In Reinforced Cement Concrete (RCC), steel reinforcement is essential. Yet, its volume is not deducted when calculating the total concrete volume. Why?

Steel accounts for only 1% to 3% of the total concrete volume in typical RCC structures. This small percentage is considered negligible during volume estimations.

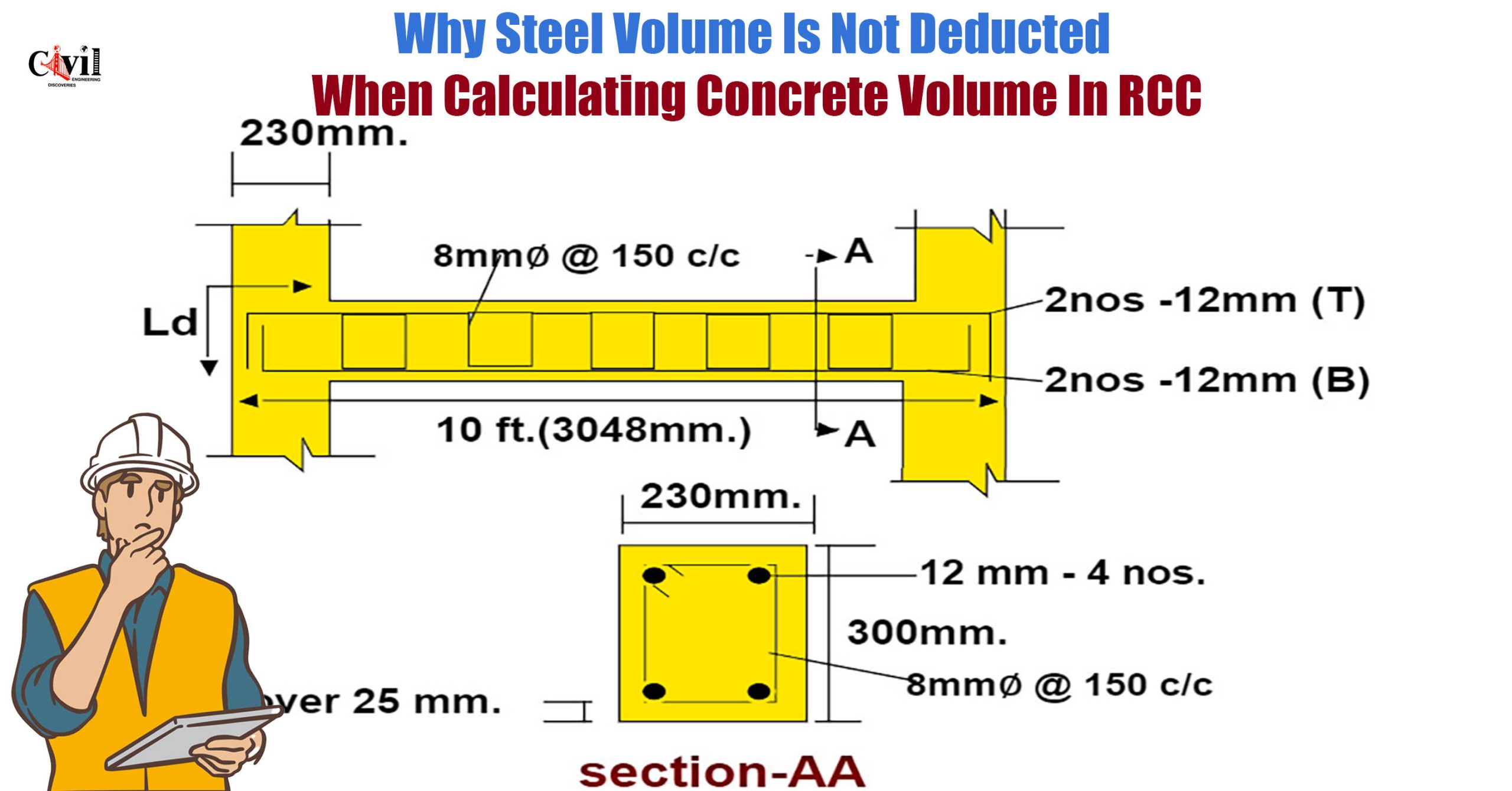

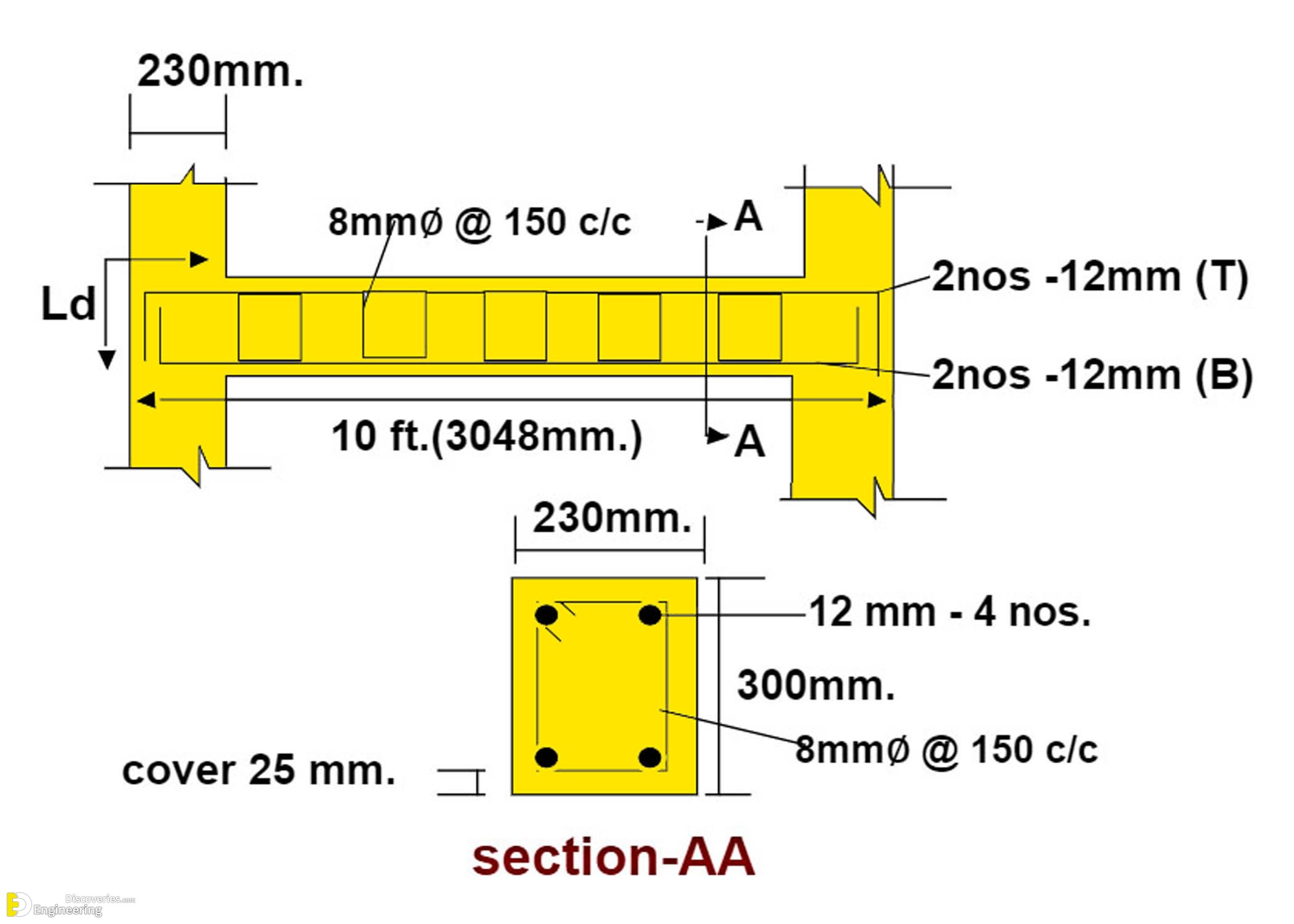

Let’s break it down using a simple beam example.

Concrete Volume Calculation in RCC Beam

Formula:

Volume of Concrete = Length × Breadth × Height

Example:

Let’s take a beam with the following dimensions:

Clear length: 3.048 m

Two supports: 0.230 m each

Width (B): 0.23 m

Height (H): 0.3 m

Concrete Volume:

= (3.048 m – 2 × 0.230 m) × 0.23 m × 0.3 m

= 2.588 m × 0.23 m × 0.3 m

= 0.178 m³

Steel Volume Calculation in the Beam

Main Bars:

4 bars

Diameter = 12 mm = 0.012 m

Volume of Main Bars:

= 4 × 0.7855 × d² × L

= 4 × 0.7855 × (0.012²) × 3.048

= 0.00137 m³

Lateral Ties:

19 ties

Diameter = assumed to be the same

Length = 1.124 m

Volume of Ties:

= 19 × 0.7855 × d² × L

= 19 × 0.7855 × (0.012²) × 1.124

= 0.001 m³

Total Steel Volume:

= 0.00137 + 0.001

= 0.00237 m³

Steel Volume Percentage in RCC

To calculate the percentage of steel in the total RCC volume:

= (Steel Volume ÷ Concrete Volume) × 100

= (0.00237 ÷ 0.178) × 100

= 1.33%

Concrete occupies 98.67%, while steel occupies only 1.33% of the total volume.

Why Steel Volume Is Ignored in Concrete Calculation

Steel’s contribution is minimal. When casting RCC, concrete wastage usually exceeds the volume of steel. This makes it practical to ignore steel volume in calculations.

Instead of making complex adjustments for a small steel portion, builders accept this margin as part of overall wastage.

Concrete Wastage During Casting – Key Reasons

1. Bulging of Formwork

During compaction using vibrators, formwork may slightly expand. This adds volume, and more concrete fills the space.

2. Leveling Challenges

Achieving a perfect top level of concrete is hard. Workers often pour a bit more to ensure coverage and avoid underfilling.

3. Spillage During Pouring

Concrete often spills over the sides of formwork or onto the ground. This is especially common when pouring from height or using trolleys.

4. Equipment Adhesion Loss

Concrete sticks to mixers, trolleys, vibrators, and tools. The leftover material adds up and contributes to the total wastage.

Click Here To See How To Calculate The Total Load Over The RCC Beam