The main component of flexible road construction and protective asphalts is “bitumen”. Bitumen comes in a variety of types. A specific type can be chosen depending on the application in each project. In this article, we only mention the types of bitumen that are used in road construction and its repair work.

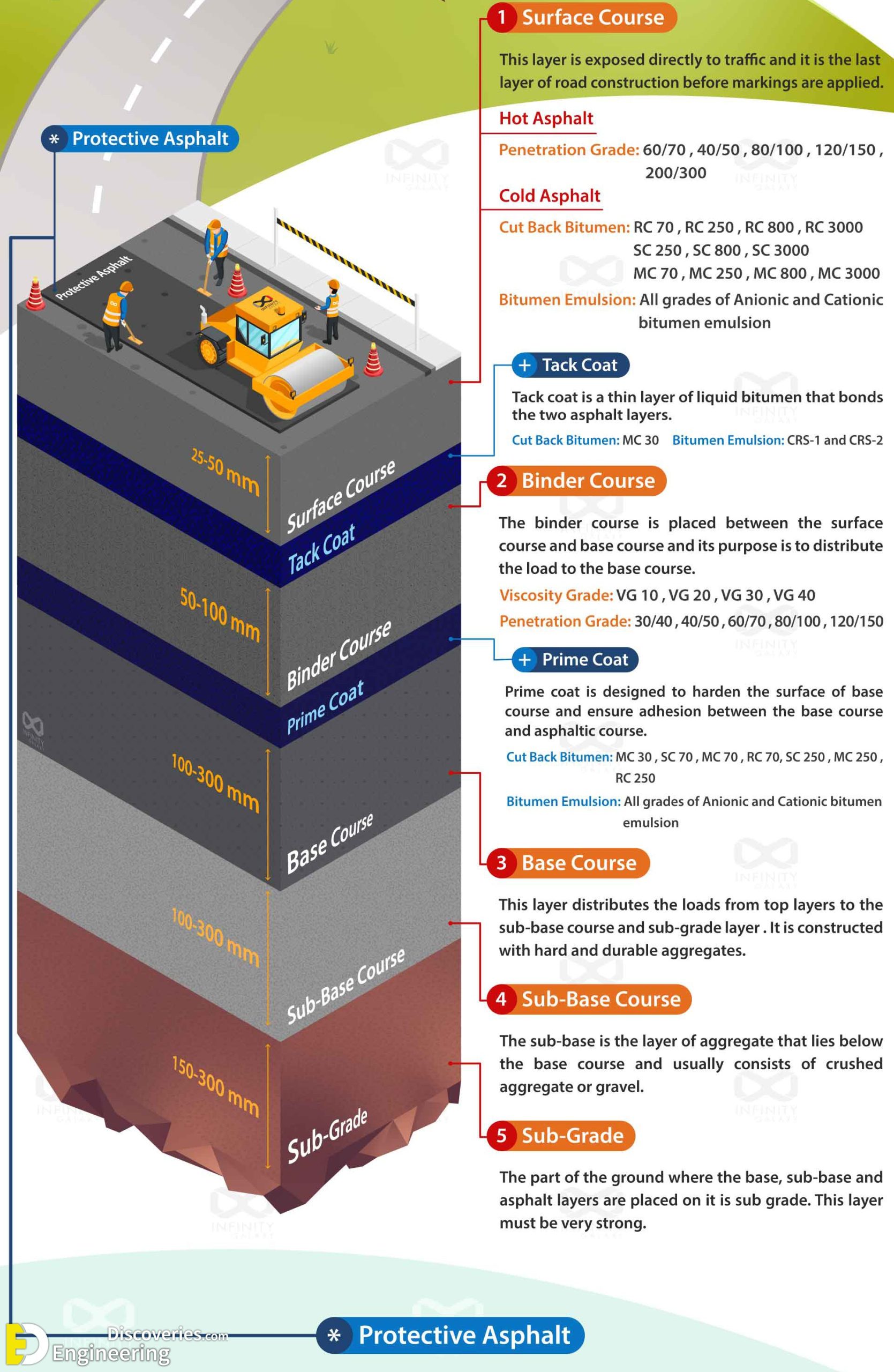

Flexible Pavement includes 3 main layers that are “Surface course”, “Base course”, and “Sub-base” course. The surface course is a layer of bitumen that is mixed with aggregates. The main layers of flexible pavement are stuck together with bituminous sub-course layers which are “Tack coat” and “Prime coat”.

After the completion of road construction, with the passage of time, the top layer of the road slowly erodes. In pavements that are built based on principles, erosion takes place later. In different periods of asphalt life, a series of bituminous coatings can be used to increase the life of the road. According to the type of erosion, this reconstruction can contain aggregate or not. In order to have a better understanding of the subject, let’s learn more about these applications and the bitumen used in them.

Before that visit the below infographic which mentions different types and grades of bitumen in construction and repair works.

Bitumen Types Used in Road Construction

Road Construction

To construct flexible pavement, the below layers must be built in order from bottom to top.

1. Sub Grade

The Subgrade is a part of the ground on which asphalt layers are placed. This layer must be strong enough because it is the base of the entire road layer. It must be able to tolerate the traffic loads and tensions.

2. Sub-base Course

This layer is the roadbed. It is used when the soil of that area is not able to bear the traffic load of the road surface and the expected stresses.

3. Base Course

The base course is a combination of hard and flexible aggregates that must bear the traffic load and distribute it to the lower layers.

4. Prime Coat

After applying for the base course, a thin layer of liquid bitumen is poured which is called the prime coat. Prime coating stabilizes the base course material. It also leads to the binder course sticking well to the base course. Bitumens used in this layer include cutback bitumen and bitumen emulsion.

4. Binder Course

A Binder course is a layer including aggregates and bitumen. This layer has less bitumen than the surface course and fewer quality materials than the base course. The course Binder can be combined with the surface course if there is no budget restriction. Depending on the traffic and weather condition all types of pure bitumen can be used such as viscosity bitumen and penetration bitumen.

6. Surface Course

The last layer of asphalt is the surface course. It must be built with high-quality materials and sufficient bitumen because it is directly exposed to erosion and forces. According to the amount of traffic and temperature changes the suitable pure bitumen is applied on the surface. Therefore, we can have hot or cold asphalt. Hot asphalt is a mixture of aggregates and hot pure bitumen which can be penetration grade bitumen, viscosity grade bitumen, etc. For cold mix asphalt, cutback and bitumen emulsion (liquid bitumens) are used.

Protective Asphalts

Protective asphalt is a thin bituminous layer with or without aggregates. It can make the roadbed impermeable, increase its strength and maintain the road surface from damage, and repairs it. For preparing protective asphalt different grades of liquid bitumen are used.

Different types of protective asphalt are:

- Seal Coat

- Slurry Seal

- Chip Seal

- Micro Surfacing

- Fog Seal

Source: Infinity Galaxy

Click Here To See How To Calculate Asphalt Quantity For Road