We use the same bars( which are available in the market) in all structures. we do not manufacture different bars for different structural elements. The diameter of the bar will vary according to the load condition.

Bars in slab

like in slab we generally use 8mm, 10mm, 12mm because the load is less as compared to beam, column, footing.

Note: 8mm bar generally used in one way slab as distribution bar (secondary steel)

Bars in beam

In beam, we use bars having diameter Greater than 12mm (depends upon load)

Bars in column

In the column, we use Greater than 12 mm (depends upon load)

Bars in footing/foundation

Similarly, for footing, we use 10 mm or more than that (depends upon loading)

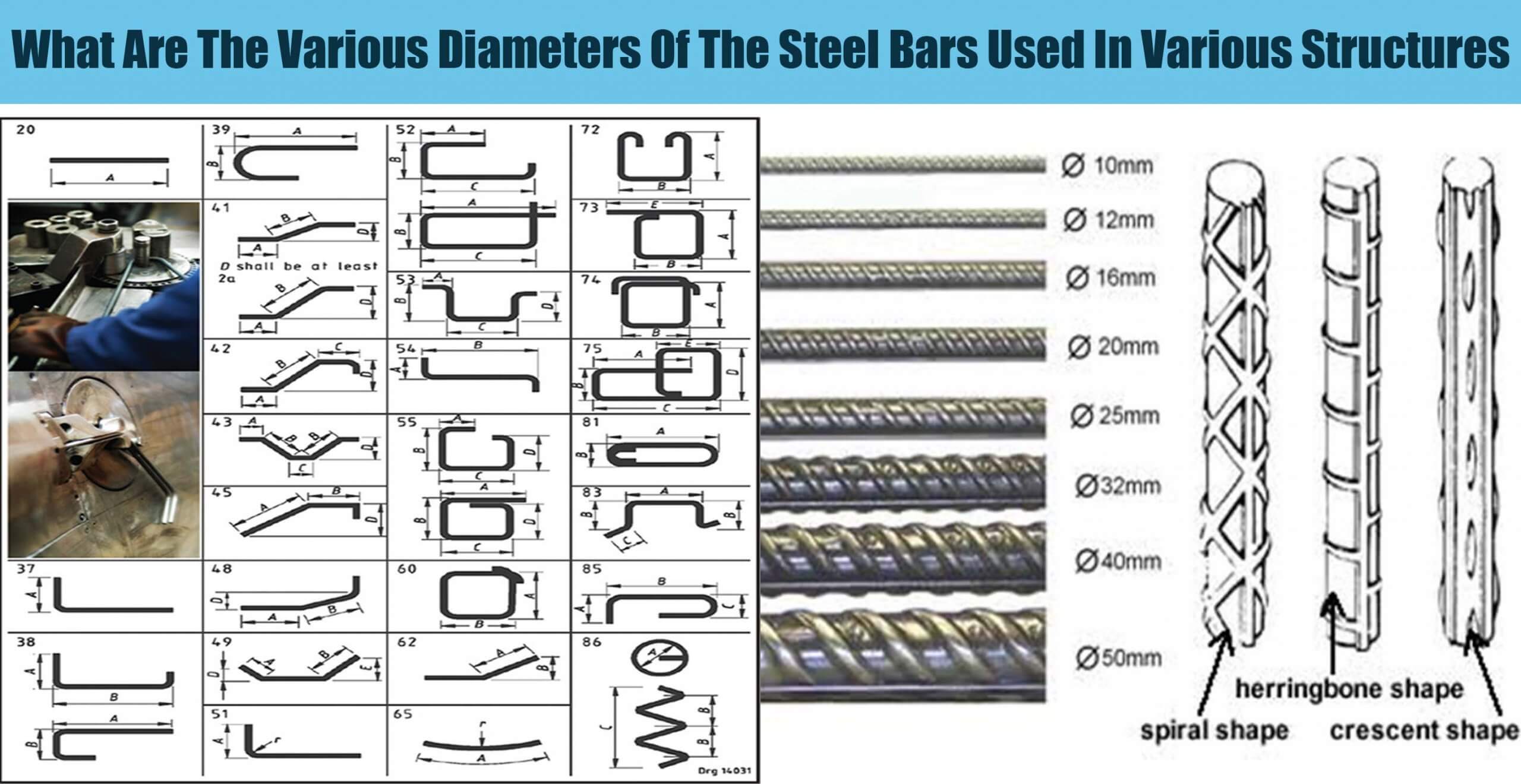

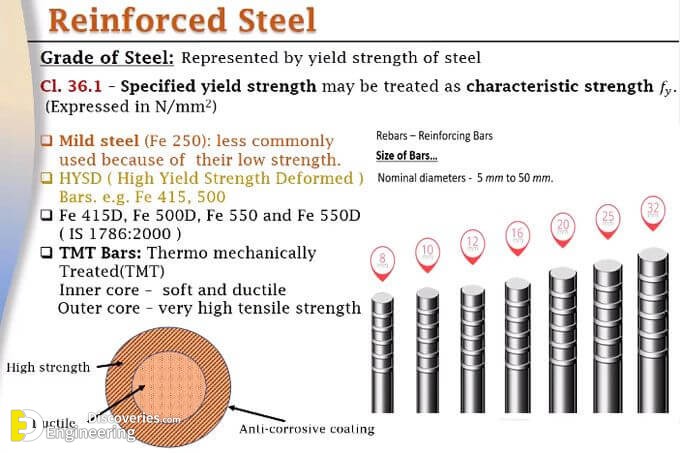

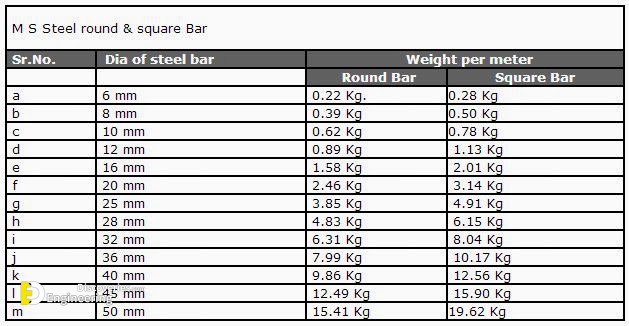

Bars which are available in the market are 8 mm, 10 mm, 12 mm, 16 mm, 20 mm, 25 mm, 28 mm, 32 mm, 36 mm and 42 mm

Greater diameter like 64 mm and 128 mm has to be ordered specially from steel plant for manufacturing

Note:

Q 1: why we are not using 14 mm bar?

There is no specific reason for not using a bar of 14,18, 22 mm etc diameter bar. I have mentioned the bars which are available in the markets. As i mentioned in the first line of this post we use the bars which are available in the market.

Q 2: How do we decide the number of bars and which diameter of bars to use?

We decide the number of bars and the diameter of the bars based on the area of reinforced is required and convince of placing concrete.