Properly designed and maintained HMA pavements can provide many years of satisfactory service. However, like all pavements, HMA pavements can be damaged by certain conditions. This article is intended to:

- Assist in identifying basic HMA pavement damage. HMA pavement damage that is visible at the surface of the pavement is often called “surface distress”.

- Provide some insight into why particular surface distresses are problematic.

- Provide some basic guidance into what kinds of conditions might lead to certain surface distresses.

- Suggest some basic repair strategies.

1- Alligator (Fatigue) Cracking

Description: A series of interconnected cracks caused by fatigue failure of the HMA surface under repeated traffic loading. As the number and magnitude of loads become too great, longitudinal cracks begin to form (usually in the wheel paths). After repeated loading, these longitudinal cracks connect forming many-sided sharp-angled pieces that develop into a pattern resembling the back of an alligator or crocodile.

Problem: Roughness, indicators of structural failure, cracks allow moisture infiltration into the base and subgrade, eventually results in potholes and pavement disintegration if not treated.

Possible Causes: Inadequate structural support for the given loading, which can be caused by a myriad of things. A few of the more common ones are:

1- Decrease in pavement load supporting characteristics.

- Probably the most common reason is a loss of base, subbase or subgrade support from poor drainage. Water under a pavement will generally cause the underlying materials to become weak.

- Stripping on the bottom of the HMA layer. The stripped depth contributes little to pavement strength so the effective HMA thickness decreases.

2- Increase in loading (i.e., the pavement is being loaded more heavily than anticipated in the design)

3- Inadequate structural design (i.e., the pavement was designed too thin for the anticipated loads)

4- Poor construction (i.e., inadequate compaction)

Repair: A fatigue cracked pavement should be investigated to determine the root cause of failure. Any investigation should involve digging a pit or coring the pavement to determine the pavement’s structural makeup as well as determining whether or not subsurface moisture is a contributing factor. Once the characteristic alligator pattern is apparent, repair by crack sealing is generally ineffective. Fatigue crack repair generally falls into one of two categories:

- Small, localized fatigue cracking indicative of a loss of subgrade support. Remove the cracked pavement area, then dig out and replace the area of poor subgrade and improve the drainage of that area if necessary. Patch over the repaired subgrade.

- Large fatigue cracked areas indicative of general structural failure. Place an HMA overlay over the entire pavement surface. This overlay must be strong enough structured to carry the anticipated loading because the underlying fatigue cracked pavement most likely contributes little or no strength

2- Bleeding

Description: A film of asphalt binder on the pavement surface. It usually creates a shiny, glass-like reflecting surface that can become sticky when dry and slippery when wet.

Problem: Loss of skid resistance when wet, unsightly

Possible Causes: Bleeding occurs when asphalt binder fills the aggregate voids during hot weather or traffic compaction, and then expands onto the pavement surface. Since bleeding is not reversible during cold weather or periods of low loading, asphalt binder will accumulate on the pavement surface over time. Likely causes are:

- Excessive asphalt binder in the HMA (either due to a poor mix design or manufacturing problems)

- Excessive application of asphalt binder during BST application

- Low HMA air void content (e.g., not enough void space for the asphalt to occupy), likely a mix design problem

Repair: The following repair measures may eliminate or reduce the asphalt binder film on the pavement’s surface, but may not correct the underlying problem that caused the bleeding:

- Minor bleeding can often be corrected by applying coarse sand to blot up the excess asphalt binder.

- Major bleeding can be corrected by cutting off the excess asphalt with a motor grader or removing it with a heater planer. If the resulting surface is excessively rough, resurfacing may be necessary (APAI, no date given).

3- Block Cracking

Description: Interconnected cracks that divide the pavement up into rectangular pieces. Blocks range in size from approximately 1 ft2 To 100 ft2. Larger blocks are generally classified as longitudinal and transverse cracking. Block cracks normally occurs over a large portion of pavement area, but sometimes will occur only in non-traffic areas.

Problem: Allows moisture infiltration, roughness

Possible Causes: HMA shrinkage and daily temperature cycling. Typically caused by an inability of asphalt binder to expand and contract with temperature cycles because of:

- Asphalt binder aging

- Poor choice of asphalt binder in the mix design

Repair: Strategies depend upon the severity and extent of the block cracking:

- Low severity cracks (< 1/2 inch wide). Crack seal to prevent (1) entry of moisture into the subgrade through the cracks and (2) further raveling of the crack edges. HMA can provide years of satisfactory service after developing small cracks if they are kept sealed, slurry seal can be placed over the sealed cracks.

- High severity cracks (> 1/2 inch wide and cracks with raveled edges). Remove and replace the cracked pavement layer with an overlay.

4- Corrugation and Shoving

Description: A form of plastic movement typified by ripples (corrugation) or an abrupt wave (shoving) across the pavement surface. The distortion is perpendicular to the traffic direction. Usually occurs at points where traffic starts and stops (corrugation) or areas where HMA abuts a rigid object (shoving).

Problem: Roughness

Possible Causes: Usually caused by traffic action (starting and stopping) combined with:

- An unstable (i.e. Low stiffness) HMA layer (caused by mix contamination, poor mix design, poor HMA manufacturing, or lack of aeration of liquid asphalt emulsions)

- Excessive moisture in the subgrade

Repair: A heavily corrugated or shoved pavement should be investigated to determine the root cause of failure. Repair strategies generally fall into one of two categories:

- Small, localized areas of the corrugation or shoving. Remove the distorted pavement and patch.

- Large corrugated or shaved areas indicative of general HMA failure. Remove the damaged pavement and overlay.

5- Depression

Description: Localized pavement surface areas with slightly lower elevations than the surrounding pavement. Depressions are very noticeable after a rain when they fill with water.

Problem: Roughness, depressions filled with substantial water can cause vehicle hydroplaning

Possible Causes: Subgrade settlement resulting from inadequate compaction during construction.

Repair: By definition, depressions are small localized areas. A pavement depression should be investigated to determine the root cause of failure. Depressions should be repaired by removing the affected pavement, then digging out and replacing the area of poor subgrade. Patch over the repaired subgrade.

6- Joint Reflection Cracking

Description: Cracks in a flexible overlay of a rigid pavement. The cracks occur directly over the underlying rigid pavement joints. Joint reflection cracking does not include reflection cracks that occur away from an underlying joint or from any other type of base (e.g., cement or lime stabilized).

Problem: Allows moisture infiltration, roughness

Possible Causes: Movement of the rigid pavement slab beneath the HMA surface because of thermal and moisture changes. Generally not a load is initiated, however loading can hasten deterioration.

Repair: Strategies depend upon the severity and extent of the cracking:

- Low severity cracks (< 1/2 inch wide and infrequent cracks). Crack seal to prevent (1) entry of moisture into the subgrade through the cracks and (2) further raveling of the crack edges. In general, rigid pavement joints will eventually reflect through an HMA overlay without proper surface preparation.

- High severity cracks (> 1/2 inch wide and numerous cracks). Remove and replace the cracked pavement layer with an overlay after proper preparation of the underlying rigid pavement.

7- Longitudinal Cracking

Description: Cracks parallel to the pavement centerline or lay down direction. Usually a type of fatigue cracking.

Problem: Allows moisture infiltration, roughness, indicates the possible onset of fatigue cracking and structural failure.

Possible Causes:

- Poor joint construction or location. Joints are generally the less dense areas of a pavement. Therefore, they should be constructed outside of the wheel path so that they are only infrequently loaded. Joints in the wheel path will general fail prematurely.

- A reflective crack from an underlying layer (not including joint reflection cracking)

- HMA fatigue (indicates the onset of future fatigue cracking)

- Top-down is cracking

Repair: Strategies depend upon the severity and extent of the cracking:

- Low severity cracks (< 1/2 inch wide and infrequent cracks). Crack seal to prevent (1) entry of moisture into the subgrade through the cracks and (2) further raveling of the crack edges. HMA can provide years of satisfactory service after developing small cracks if they are kept sealed.

- High severity cracks (> 1/2 inch wide and numerous cracks). Remove and replace the cracked pavement layer with an overlay.

8- Patching

Description: An area of pavement that has been replaced with new material to repair the existing pavement. A patch is considered a defect no matter how well it performs.

Problem: Roughness

Possible Causes:

- Previous localized pavement deterioration that has been removed and patched

- Utility cuts

Repair: Patches are themselves a repair action. The only way they can be removed from a pavement surface is by either a structural or non-structural overlay.

9- Polished Aggregate

Description: Areas of HMA pavement where the portion of aggregate extending above the asphalt binder is either very small or there are no rough or angular aggregate particles.

Problem: Decreased skid resistance

Possible Causes: Repeated traffic applications. Generally, as a pavement age the protruding rough, angular particles become polished. This can occur quicker if the aggregate is susceptible to abrasion.

Repair: Apply a skid-resistant slurry seal, BST or non-structural overlay.

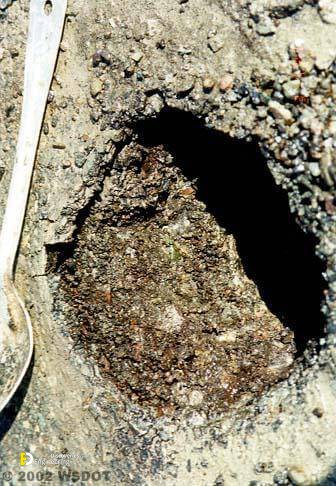

10- Potholes

Description: Small, bowl-shaped depressions in the pavement surface that penetrate all the way through the HMA layer down to the base course. They generally have sharp edges and vertical sides near the top of the hole. Potholes are most likely to occur on roads with thin HMA surfaces (1 to 2 inches) and seldom occur on roads with 4 inch or deeper HMA surfaces .

Problem: Roughness (serious vehicular damage can result from driving across potholes at higher speeds), moisture infiltration

Possible Causes: Generally, potholes are the end result of fatigue cracking. As fatigue cracking becomes severe, the interconnected cracks create small chunks of pavement, which can be dislodged as vehicles drive over them. The remaining hole after the pavement chunk is dislodged is called a pothole.

Repair: In accordance with patching techniques.

11- Raveling

Description: The progressive disintegration of an HMA layer from the surface downward as a result of the dislodgement of aggregate particles.

Problem: Loose debris on the pavement, roughness, water collecting in the raveled locations, resulting in vehicle hydroplaning, loss of skid resistance

Possible Causes:

- Loss of bond between aggregate particles and the asphalt binder as a result of:

- Asphalt binder aging. Aging is generally associated with asphalt binder oxidation as it gets older. As the asphalt binder gets older, oxygen reacts with its constituent molecules resulting in a stiffer, more viscous material that is more likely to lose aggregates on the pavement surface as they are pulled away by traffic.

- A dust coating on the aggregate particles that forces the asphalt binder to bond with the dust rather than the aggregate

- Aggregate segregation. If fine particles are missing from the aggregate matrix, then the asphalt binder is only able to bind the remaining coarse particles at their relatively few contact points.

- Inadequate compaction during construction. High density is required to develop sufficient cohesion within the HMA. Often, inadequate compaction will also result in rutting because once the pavement is opened to traffic, it will continue to compact in the wheelpaths under traffic loading.

- Mechanical dislodging by certain types of traffic (studded tires, snowplow blades or tracked vehicles).

Repair: A raveled pavement should be investigated to determine the root cause of failure. Repair strategies generally fall into one of two categories:

- Small, localized areas of raveling. Remove the raveled pavement and patch. If the pavement is still structurally sound, the raveling can be fixed with a fog seal or slurry seal.

- Large raveled areas indicative of general HMA failure. Remove the damaged pavement and overlay.

12- Rutting

Description: Surface depression in the wheelpath. Pavement uplift (shearing) may occur along the sides of the rut. Ruts are particularly evident after a rain when they are filled with water. There are two basic types of rutting: mix rutting and subgrade rutting. Mix rutting occurs when the subgrade does not rut yet the pavement surface exhibits wheelpath depressions as a result of compaction/mix design problems. Subgrade rutting occurs when the subgrade exhibits wheelpath depressions due to loading. In this case, the pavement settles into the subgrade ruts causing surface depressions in the wheelpath.

Problem: Ruts filled with water can cause vehicle hydroplaning, can be hazardous because ruts tend to pull a vehicle towards the rut path as it is steered across the rut.

Possible Causes: Permanent deformation in any of a pavement’s layers or subgrade usually caused by consolidation or lateral movement of the materials due to traffic loading. Specific causes of rutting can be:

- Insufficient compaction of HMA layers during construction. If it is not compacted enough initially, HMA pavement may continue to densify under traffic loads.

- Subgrade rutting (e.g., as a result of inadequate pavement structure)

- Improper mix design or manufacture (e.g., excessively high asphalt content, excessive mineral filler, insufficient amount of angular aggregate particles)

Repair: A heavily rutted pavement should be investigated to determine the root cause of failure (e.g. insufficient compaction, subgrade rutting, poor mix design or studded tire wear). Slight ruts (< 1/3 inch deep) can generally be left untreated. Pavement with deeper ruts should be leveled and overlayed.

13- Slippage Cracking

Description: Crescent or half-moon shaped cracks generally having two ends pointed into the direction of traffic.

Problem: Allows moisture infiltration, roughness

Possible Causes: Braking or turning wheels cause the pavement surface to slide and deform. The resulting sliding and deformation is caused by a low-strength surface mix or poor bonding between the surface HMA layer and the next underlying layer in the pavement structure.

Repair: Removal and replacement of affected area.

14- Stripping

Description: The loss of bond between aggregates and asphalt binder that typically begins at the bottom of the HMA layer and progresses upward. When stripping begins at the surface and progresses downward it is usually called raveling.

Problem: Decreased structural support, rutting, shoving/corrugations, raveling, or cracking (fatigue and longitudinal)

Possible Causes: Bottom-up stripping is very difficult to recognize because it manifests itself on the pavement surface as other forms of distress including rutting, shoving/corrugations, raveling, or cracking. Typically, a core must be taken to positively identify stripping as a pavement distress. Stripping is typically caused by:

- Poor aggregate surface chemistry

- Water in the HMA causing moisture damage

Repair: A stripped pavement should be investigated to determine the root cause of failure (i.e., how did the moisture get in?). Generally, the stripped pavement needs to be removed and replaced after correction of any subsurface drainage issues.

15- Transverse (Thermal) Cracking

Description: Cracks perpendicular to the pavement’s centerline or laydown direction. Usually a type of thermal cracking.

Problem: Allows moisture infiltration, roughness

Possible Causes:

- Shrinkage of the HMA surface due to low temperatures or asphalt binder hardening.

- Reflective crack caused by cracks beneath the surface HMA layer

- Top-down cracking

Repair: Strategies depend upon the severity and extent of the cracking:

- Low severity cracks (< 1/2 inch wide and infrequent cracks). Crack seal to prevent (1) entry of moisture into the subgrade through the cracks and (2) further raveling of the crack edges. HMA can provide years of satisfactory service after developing small cracks if they are kept sealed.

- High severity cracks (> 1/2 inch wide and numerous cracks). Remove and replace the cracked pavement layer with an overlay.

16- Water Bleeding and Pumping

Description: Water bleeding occurs when water seeps out of joints or cracks or through an excessively porous HMA layer. Pumping occurs when water and fine material is ejected from underlying layers through cracks in the HMA layer or out the sides of the HMA layer under moving loads.

Problem: Decreased skid resistance, an indication of high pavement porosity (water bleeding), decreased structural support (pumping)

Possible Causes:

- Porous pavement as a result of inadequate compaction during construction or poor mix design

- High water table

- Poor drainage

Repair: Water bleeding or pumping should be investigated to determine the root cause. If the problem is a high water table or poor drainage, subgrade drainage should be improved. If the problem is a porous mix (in the case of water bleeding) a fog seal or slurry seal may be applied to limit water infiltration.