In the ever-evolving world of construction and civil engineering, selecting the right type of cement is crucial for ensuring structural integrity, durability, and efficiency. Civil engineers must be well-versed in the various types of cement available in the market to make informed choices depending on the project requirements, environmental exposure, and desired performance characteristics. Here, we explore in detail the 10 most essential types of cement that every civil engineer should master for successful project execution.

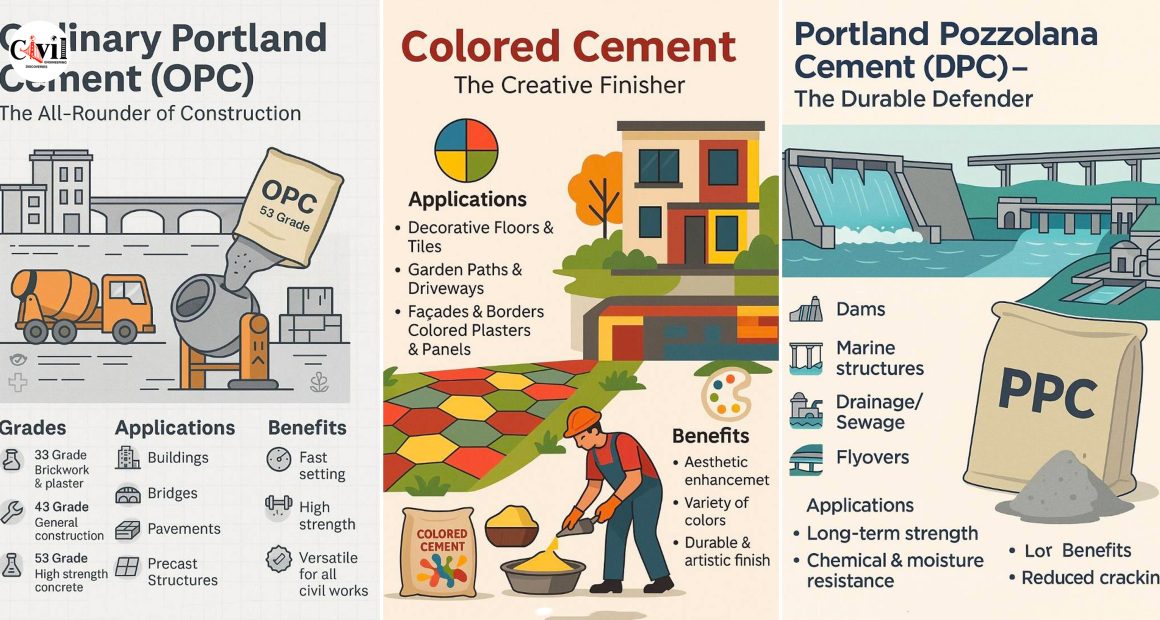

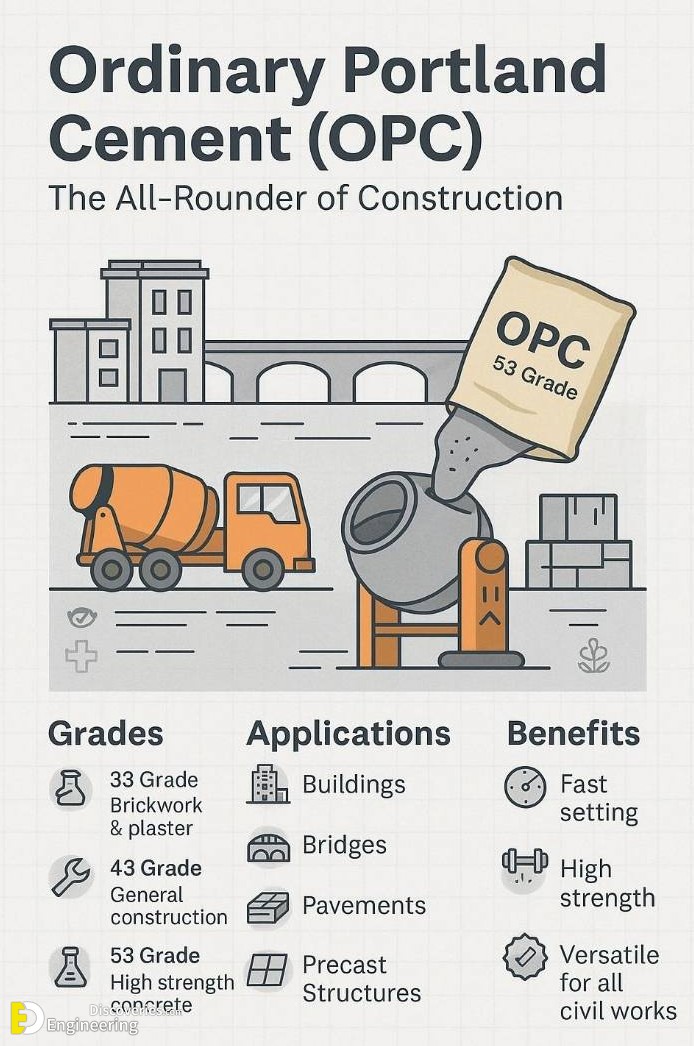

1. Ordinary Portland Cement (OPC): The All-Rounder of Construction

Ordinary Portland Cement (OPC) is the most widely used type of cement and serves as the foundation for countless civil structures. Available in 33, 43, and 53 grades, OPC is ideal for a range of applications:

Applications:

Residential and commercial buildings

Bridges and flyovers

Road pavements

Precast concrete products

Benefits:

Fast setting time

High strength gain

Versatile for all types of civil works

Whether you’re constructing high-rise buildings or rural homes, OPC remains the go-to cement for its balanced performance and availability.

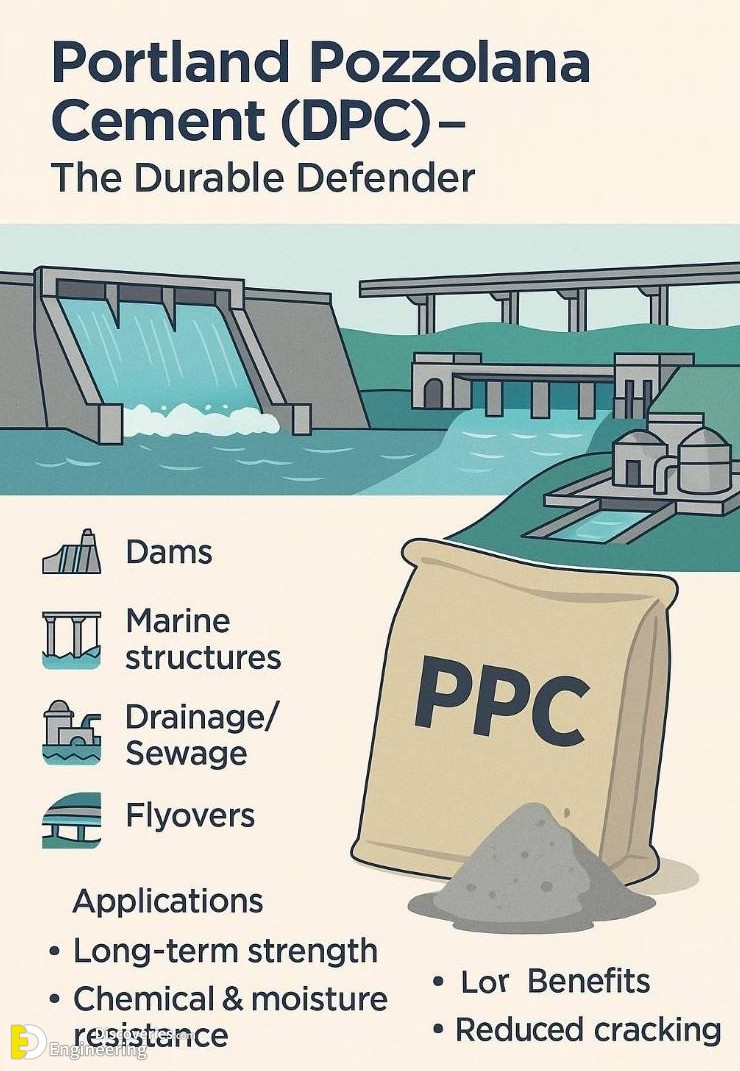

2. Portland Pozzolana Cement (PPC): The Durable Defender

Portland Pozzolana Cement (PPC) is made by blending pozzolanic materials such as fly ash with OPC. It is highly favored for its resistance to chemical attacks and long-term strength development.

Applications:

Dams and marine structures

Drainage and sewage systems

Bridges and flyovers

Benefits:

Reduced thermal cracking

Increased durability

Cost-effective for large projects

Civil engineers prefer PPC in environments where moisture and chemicals can degrade ordinary concrete over time.

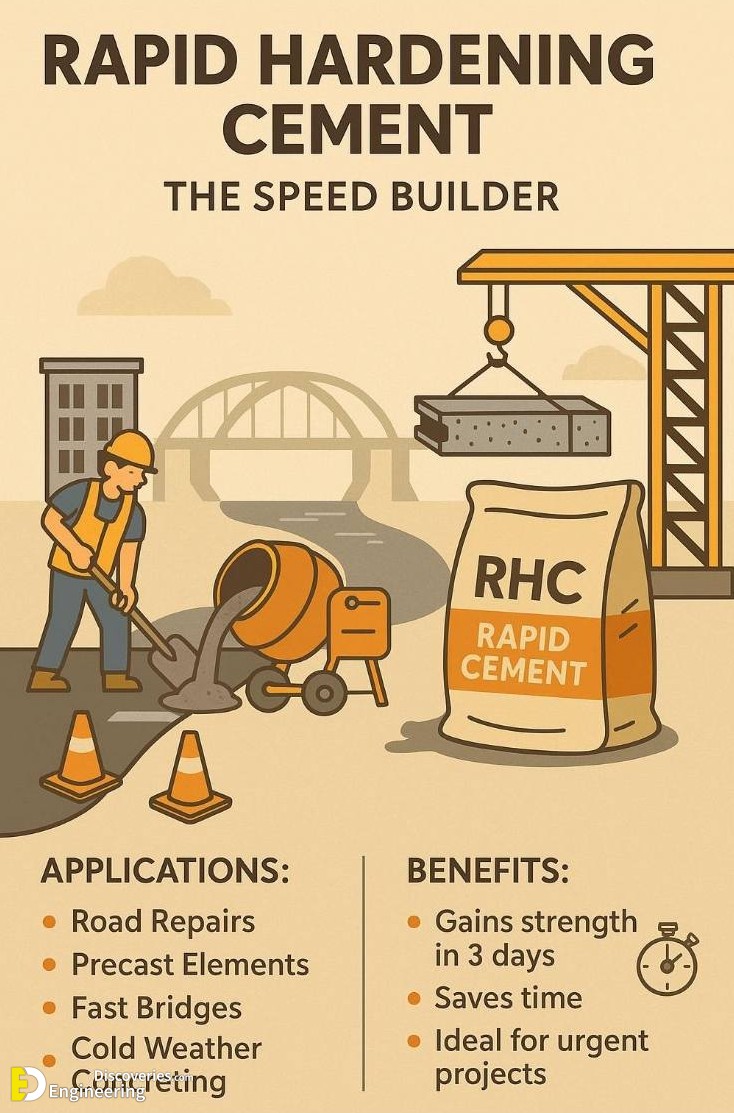

3. Rapid Hardening Cement (RHC): The Speed Builder

When time is of the essence, Rapid Hardening Cement (RHC) offers the solution. This type of cement develops strength quickly, often within 3 days, making it perfect for fast-track projects.

Applications:

Road repairs

Precast concrete elements

Cold weather concreting

Benefits:

Accelerated construction timeline

Saves time and labor costs

Useful in critical infrastructure repair

Its fast strength development is especially useful in urban environments where downtime must be minimized.

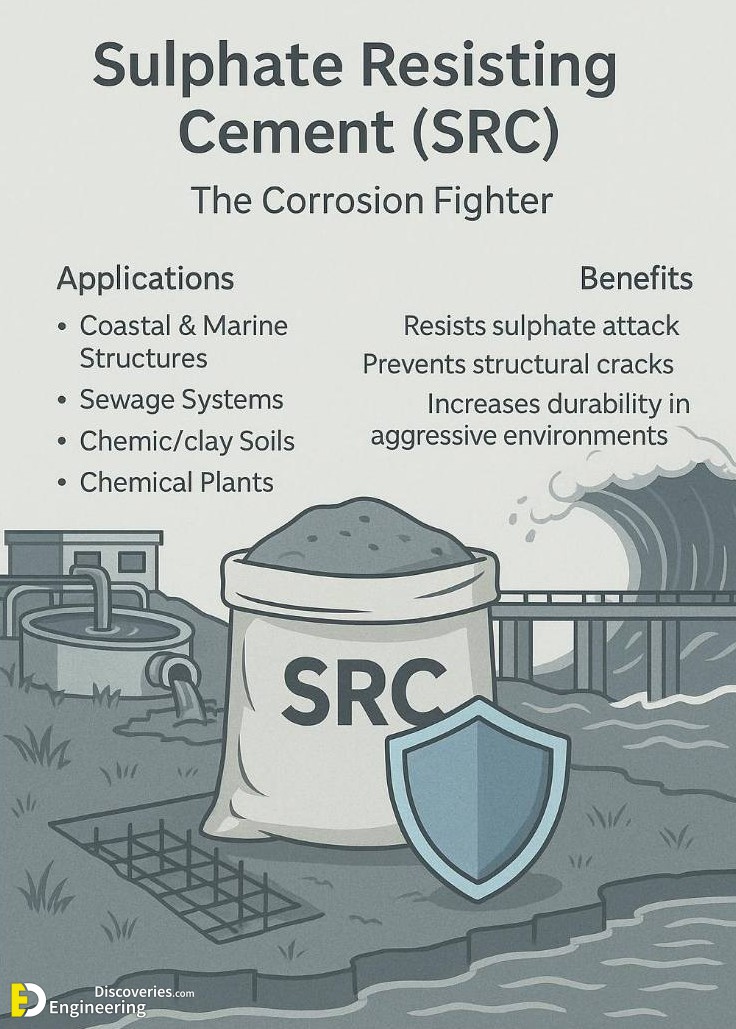

4. Sulphate Resisting Cement (SRC): The Corrosion Fighter

Sulphate Resisting Cement (SRC) is specially formulated to resist sulphate attacks in aggressive environments.

Applications:

Coastal and marine construction

Sewage treatment and drainage systems

Chemical and fertilizer plants

Benefits:

Improved durability in hostile environments

Prevents sulphate-induced cracks

Extends structure lifespan

SRC is essential for use in sub-grade structures that come into contact with sulphate-rich soils and water.

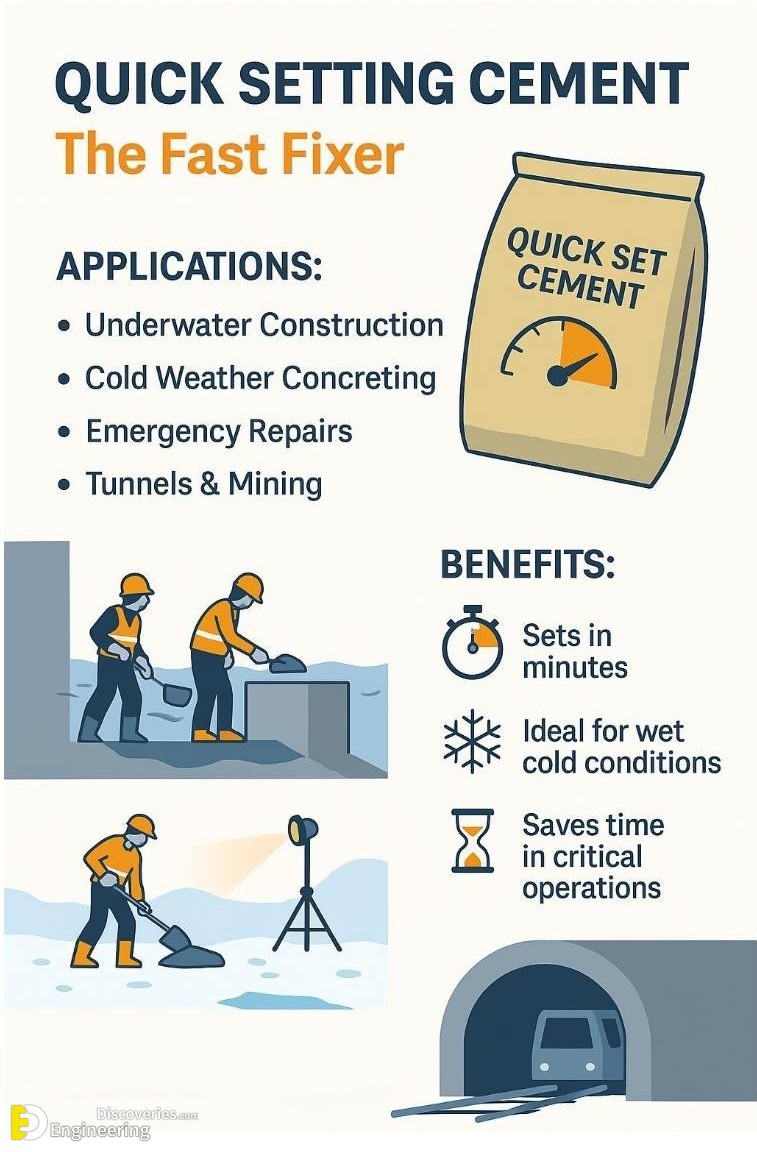

5. Quick Setting Cement: The Fast Fixer

Quick-setting cement is known for its exceptionally short setting time, making it indispensable in emergencies.

Applications:

Underwater construction

Tunnels and mines

Cold weather concreting

Emergency repairs

Benefits:

Sets in minutes

Ideal for wet and cold conditions

Time-saving in critical operations

Quick-setting cement is a must-have in a civil engineer’s arsenal for urgent construction scenarios.

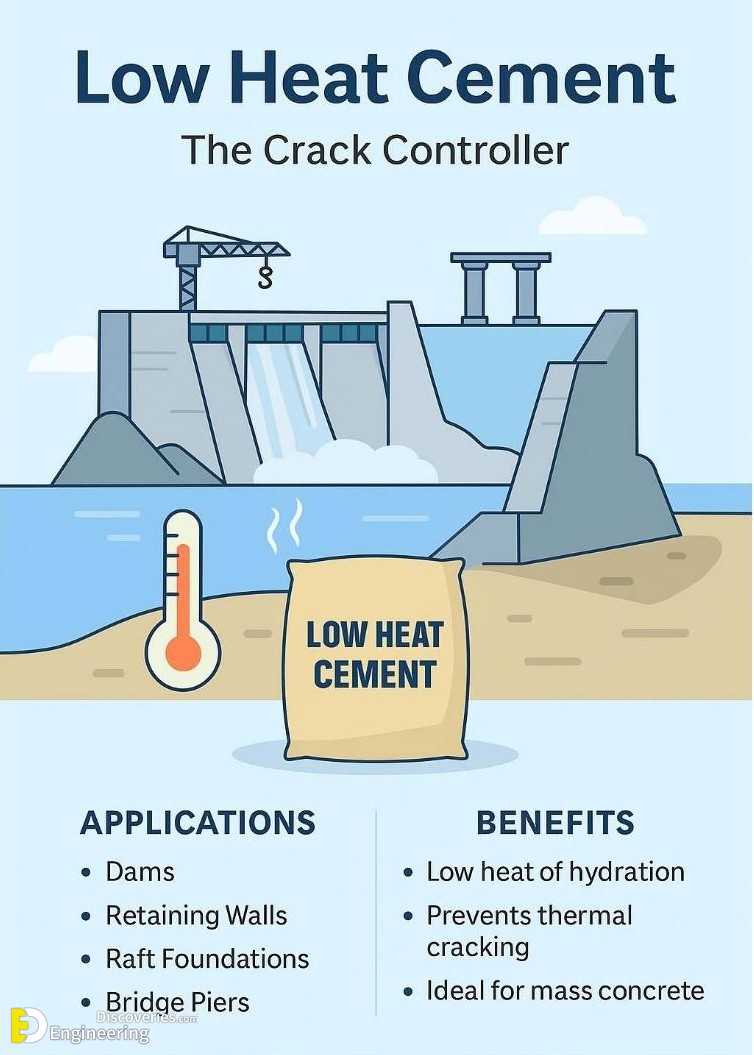

6. Low Heat Cement: The Crack Controller

Designed to reduce the heat of hydration, Low Heat Cement is ideal for mass concrete works where controlling internal temperature is vital.

Applications:

Dams

Bridge piers

Retaining walls

Raft foundations

Benefits:

Minimizes thermal cracks

Sustains structural integrity

Best suited for large volume pours

This cement is essential for preventing structural cracking in large infrastructure projects.

7. White Cement: The Aesthetic Artist

White Cement is prized for its aesthetic appeal and is used where visual appearance is as important as structural performance.

Applications:

Architectural designs

Decorative floors and tiles

Sculptures and artistic works

Benefits:

Bright, smooth finish

Superior blending with pigments

Ideal for luxury interiors and exteriors

White Cement elevates the visual quality of structures while maintaining durability.

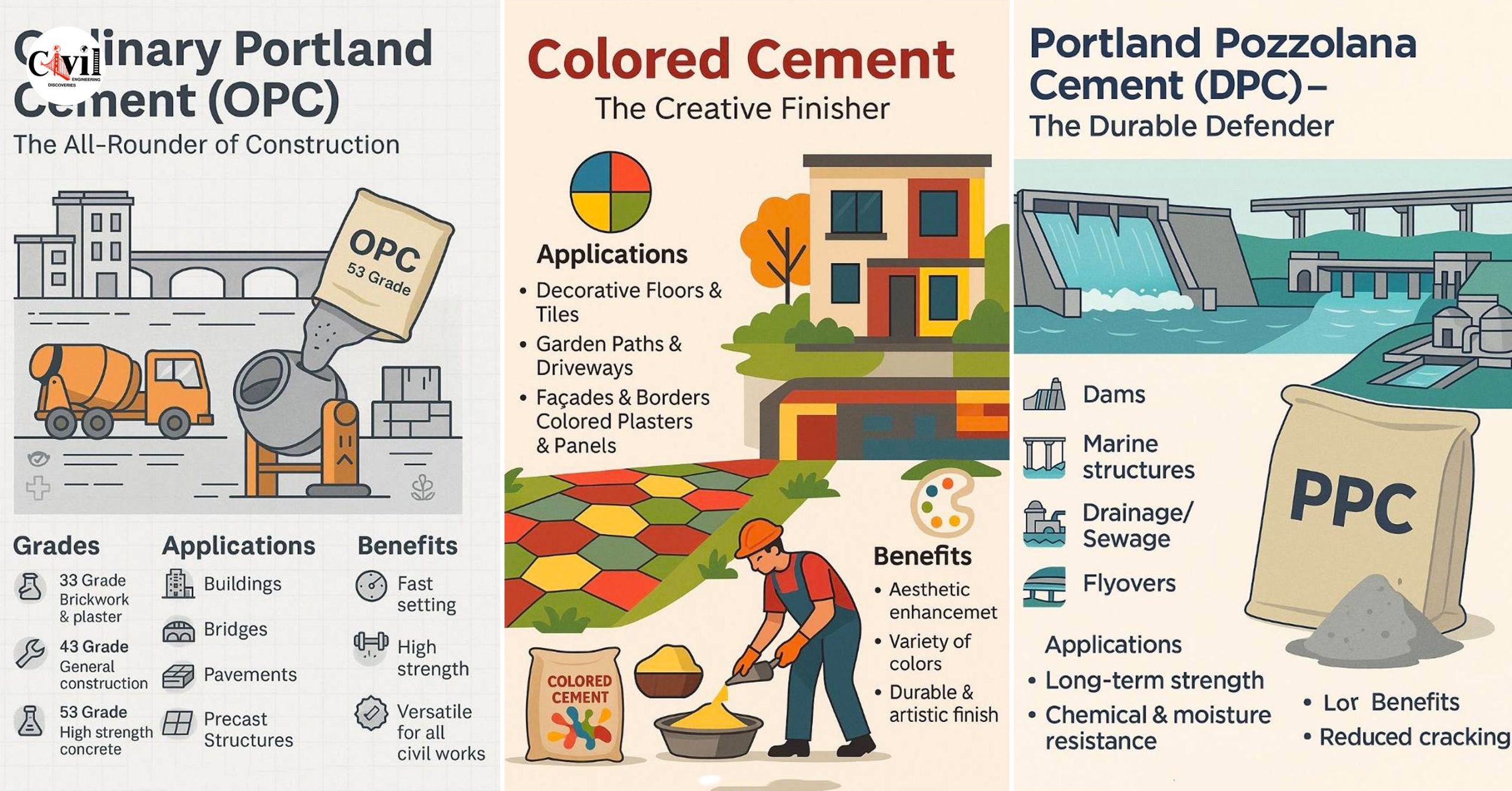

8. Colored Cement: The Creative Finisher

Colored Cement is ordinary cement blended with mineral pigments to achieve a variety of hues.

Applications:

Pavements and walkways

Garden paths

Façades and walls

Tiles and panels

Benefits:

Aesthetic enhancement

Available in diverse colors

Maintains durability and finish

This type of cement is popular in landscaping and urban beautification projects.

9. High Alumina Cement: The Heat Warrior

High Alumina Cement contains a high percentage of aluminum oxide, giving it remarkable resistance to high temperatures and chemical attacks.

Applications:

Kilns and furnaces

Marine and sewage works

Chemical processing plants

Benefits:

Rapid strength development

Withstands extreme temperatures

Corrosion-resistant

It is the preferred choice for industrial construction in extreme environments.

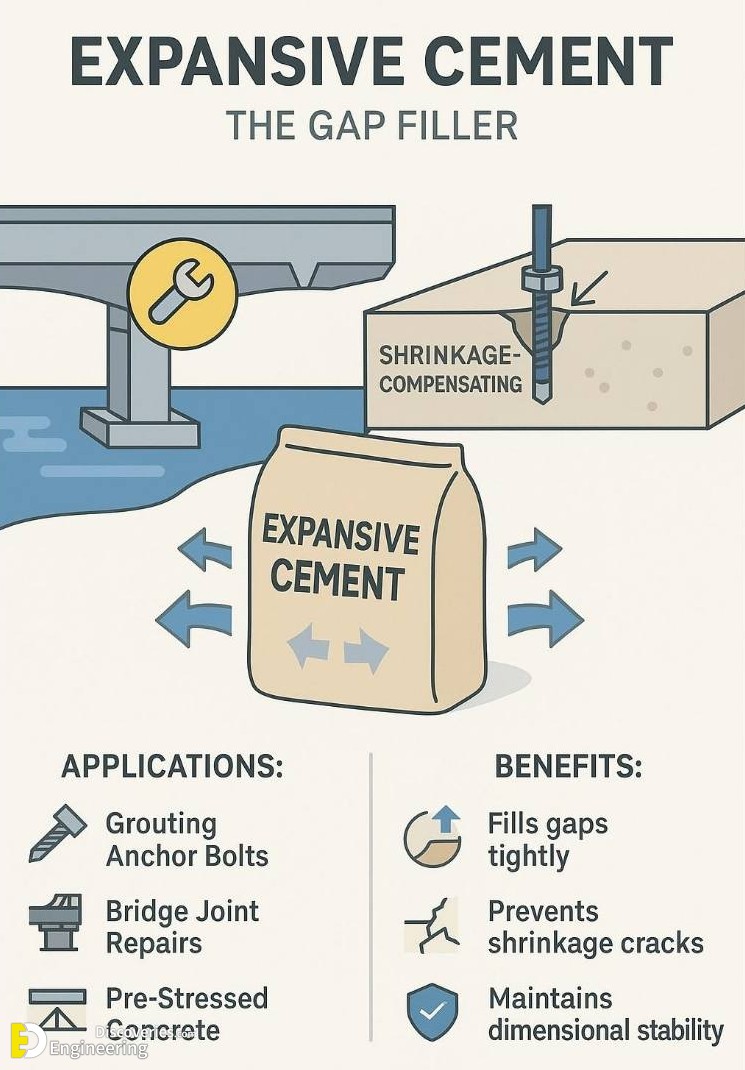

10. Expansive Cement: The Gap Filler

Expansive Cement is specially formulated to compensate for shrinkage and prevent cracking during hardening.

Applications:

Grouting and anchoring

Bridge joint repairs

Pre-stressed concrete

Benefits:

Fills gaps effectively

Prevents shrinkage cracks

Maintains dimensional stability

It is beneficial in precision structural repairs and retrofits.

Conclusion

Every civil engineer must understand various cement types’ unique properties and applications to ensure project success. Whether the goal is aesthetic appeal, rapid construction, or long-term durability, a cement is tailored for every need. The ability to choose the right cement is not just technical — it’s strategic, influencing both project efficiency and structural resilience.

Click Here To See How To Calculate The Quantity Of Cement, Sand, And Bricks For 1 Cubic Meter

Very easy to understand. Thanks very much