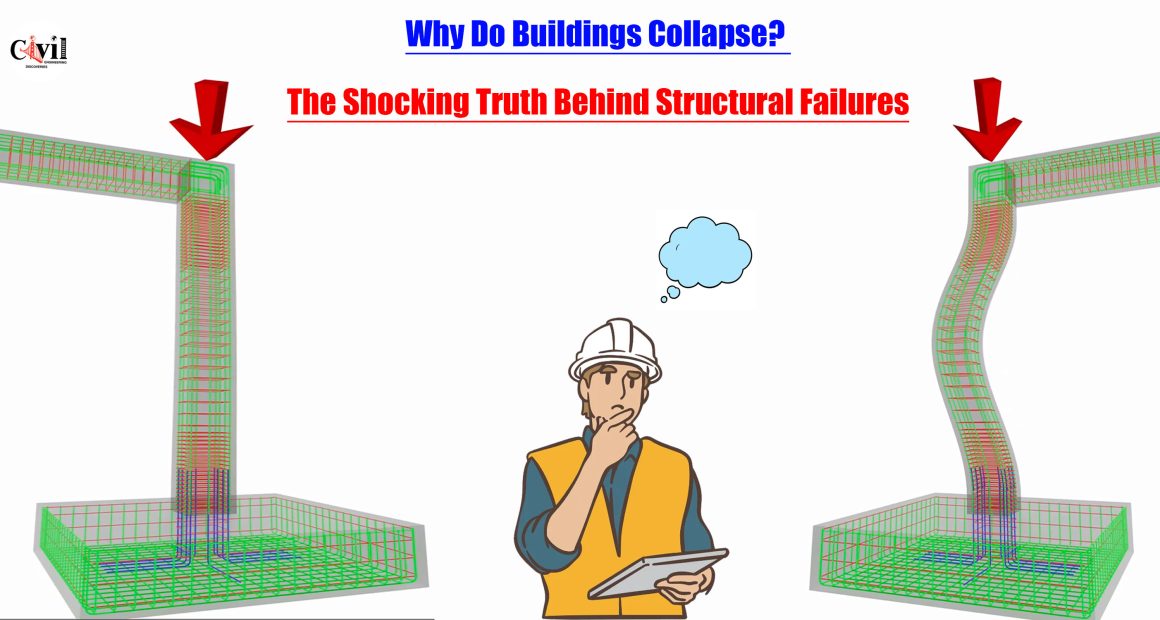

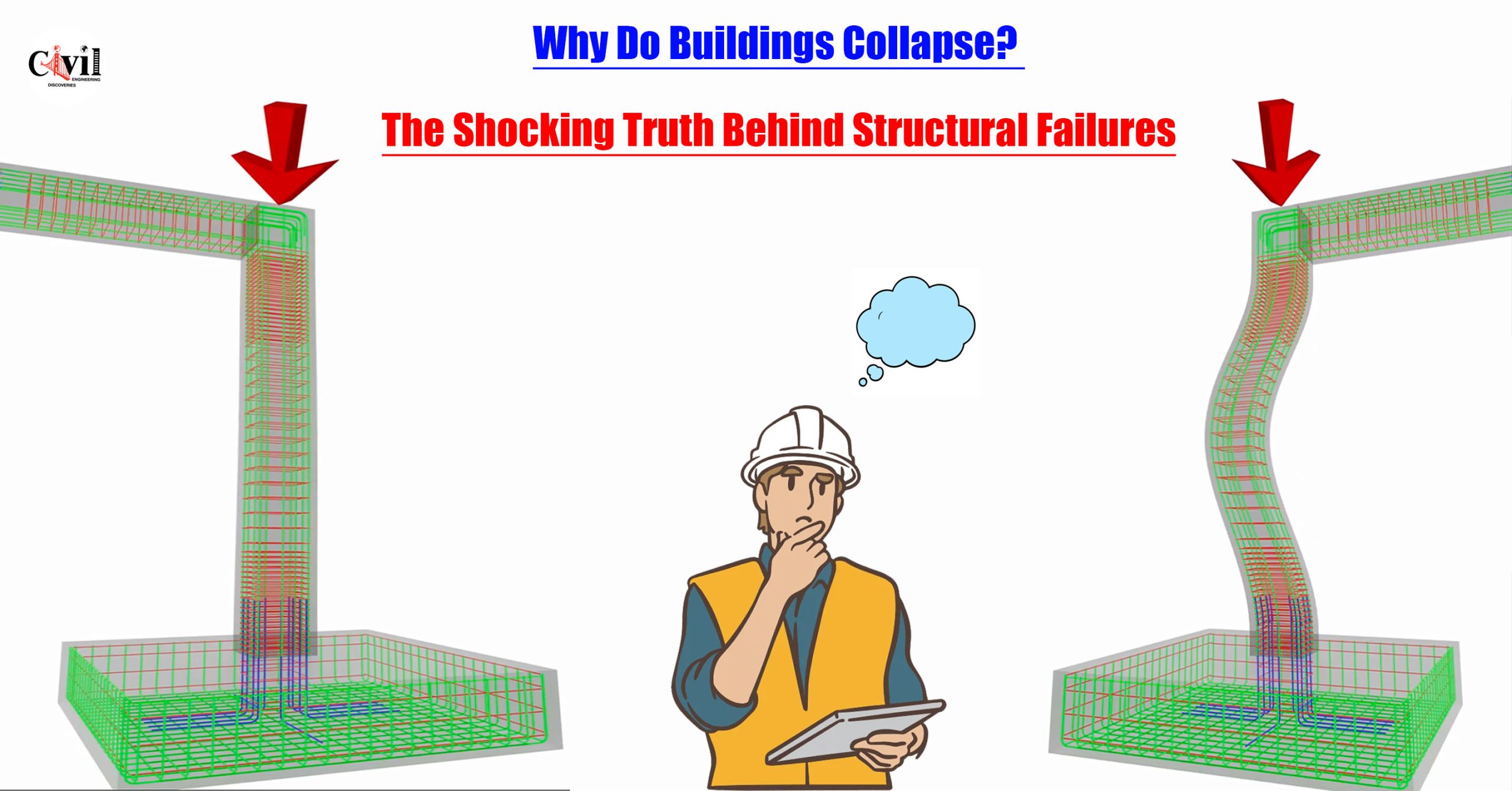

Buildings are designed to withstand various forces, including gravity, wind, and seismic activity. However, one of the most significant structural failures that can lead to a building collapse is column buckling. This phenomenon occurs when a column loses its stability due to excessive compressive loads, ultimately leading to catastrophic failure. In this article, we explore the causes, consequences, and prevention strategies associated with column buckling to ensure safe and stable building designs.

What Is Column Buckling?

Column buckling is a structural failure mode in which a slender column subjected to compressive forces deforms laterally and eventually collapses. Unlike crushing failure, which results from the material’s inability to withstand compression, buckling occurs due to instability in the column’s geometry. This is particularly common in long and thin columns, where lateral deflections compromise their load-bearing capacity.

Key Factors Influencing Column Buckling

Several factors determine the susceptibility of a column to buckling:

- Slenderness Ratio (L/r): The slenderness ratio, defined as the effective length (L) of the column divided by its radius of gyration (r), plays a critical role in buckling. The higher the slenderness ratio, the more prone the column is to buckling.

- Material Properties: The elasticity and strength of materials, such as steel and concrete, affect their resistance to buckling.

- Boundary Conditions: The way a column is supported at its ends significantly impacts its critical buckling load.

- Load Distribution: Uneven or eccentric loads can increase the risk of buckling by introducing bending stresses.

Types of Column Buckling

Buckling can occur in various forms, depending on the characteristics of the column and external conditions:

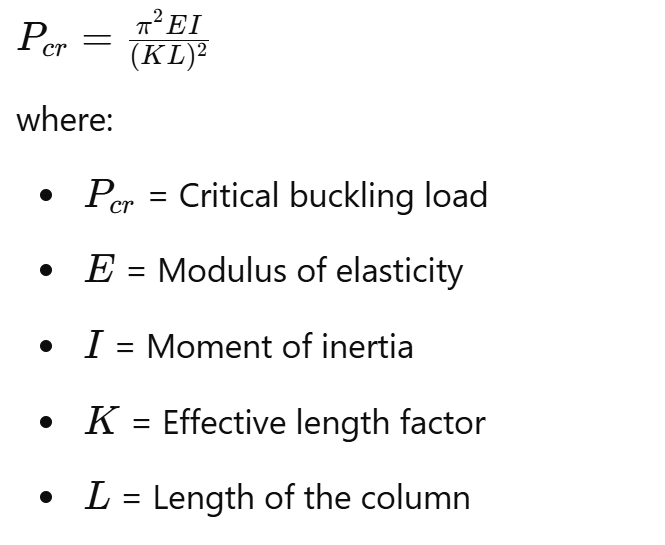

Elastic Buckling

This occurs in columns that remain within the elastic limit of the material but still fail due to instability. It is often analyzed using Euler’s critical load formula:

Inelastic Buckling

When a column reaches its yield strength before buckling, inelastic buckling occurs. This is common in shorter, stockier columns where material failure and instability occur simultaneously.

Local Buckling

This type of failure is observed in thin-walled columns, such as those made of steel plates or hollow sections, where certain regions of the column buckle independently of the entire structure.

Common Causes of Column Buckling in Buildings

1. Poor Structural Design

Inadequate design calculations, improper material selection, and incorrect assumptions about load conditions can lead to columns that are too slender or weak to withstand applied forces.

2. Overloading

Exceeding the designed load capacity of a column increases compressive stress, making it more susceptible to buckling. This often happens in buildings where additional floors are added without reinforcing existing columns.

3. Weak Foundation and Soil Settlement

A weak or shifting foundation can cause differential settlements, resulting in uneven load distribution on columns. This can lead to increased bending moments and premature buckling.

4. Construction Deficiencies

Poor workmanship, including improper reinforcement placement, inadequate curing of concrete, and misalignment of columns, can significantly reduce a column’s resistance to buckling.

5. Corrosion and Material Degradation

In steel and reinforced concrete columns, corrosion of steel reinforcements weakens the structural integrity, reducing load-bearing capacity and increasing the likelihood of buckling.

6. Seismic and Wind Loads

Lateral forces due to earthquakes or high winds can induce additional bending stresses in columns, increasing the probability of buckling failure.

Preventive Measures to Avoid Column Buckling

1. Optimized Structural Design

Engineers should consider the following strategies to design columns resistant to buckling:

- Reduce Slenderness Ratio: Using shorter and wider columns enhances stability.

- Select Appropriate Materials: High-strength steel and reinforced concrete provide better buckling resistance.

- Use Stiffeners: Stiffeners in steel structures help distribute stress and prevent local buckling.

2. Load Management

- Ensure that live and dead loads do not exceed design limits.

- Distribute loads evenly to avoid localized stress concentrations.

3. Strengthening Foundations

- Conduct proper soil testing to ensure stable ground conditions.

- Design foundations to minimize differential settlements.

4. Quality Construction Practices

- Ensure proper reinforcement placement and alignment during construction.

- Maintain strict quality control on material usage and installation.

5. Regular Maintenance and Inspections

- Periodic inspections can help identify early signs of corrosion, cracks, or deformation.

- Implement protective coatings on steel structures to prevent corrosion-related weakening.

6. Seismic and Wind Resistance Measures

- Use bracing systems to provide additional lateral support.

- Implement base isolation techniques to reduce seismic forces.