In civil construction, reinforcement bars (rebar) are pivotal in providing tensile strength to concrete structures. Among various available shapes, circular (round) reinforcement bars are universally adopted due to their superior mechanical, structural, and practical advantages. In this comprehensive article, we delve into the reasons why reinforcement steel bars are made round in shape, highlighting their relevance, efficiency, and indispensability in modern construction.

What Are Reinforcement Bars and Their Function in Concrete?

Concrete is inherently strong in compression but weak in tension. Reinforcement bars are embedded within concrete to absorb tensile stresses, enhancing structural durability and preventing cracking under load. The union of concrete and steel creates reinforced concrete, a composite material capable of withstanding both compressive and tensile forces, crucial for buildings, bridges, dams, and highways.

Engineering Rationale Behind the Circular Cross-Section

1. Uniform Stress Distribution

The circular cross-section of reinforcement bars allows uniform stress distribution when subjected to tensile forces. This geometry ensures that no specific axis or side bears a disproportionate amount of stress, which could otherwise lead to premature failure or structural inefficiency.

2. Superior Bonding With Concrete

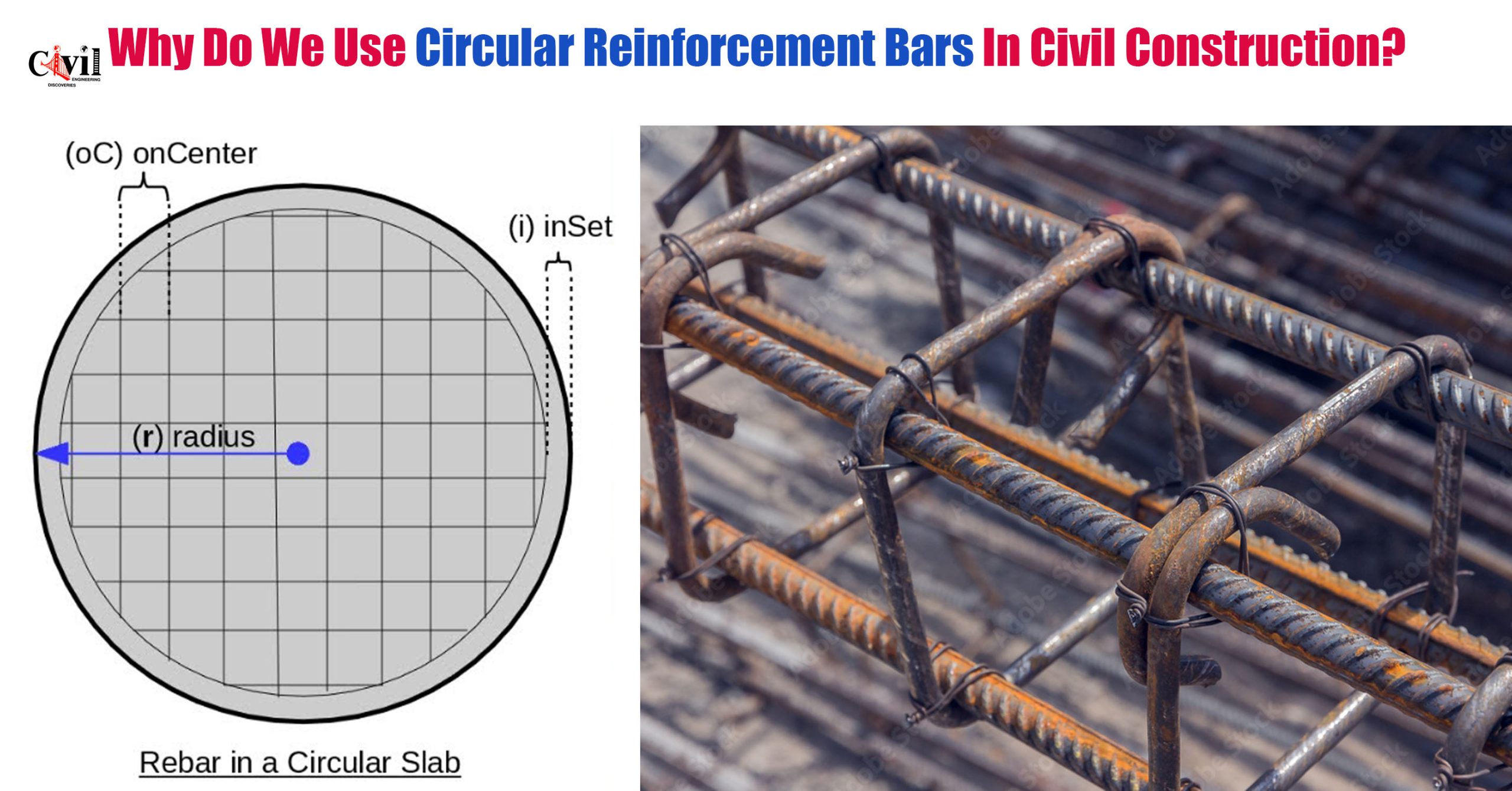

Bond strength is the adhesion between concrete and steel. Round bars provide optimal surface contact area with the surrounding concrete. Combined with surface deformations (ribs or corrugations), this allows for maximum mechanical interlocking, improving load transfer and minimizing slippage under stress conditions.

Manufacturing and Material Science Benefits

1. Efficient Rolling Process

From a manufacturing perspective, hot rolling is the most common method of producing reinforcement bars. Rolling steel into a circular section is simpler, faster, and more economical compared to other shapes. The symmetrical form allows for even deformation during the rolling process, resulting in uniform mechanical properties throughout the length.

2. Material Economy

A circular shape requires less surface area to enclose the same volume as other geometries like square or hexagonal. This means less material is needed to achieve the same mechanical performance, leading to cost savings and efficient resource utilization during large-scale production.

Ease of Handling and Construction Practicality

1. Easy Bending and Cutting

On construction sites, rebar is often required to be bent into specific shapes. Round bars can be bent more easily and precisely without fracturing, maintaining structural integrity. Square or angular bars would concentrate stresses at the corners during bending, increasing the crack initiation and failure.

2. Reduced Injury Risk for Workers

Handling sharp-edged bars like square or flat steel sections can cause injuries to workers. The rounded edges of circular rebars reduce the risk of cuts and abrasions, enhancing safety during manual handling and placement.

Compatibility With Design and Codes

1. Compliance With International Standards

Most international construction standards and codes such as ASTM A615, BS 4449, IS 1786, and Eurocode specify circular cross-section as the standard shape for reinforcement bars. This ensures global consistency in structural design, quality control, and engineering practice.

2. Ease of Structural Modeling and Analysis

Circular bars are easier to model using structural analysis software and design tools. Calculations involving bending, shear, and tensile stress are more accurate and simplified when working with circular geometries, allowing engineers to ensure safety with better efficiency.

Enhanced Corrosion Resistance

1. Even Coating During Galvanization

When corrosion-resistant coatings such as zinc are applied to rebar, circular bars receive an even and uniform layer due to their symmetrical profile. This provides consistent protection against environmental factors such as moisture, salts, and industrial pollutants.

2. Less Stress Concentration

Flat or angular surfaces typically lead to stress concentrations at edges or corners, which can become initiation points for rust and corrosion. Round bars, with their smooth and continuous surface, minimize such vulnerabilities, extending the lifespan of the reinforcement.

Hydraulic and Dynamic Load Performance

In certain applications such as bridge decks or high-rise structures, reinforcement may be subjected to cyclic or dynamic loading. Circular bars, due to their uniform shape and mass distribution, perform more predictably under fatigue conditions, enhancing durability under variable load patterns.

Adaptability in Reinforcement Arrangement

1. Better Concrete Flow During Pouring

Circular rebars allow easier flow of concrete around the reinforcement cage. This reduces the likelihood of voids or honeycombing, ensuring that the concrete fully encapsulates the reinforcement, which is vital for long-term strength and durability.

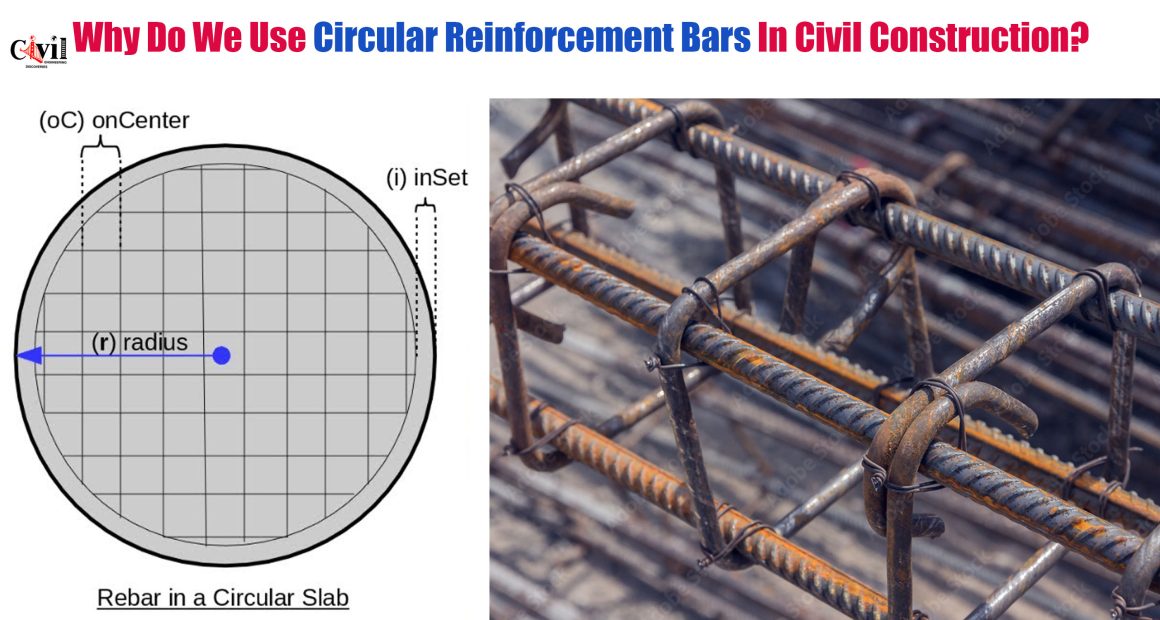

2. Simplified Spacing and Lapping

In reinforced concrete detailing, lap splices and bar spacing are critical design elements. Round bars simplify these calculations and ensure efficient space utilization, maintaining code-specified cover and improving constructability in congested zones.

Limitations of Non-Circular Reinforcement Bars

1. Poor Bonding and Workability

Non-circular bars like square or rectangular ones may lack proper bonding characteristics. Their sharp corners can cause stress risers and poor workability during placement.

2. Incompatibility With Current Construction Norms

Modern reinforcement detailing practices, equipment, and software are optimized for round bars. Introducing non-circular bars would require re-engineering existing processes and tools, leading to inefficiencies and increased costs.

Conclusion: Circular Bars as the Ideal Reinforcement Shape

The dominance of circular reinforcement bars in civil construction is neither accidental nor arbitrary. It stems from a rich interplay of structural mechanics, material science, safety, practicality, and economic viability. Their symmetrical design ensures uniform load distribution, excellent bond with concrete, ease of manufacturing, and seamless integration into modern construction practices.

Adopting alternative shapes would introduce more problems than benefits, requiring compromises in structural safety, increased costs, and deviations from established international standards.

Therefore, in the pursuit of safe, efficient, and durable civil infrastructure, the circular rebar remains an irreplaceable cornerstone in reinforced concrete technology.

Click Here To See Why Steel Are Binds By Binding Wire? Purpose Of Binding Wire

THE CIRCULAR IS MOST APPROPIATED IN THE RE-INFORCEMENT OF THE COLUMN AND BEANS OF THE STRUCTURE TO BE ERECTED. FURTHER MORE IT HAS MORE STEELS AND TIRE ROD ON THEM FOR THE BALANCING OF WEIGHT AND THE FORCE OF GRAVITY ON THEM TO THE EARTH