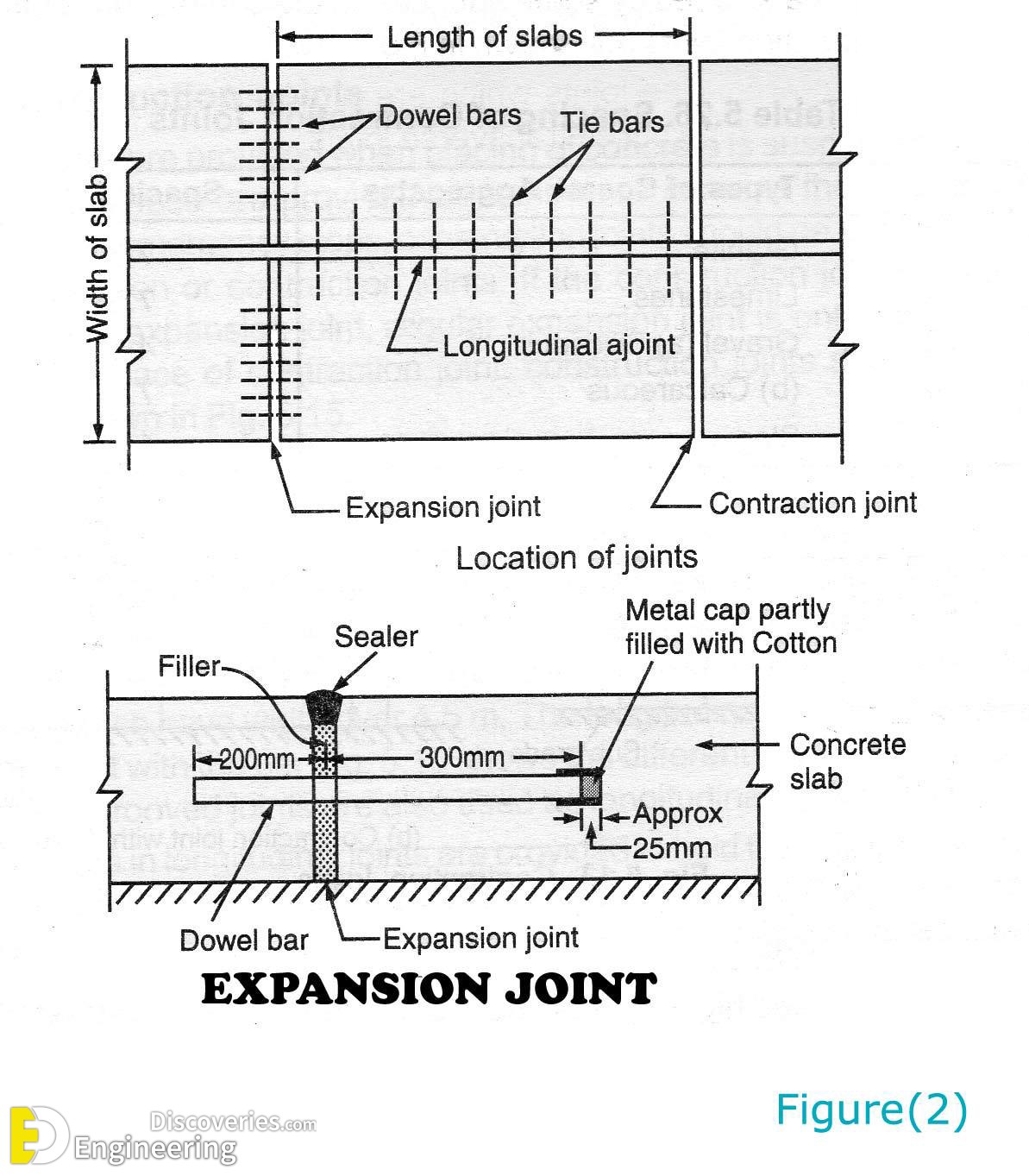

These joints are provided to allow for the expansion of the slab due to a rise in the slab temperature. Expansion joints also permit the contraction of the slab and help to reduce warping stresses. The gap width for this type of joint is between 20 mm to 25 mm. Dowel bars are used to transfer the load to the adjoining slab. One end of the dowel bar is embedded effectively in one slab and the other end is kept free to allow for expansion. These bars are 20 to 30 mm in diameter and 400 to 700 mm in length. These bars are provided at an interval of 300 mm. The spacing of these joints is given in Figure (1). A typical expansion joint is shown in Figure (2).

(ii) Contraction Joints

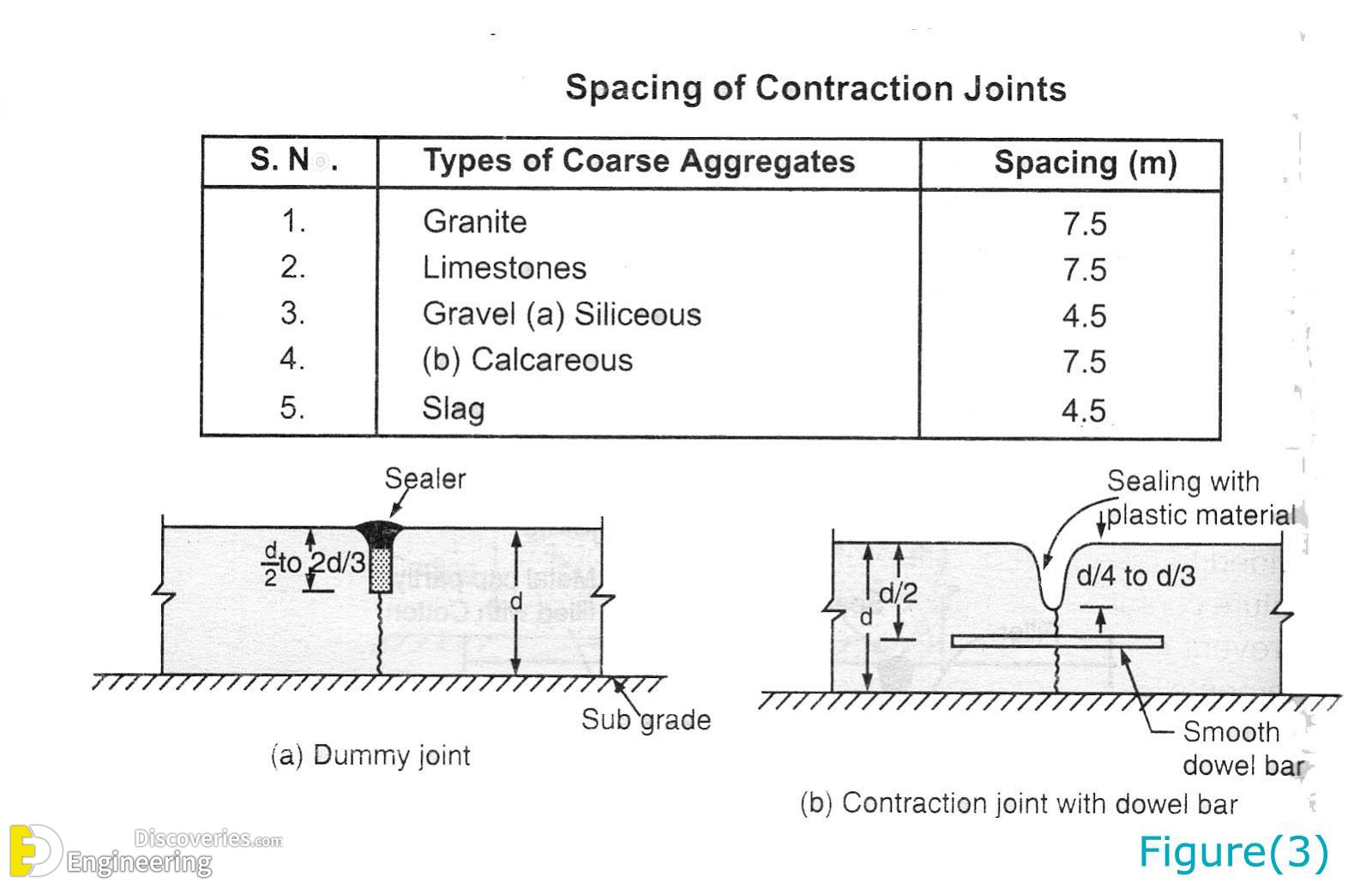

These joints are provided to receive tension developed in concrete due to contraction. Contraction joints are spaced closer than the expansion joints. Depending upon the type of aggregates employed in the construction, the recommended spacing of contraction joints is given in Figure (3).

The transfer of load at the joints is provided by the physical interlocking of the aggregates projecting out at the joint faces. A fully bounded dowel bar is also used by some agencies in the contraction joints for added safety.

(iii) Warping Joints

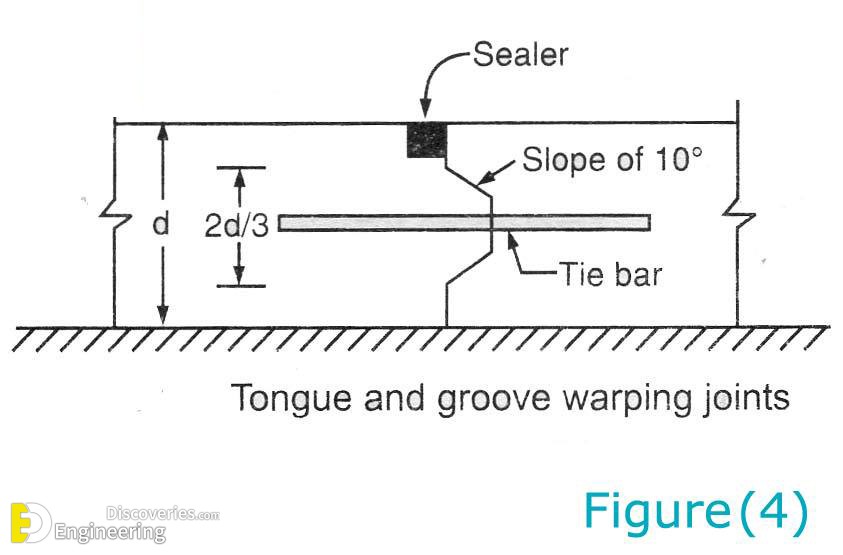

These are also called higher joints and are provided to relieve stresses including due to warping. These joints are simply breaks in the continuity of concrete which allows a small amount of angular movement to occur between adjacent slabs. These joints are rarely needed if properly designed expansion and contraction joints are provided to prevent cracking. Warping joints are of two types. shown in Figure (4).

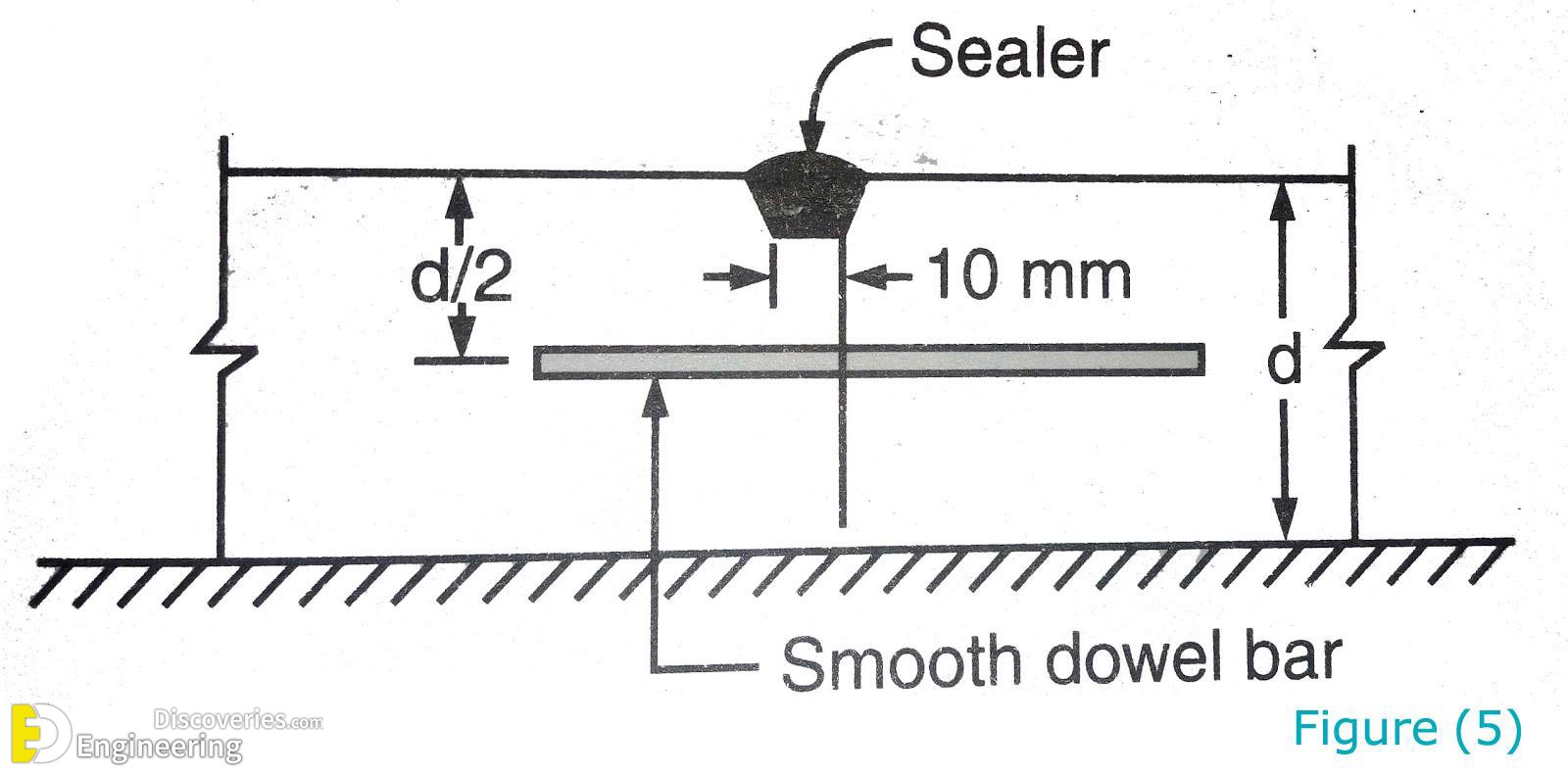

(iv) Construction Joints

These joints are provided when placing concrete suspended for more than 30 minutes. These are provided as transverse joints at the end of each day’s work. Except for emergency stops, construction joints should be located at the regular place of expansion or contraction joints. If the construction joint is located at the place of the regular expansion joint, the regular expansion joint is only constructed. If it is located at the place of the contraction joint, construction joints should be used with dowel bars, shown in Figure (5).

2. Longitudinal Joints

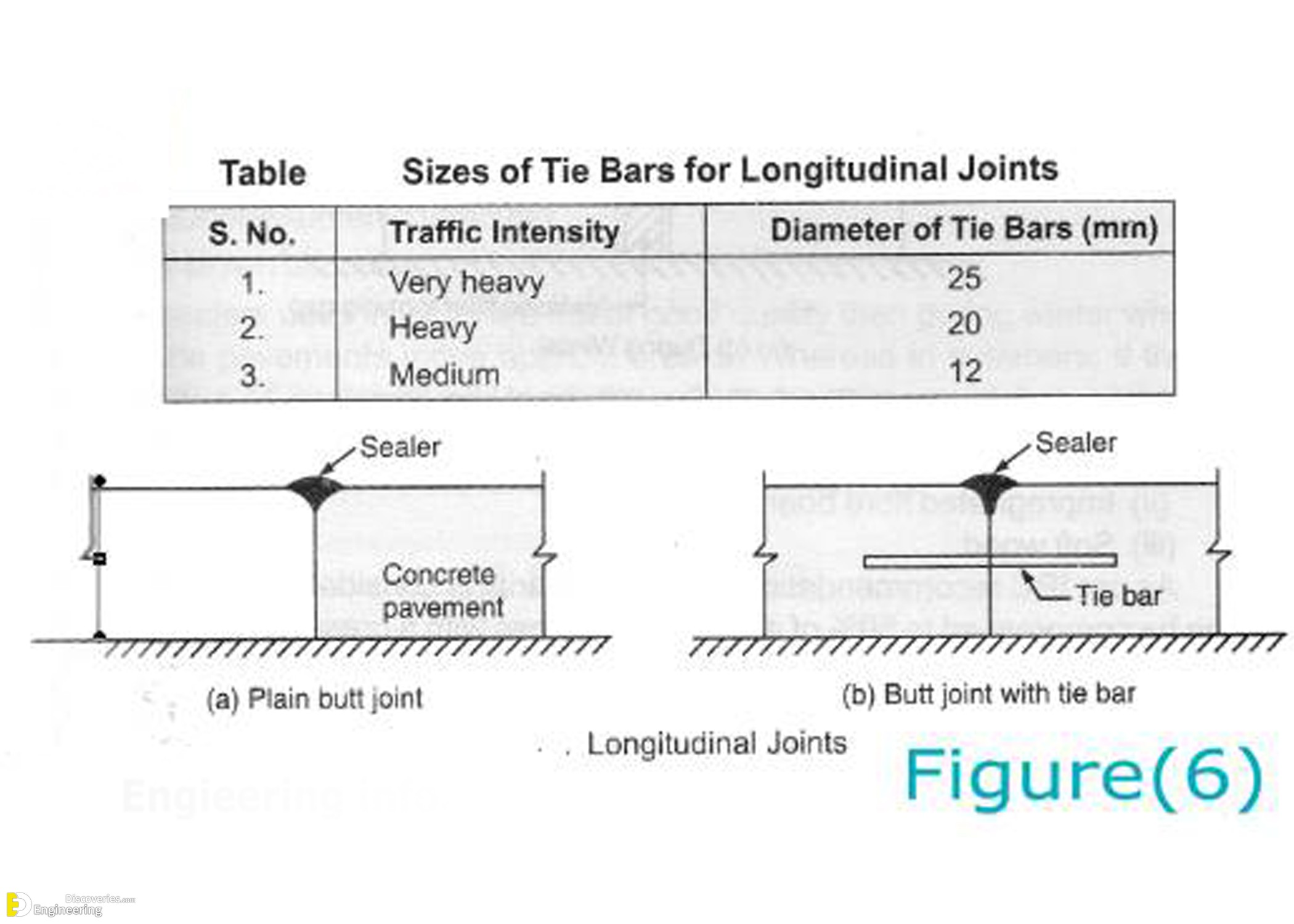

On the Subgrade of clay soil, longitudinal joints in cement concrete pavements are provided to take care of differential shrinkage and swelling due to rapid change of moisture content at the edges of the slab than at the center. These joints are provided to prevent longitudinal cracking in the concrete pavements and are provided to pavements that have a width over 4.5 m. The longitudinal joints are either plain butt joints or butt joints with the bar, Figure (6) shows the different types of longitudinal joints.

Tongued and grooved joints are also used as longitudinal joints.

The tie bars in longitudinal joints are provided to hold the adjacent slabs together.

The length and spacing of tie bars adopted are 1.05 m and 0.60 m center to center respectively. Table 3 gives the recommended size of tie bars based on the traffic intensity.

Joint Filler and Sealer

The continuity of concrete pavement is broken at the place of the joint. If these joints are not filled properly these can allow the infiltration of water and ingress of stone grits. The filling materials used in the joints are called filler and sealer. First, the joint space is filled with compressible filler material and the top of the joint is then sealed by using a sealer.

A. Joint Filler

The joint filler should possess the following properties:

- Durability

- Compressibility and

- Elasticity.

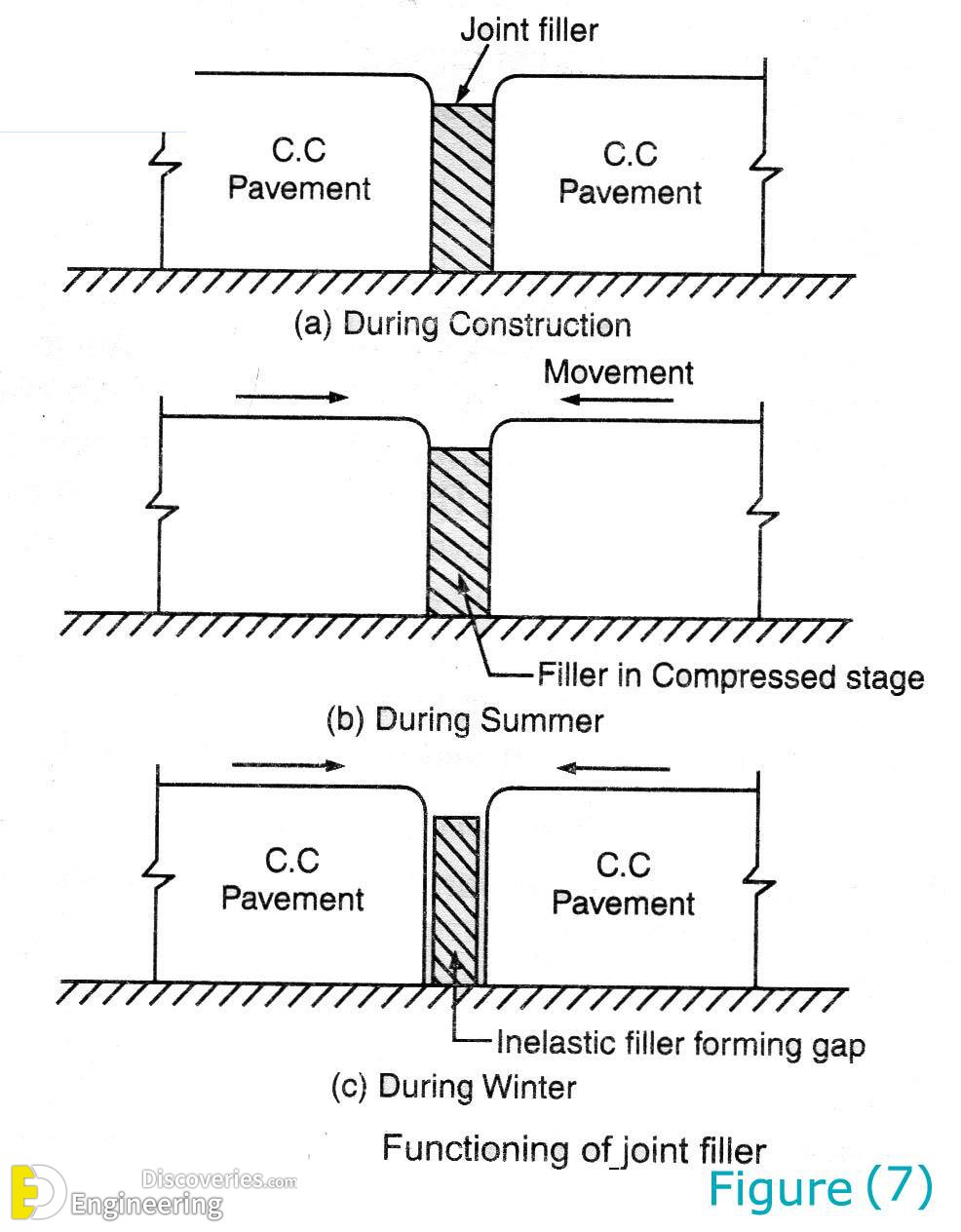

The filler material should be compressible and elastic because during summer the pavement expands and reduces the gap of the joint. At this time the filler is compressed. Whereas, during winter the pavement edges move back and if the filler is inelastic, there will be the formation of a gap as shown in Figure (7).

B. Joint Sealer

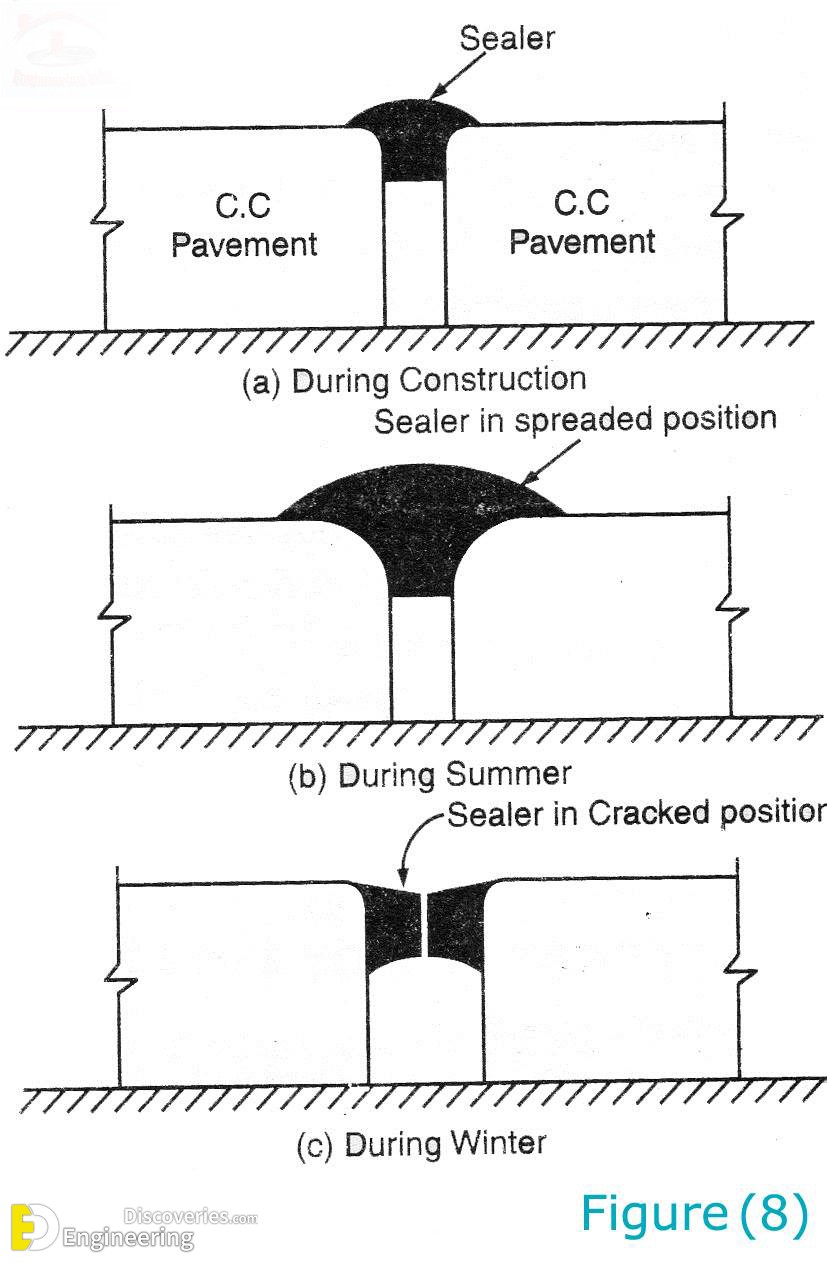

After filling of joint, sealing is done by using a joint sealer. A joint sealer should possess the following properties for effective sealing. shown in Figure (8).

- Durability

- Resistance to ingress of grit

- Adhesion to cement concrete edges

- Extensible without fracture.

Following are the different types of sealing material in use:

- Bitumen

- Rubber-bitumen compound

- Air blown bitumen

If the sealers used in joints are not of good quality then during winter when the edges of the pavements move apart, it breaks. Whereas in summer, if the flow characteristics of the sealer are not good, the sealer material would flow and spread around the joints, spoiling the appearance and smoothing riding.