Reinforced Concrete

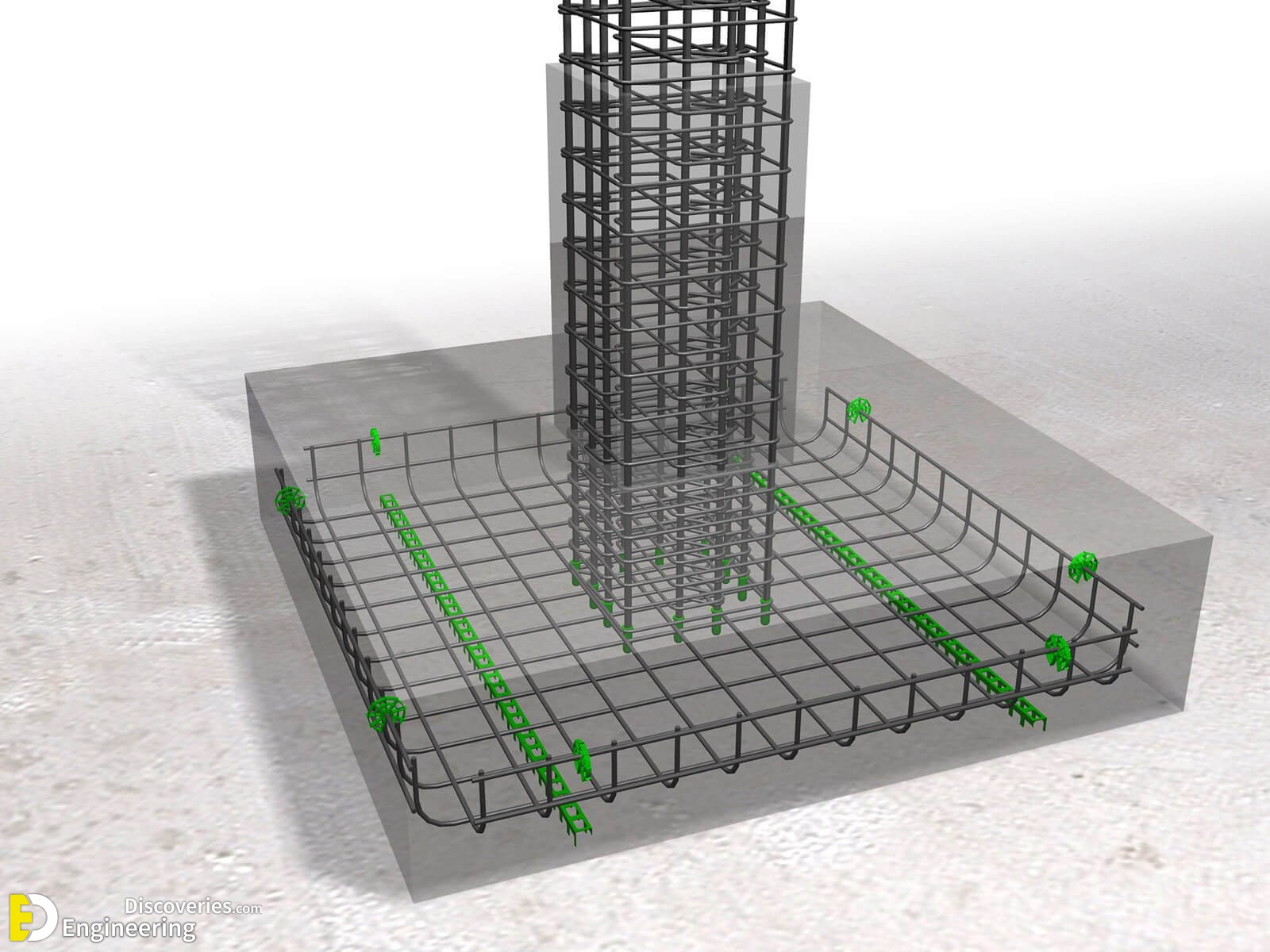

1- Reinforced Concrete (RC) is a composite material in which concrete’s relatively low tensile strength and ductility are counteracted by the introduction of reinforcement having higher tensile strength and ductility.

2- The reinforcement is usually, though not necessarily, steel reinforcing bars (rebar) and is usually embedded passively in the concrete before the concrete sets. Modern reinforced concrete can contain varied reinforcing materials made of steel, polymers or alternate composite material in conjunction with rebar or not.

3- Reinforcing schemes are generally designed to resist tensile stresses in particular regions of the concrete that might cause unacceptable cracking or structural failure.

Prestressed concrete

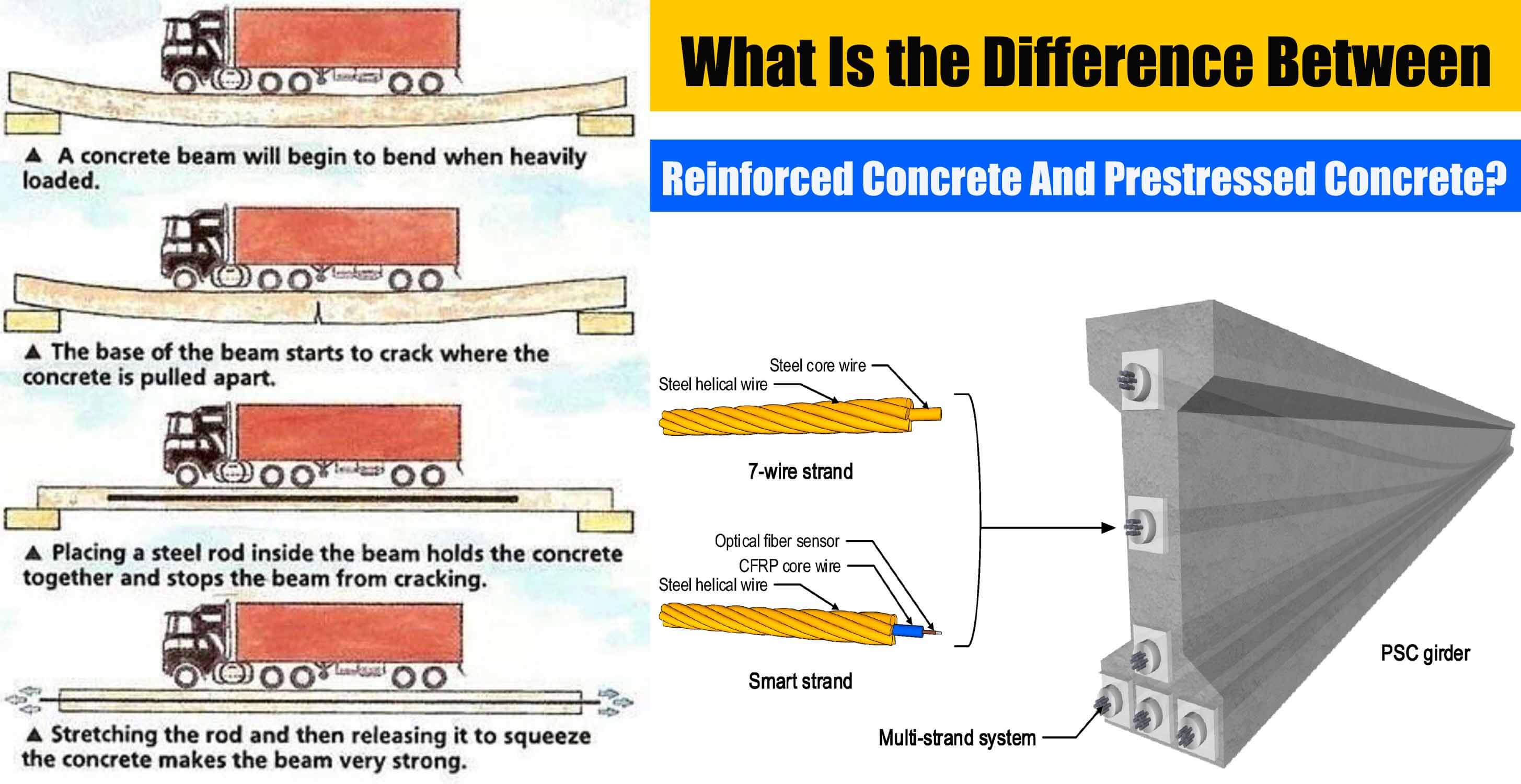

1- P.S.C. is a Structural concrete in which internal stresses have been introduced to reduce potential tensile stresses in the concrete resulting from loads.

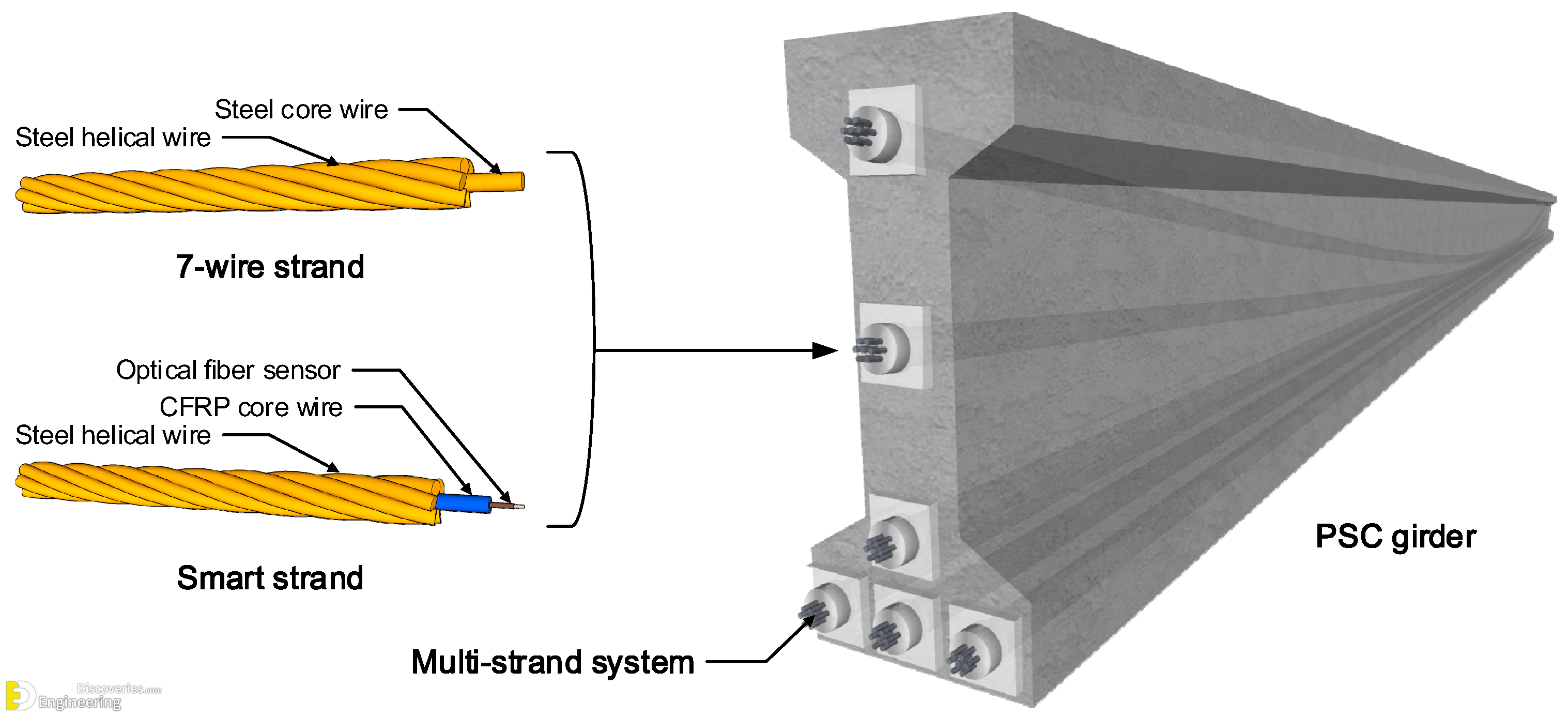

2- This compression is produced by the tensioning of high-strength “tendons” located within or adjacent to the concrete volume, and is done to improve the performance of the concrete in service.

3- Tendons may consist of a single wire, multi-wire strands or threaded bars, and are most commonly made from high-tensile steels, carbon fibre or aramid fibre.

Advantages of P.S.C over R.C.C

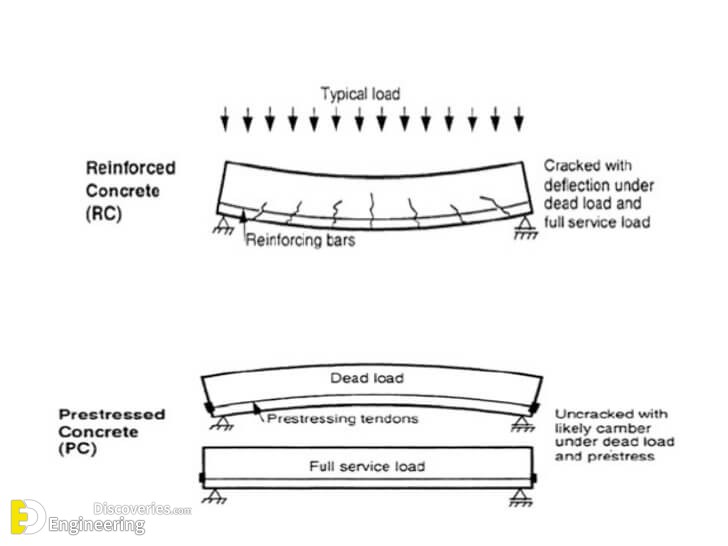

1- P.S.C. is more durable since there are no tensile cracks, whereas in R.C.C tensile cracks are unavoidable, hence there is greater danger of adverse environmental effects.

2- As high strength concrete is used and also since dead load moments can be neutralized P.S.C., deadweight of P.S.C. member is much less compared to what is required for R.C.C. member. The deadweight of P.S.C member is about one-third of equivalent R.C. members.

3- The material cost in P.S.C. is much less than that in equivalent R.C. members.

4- The deformation of P.S.C. members is much less compared to that for an equivalent R.C. member. In case of beams deflection of P.S.C. beams is about one – Fourth of that of equivalent R.C. beams.

5- P.S.C has high resilience that is., a considerable capacity for recovering completely from the effect of occasional overloadings, without suffering any serious harm. In the case of P.S.C. cracks in such situation which develop temporarily will close up completely.

6- The fatigue strength of the P.S.C. is very good.

Disadvantages of P.S.C over R.C.C

1- It requires skilled labour and good quality control.

2- It needs a special technique to apply prestressing forces and Anchorage the wires.

For more information watch this video