Construction is a field where precision, durability, and safety are paramount. Selecting the right concrete grade and steel bars plays a critical role in ensuring a structure’s stability and longevity. In this comprehensive guide, we will delve into the minimum grades of concrete used for different types of construction and discuss the types of steel bars along with their specific applications.

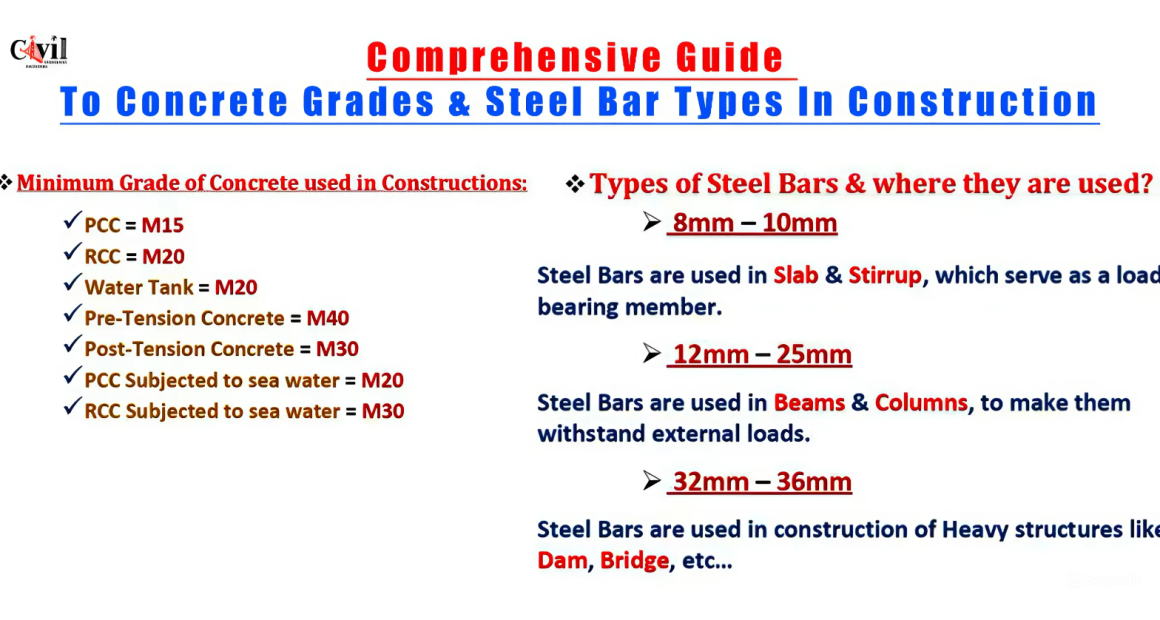

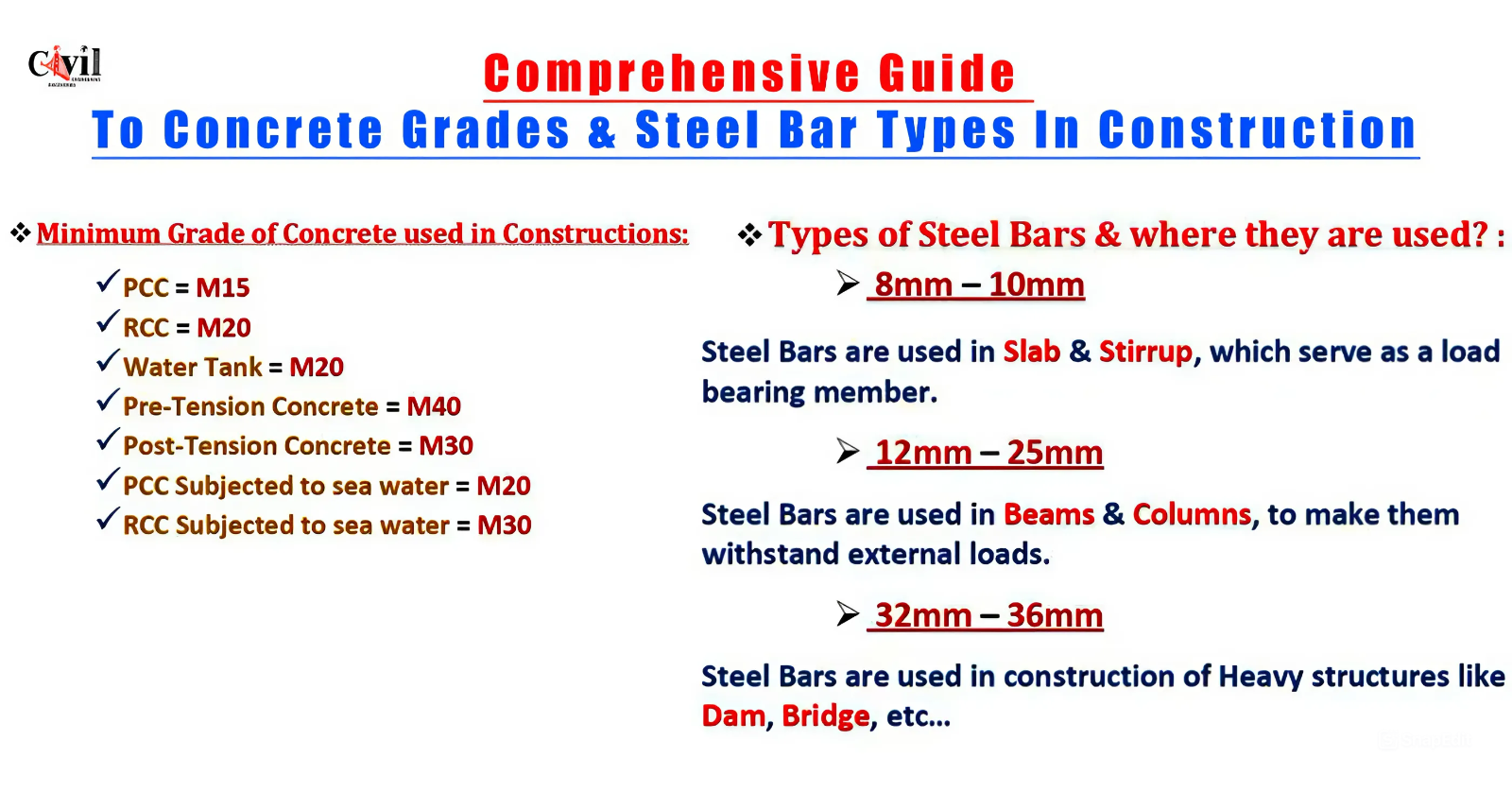

Minimum Grades of Concrete for Different Applications

Concrete grades represent the compressive strength of the mix, measured in megapascals (MPa) after 28 days of curing. The appropriate grade ensures the required strength and durability for each construction component. Below is a detailed guide on the minimum concrete grades used in various structures:

Plain Cement Concrete (PCC) – M15

- PCC is primarily used for simple, unreinforced concrete applications like pavements and base layers.

- It provides a smooth, leveled surface for foundation work.

Reinforced Cement Concrete (RCC) – M20

- RCC combines concrete with reinforcement bars (rebars) to handle tensile stresses.

- It is widely used for beams, slabs, and columns.

Water Tanks – M20

- M20 concrete is ideal for water tanks due to its strength and water-resistant properties.

- This grade ensures structural integrity under water pressure.

PCC Subjected to Sea Water – M20

- Exposure to sea water demands a concrete mix that can resist corrosion and salt damage.

- M20 is the recommended minimum grade.

Post-Tension Concrete – M30

- Post-tension concrete structures require M30 grade for added flexibility and strength.

- Common applications include bridges, large slabs, and elevated structures.

RCC Subjected to Sea Water – M30

- Structures built near or in sea environments require M30-grade concrete for enhanced corrosion resistance.

- This grade helps combat the aggressive marine environment.

Pre-Tension Concrete – M40

- M40 concrete is used in high-stress applications like pre-tensioned beams and girders.

- Its high compressive strength makes it suitable for heavy loads.

Types of Steel Bars and Their Applications

Steel bars, or reinforcement bars or rebars, provide tensile strength to concrete structures. The appropriate diameter and steel bar type are chosen based on the structural requirements.

8mm to 10mm Steel Bars

- Application: Used in slabs and stirrups as load-bearing members.

- These bars help in forming the skeletal structure of concrete components and handle lighter loads.

12mm to 25mm Steel Bars

- Application: Widely used in beams and columns to withstand external loads and structural stress.

- These bars form the primary reinforcement in structural members.

32mm to 36mm Steel Bars

- Application: Ideal for heavy structures like dams and bridges.

- They provide immense tensile strength and stability for large-scale infrastructure.

Importance of Selecting the Right Concrete Grade and Steel Bar Type

Choosing the correct combination of concrete grade and steel bar diameter is essential for:

- Structural Integrity: Ensures the building can withstand various stresses and loads.

- Durability: Protects the structure from environmental factors such as corrosion and weathering.

- Cost Efficiency: Prevents overuse or underuse of materials, optimizing project expenses.

- Safety: Minimizes the risk of structural failures, ensuring the safety of occupants.

Click Here To See Understanding Segregation And Bleeding In Concrete For Durable Structures