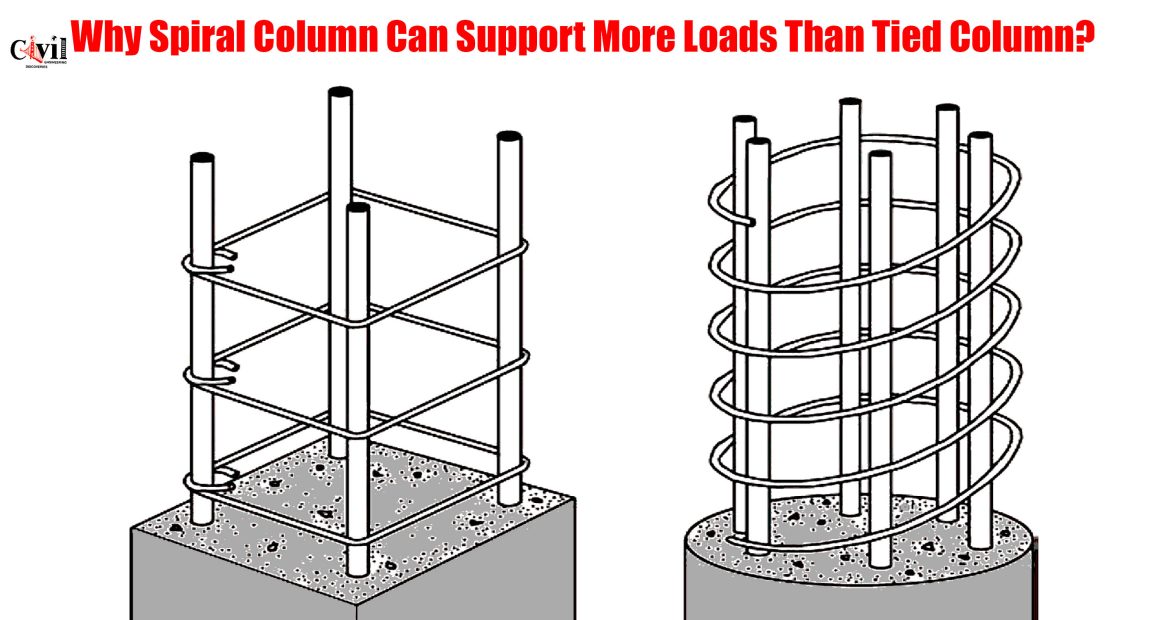

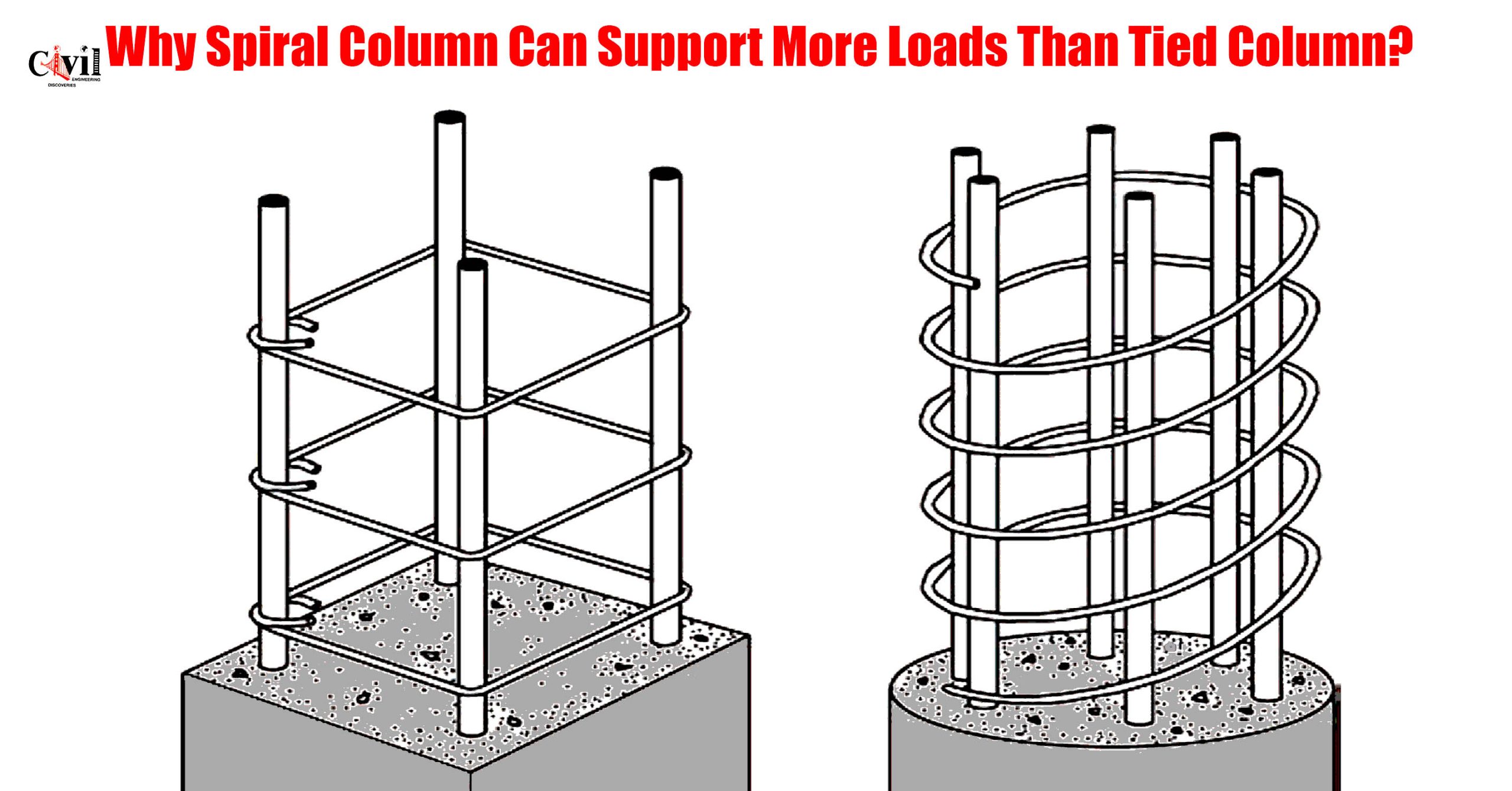

Spiral columns, also known as helical columns, are known for their ability to support greater loads compared to tied columns due to several reasons:

- Increased Strength: The spiral reinforcement wraps around the column, providing more surface area for the concrete to bond to. This increased bond between the concrete and the spiral reinforcement enhances the column’s strength and load-bearing capacity.

- Improved Ductility: Spiral reinforcement provides better ductility, allowing the column to undergo larger deformations before failure. This means that even under heavy loads or in seismic events, spiral columns are more likely to maintain their structural integrity.

- Enhanced Confinement: The spiral reinforcement provides confinement to the concrete core, which helps in preventing premature failure due to buckling or crushing of the concrete under high compressive loads. This confinement effect contributes significantly to the column’s load-carrying capacity.

- Reduced Risk of Buckling: The continuous spiral reinforcement helps distribute the load evenly along the length of the column, reducing the risk of buckling compared to tied columns, where the ties may concentrate stresses at specific points.

- Better Performance in Earthquakes: Spiral columns are preferred in seismic zones because of their enhanced ductility and confinement properties. They can better withstand the lateral forces and deformations experienced during earthquakes compared to tied columns.

Overall, the combination of increased strength, improved ductility, enhanced confinement, and reduced risk of buckling makes spiral columns capable of supporting more loads compared to tied columns, especially in high-rise buildings and seismic regions.

However, it’s important to note that the choice between spiral and tied columns depends on various factors such as the specific requirements of the project, cost considerations, and the availability of skilled workers and special equipment.

Click Here To See Flexible Pavement Layers In Road Construction