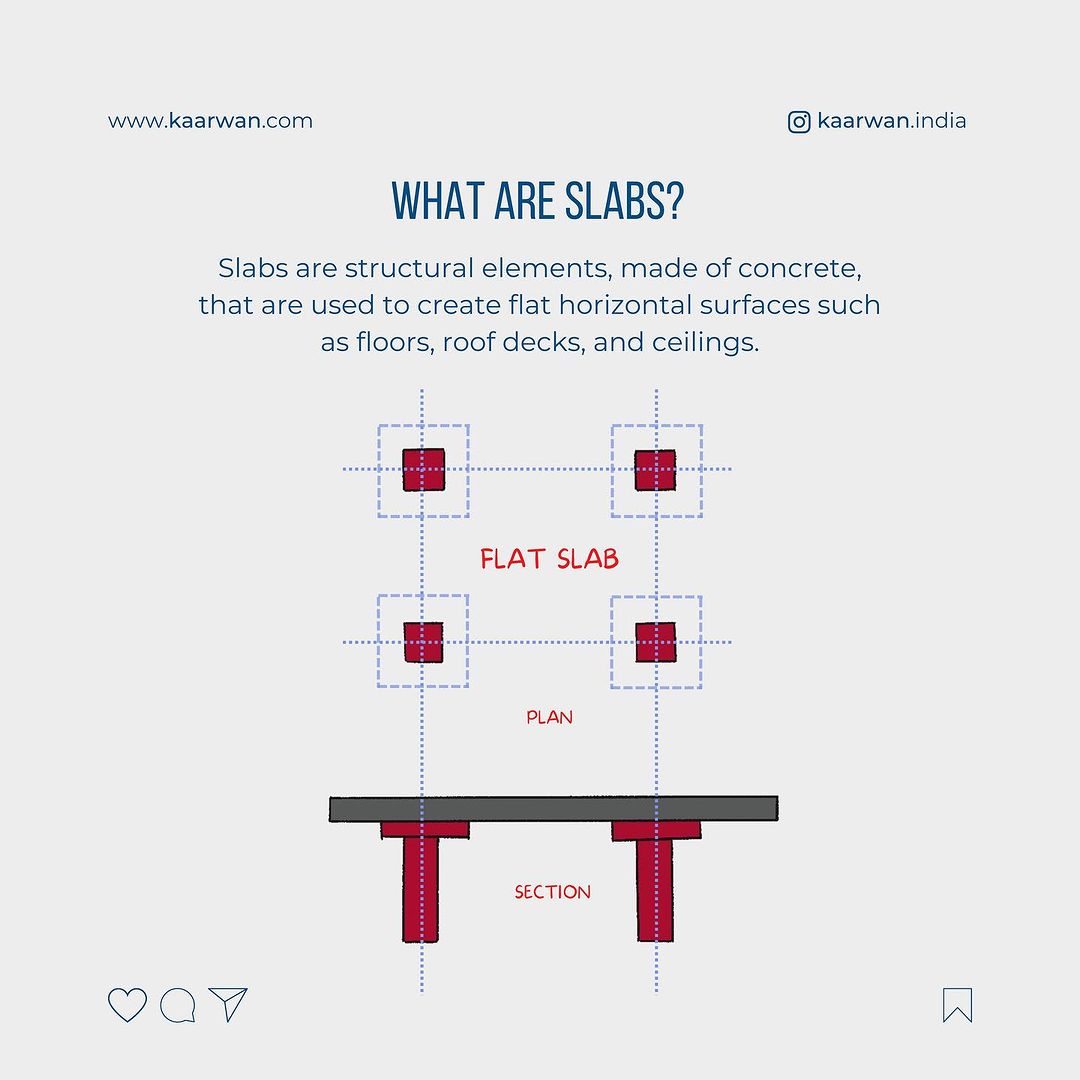

Slabs are essential structural elements in construction that provide horizontal surfaces in buildings, often serving as floors, roofs, or even ceilings. Their primary function is to support loads and transfer them to the supporting columns and beams. Depending on the design, purpose, and span required, different types of slabs are used. Understanding these slab types, their design considerations, and their applications can greatly enhance the strength and efficiency of a structure.

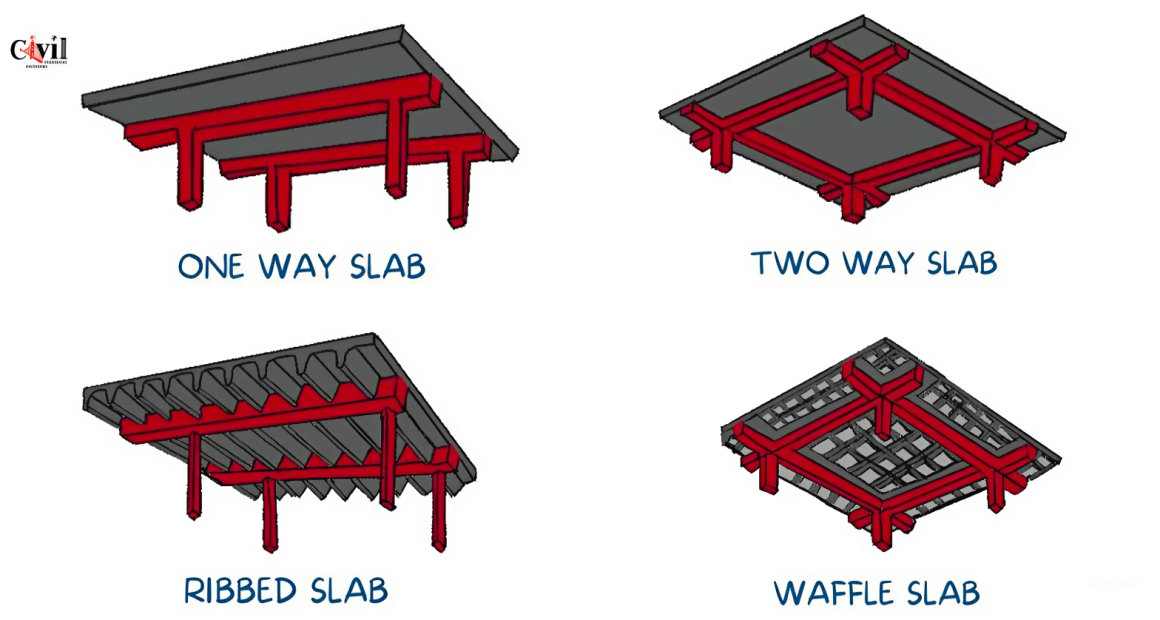

This article explores the four main types of slabs—One-Way Slab, Two-Way Slab, Ribbed Slab, and Waffle Slab—and delves into the factors that affect slab selection, construction methods, and future innovations in slab technology.

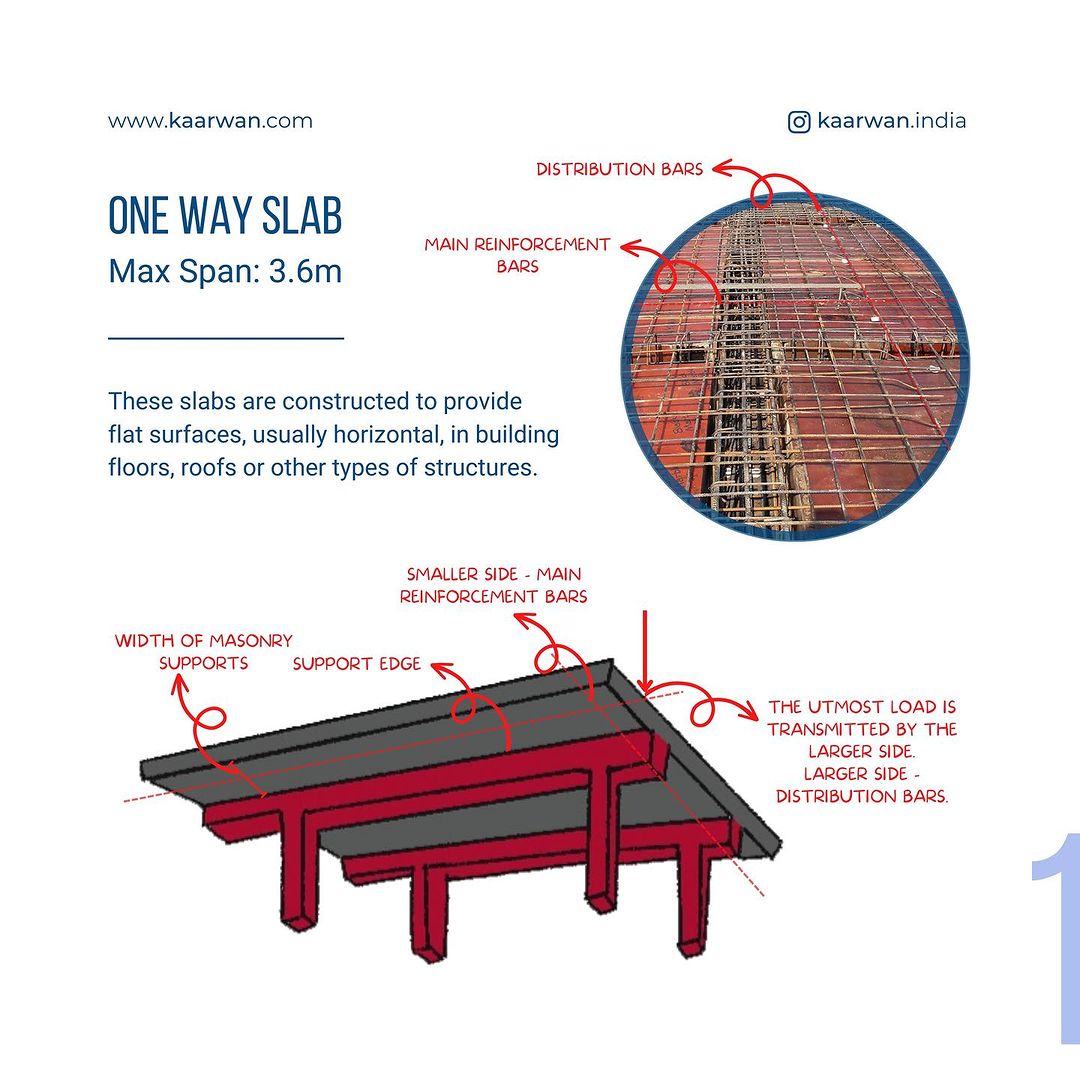

1. One-Way Slab

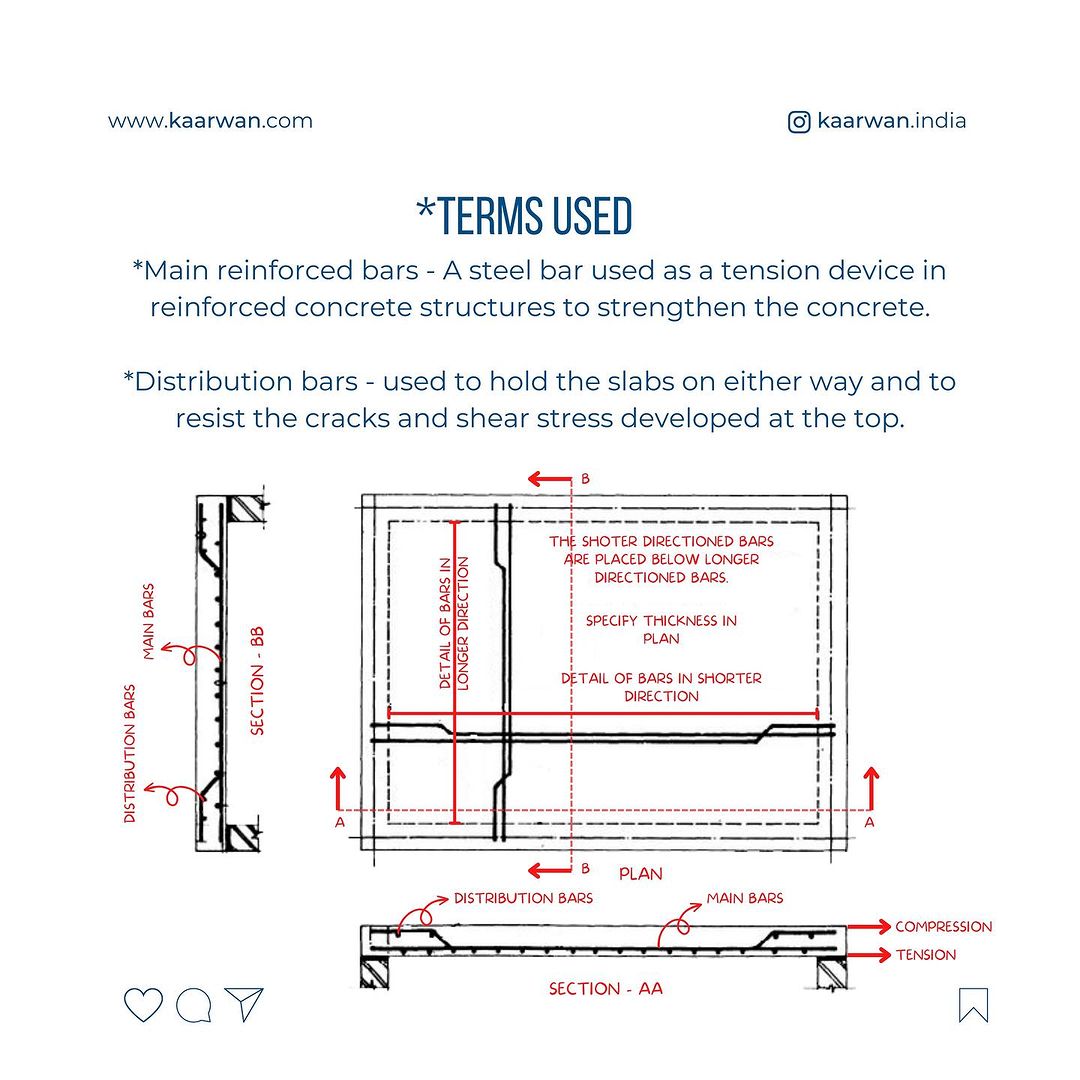

A one-way slab is a type of slab that primarily spans in one direction between two parallel supports. In this slab, the longer side usually exceeds twice the length of the shorter side. This type of slab is designed to transfer the load primarily in one direction.

- Maximum Span: 3.6 meters.

- Features: One-way slabs are used in structures where the spans are relatively short and the loads are moderate. These slabs are commonly found in residential buildings, car parks, and small commercial establishments.

- Design Considerations: Reinforcement is typically provided along the shorter span, as it carries the primary load. The thickness of the slab and the quality of the concrete used will vary based on the load-carrying requirements.

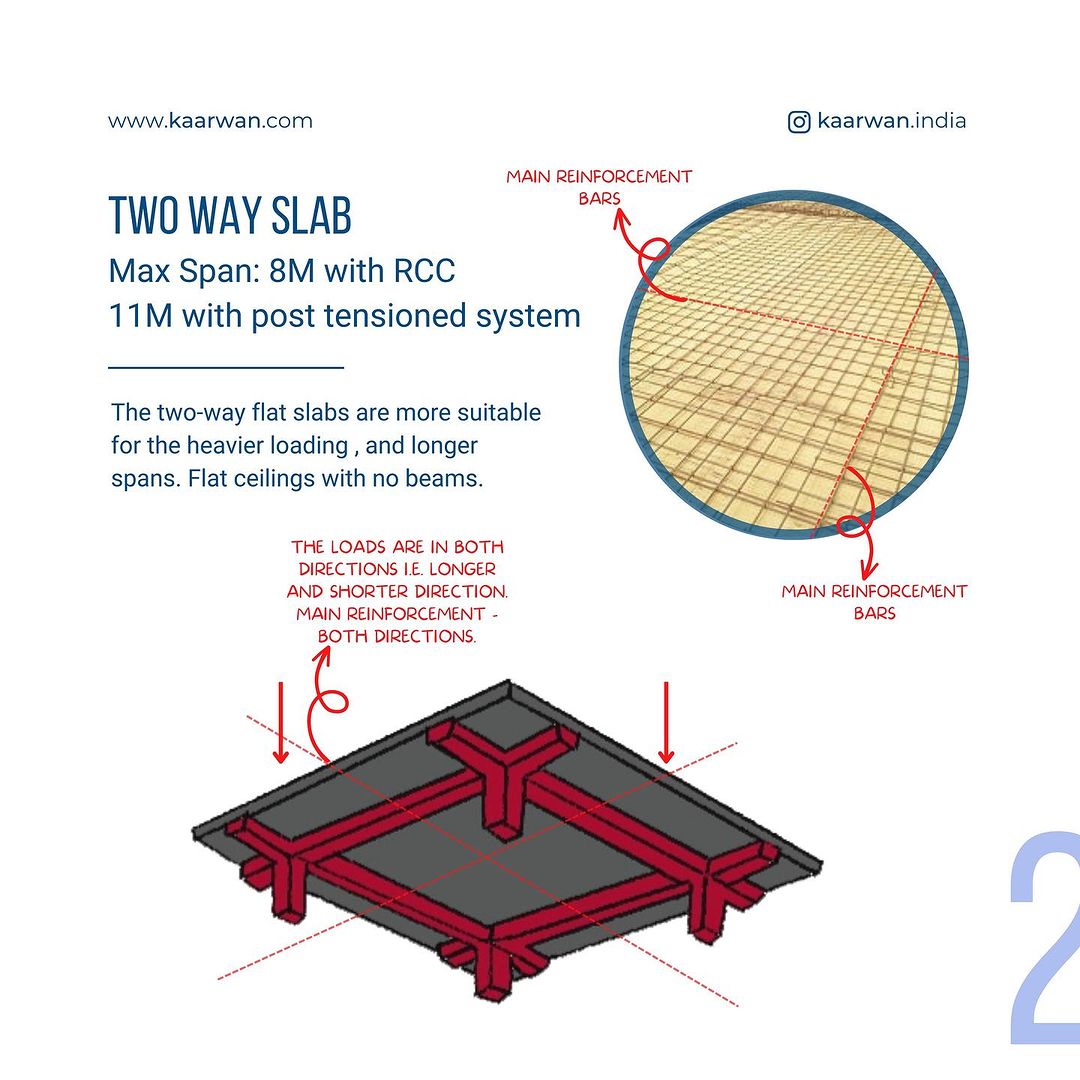

2. Two-Way Slab

Two-way slabs, unlike one-way slabs, distribute loads in two directions. These slabs are supported on all four sides, and the span length does not exceed twice the shorter span. Due to their versatility and ability to handle larger spans, they are commonly used in commercial and industrial buildings.

- Maximum Span: 8 meters.

- Features: Two-way slabs provide better load distribution and are more suitable for heavier loads. They can be designed with or without beams, depending on the application.

- Advantages Over One-Way Slabs: Two-way slabs offer more flexibility in design, especially when creating flat ceilings without beams. This makes them ideal for larger, open spaces that require minimal internal support.

3. Ribbed Slab

Ribbed slabs are used when long spans are required without increasing the overall weight of the structure. These slabs consist of a series of narrow, deep beams or “ribs,” which provide added structural strength while minimizing material usage.

- Maximum Span: 16 meters.

- Usage in Steel vs. Concrete Buildings: Ribbed slabs are often used in steel structures due to their ability to cover longer spans with less material. However, they are also found in some concrete buildings, particularly where lighter slabs are needed.

- Structural Benefits: The ribbed design reduces the overall weight of the slab while maintaining its strength, making it suitable for large halls, theaters, or industrial buildings.

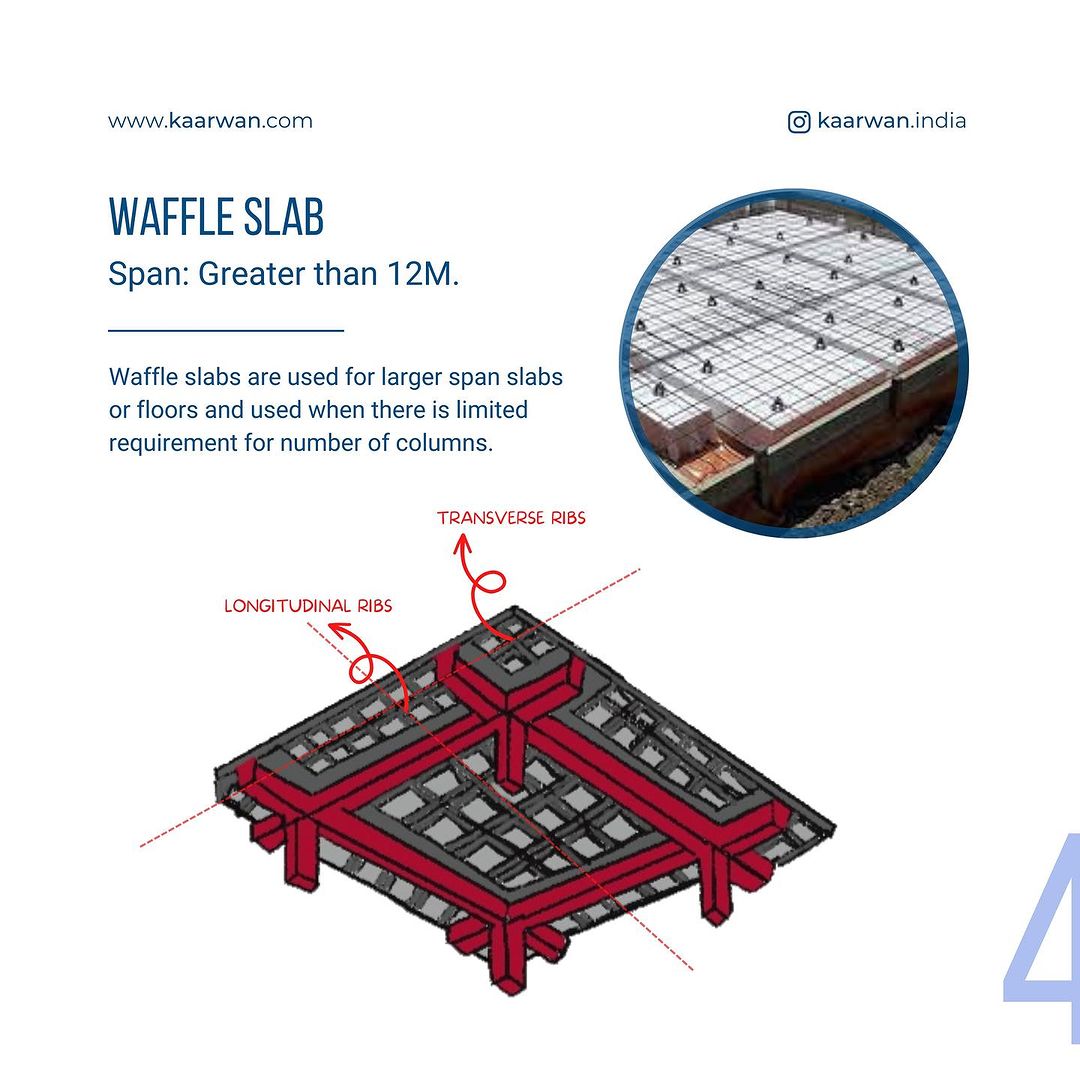

4. Waffle Slab

Waffle slabs are similar to ribbed slabs but feature a grid pattern of ribs, resulting in a waffle-like appearance on the underside. This design is used in structures that require large spans without many columns.

- Maximum Span: Greater than 12 meters.

- Applications: Waffle slabs are typically used in spaces like auditoriums, car parks, or warehouses where column-free spaces are preferred. They provide both aesthetic appeal and structural integrity.

- Comparison with Ribbed Slabs: While ribbed and waffle slabs aim to reduce weight, waffle slabs offer a higher load-carrying capacity for larger spans. They also provide better thermal insulation due to the air pockets formed by the waffle design.

Design and Load Distribution

Understanding how slabs transfer loads is crucial in selecting the right slab type for any structure. One-way slabs transfer loads in one direction, while two-way slabs distribute the load in both directions. Ribbed and waffle slabs, conversely, provide superior load-bearing capacity with less material, making them ideal for larger and more complex structures.

Click Here To See Various Reasons For Cracks On A Concrete Slab

Photo Credit: kaarwan