Terms You Should Know:

- post-tensioning: a pre-stressing technique where steel strands are tensioned after the concrete is cast

- pre-stressed: concrete that undergoes internal stresses from reinforcing steel strands to offset tension stress of future loads

- pre-tensioning: a pre-stressing technique where steel strands are tensioned prior to the concrete being cast

- rebar: nickname for a reinforcing bar that is used to increase the tensile strength of concrete

- reinforcing bar (rebar): steel rods, strands, or metal fabric placed in concrete slabs, beams, or columns to increase their strength

- reinforced concrete (RC): a composite of two materials: concrete and reinforcing steel (bars and mesh) using the best of both properties

Mechanics of Materials

The mechanics of materials refers to the behavior of materials under stress, with concrete being a common structural component in commercial buildings. Concrete responds well to compressive stress but poorly to tensile stress, making it a brittle material. Reinforcement is used to improve its strength, as concrete resists compressive stress and provides strength against tensile stress.

Concrete expands or stretches when subjected to tensile stress and shrinks or shortens when subjected to compressive stress.

Without reinforcement, concrete experiences brittle fracture as a mode of failure, which is a tensile mode of failure. Reinforcement in concrete changes the brittle fracture mode of failure to ductile fracture, allowing cracks to become visible before complete loss of strength. Concrete alone is not a good structural material, as it is subject to significant tensile stress and varied loads. Therefore, all concrete is reinforced to resist applied tensile forces and control tension cracking under load.

Reinforced Concrete

Reinforced concrete (RC) is a blend of concrete and reinforcing steel, such as bars and mesh, embedded into the concrete to resist applied forces. This method, also known as conventional or regular reinforcement, is crucial for constructing structures.

Conventional reinforcement is a passive method where reinforcing steel doesn’t resist tension until it stretches. This means concrete must crack before steel can withstand tensile stress. Cracking activates the steel’s strength, allowing for the deflection of concrete that’s manageable. Reinforcing steel is typically placed at the top and bottom of slabs.

Conventionally reinforced concrete may also be augmented with pre-tensioning or post-tensioning steel rebar strands. When these techniques are implemented, the material is collectively referred to as pre-stressed concrete. This is a form of active reinforcement, which, as the name implies, means that the concrete is pre-stressed before being placed in service. It is pre-stressed using stretching (tensioning) steel rebar strands.

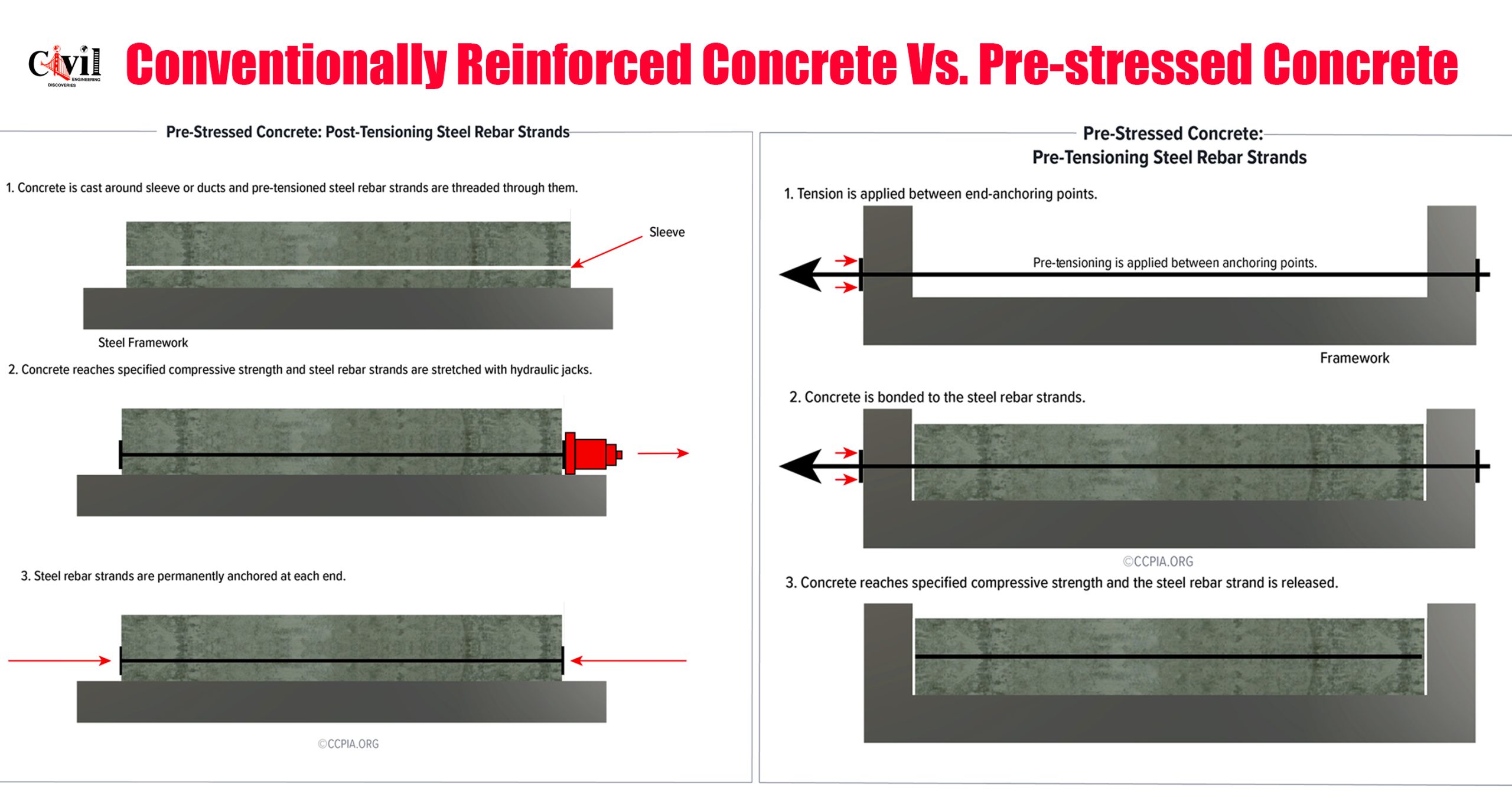

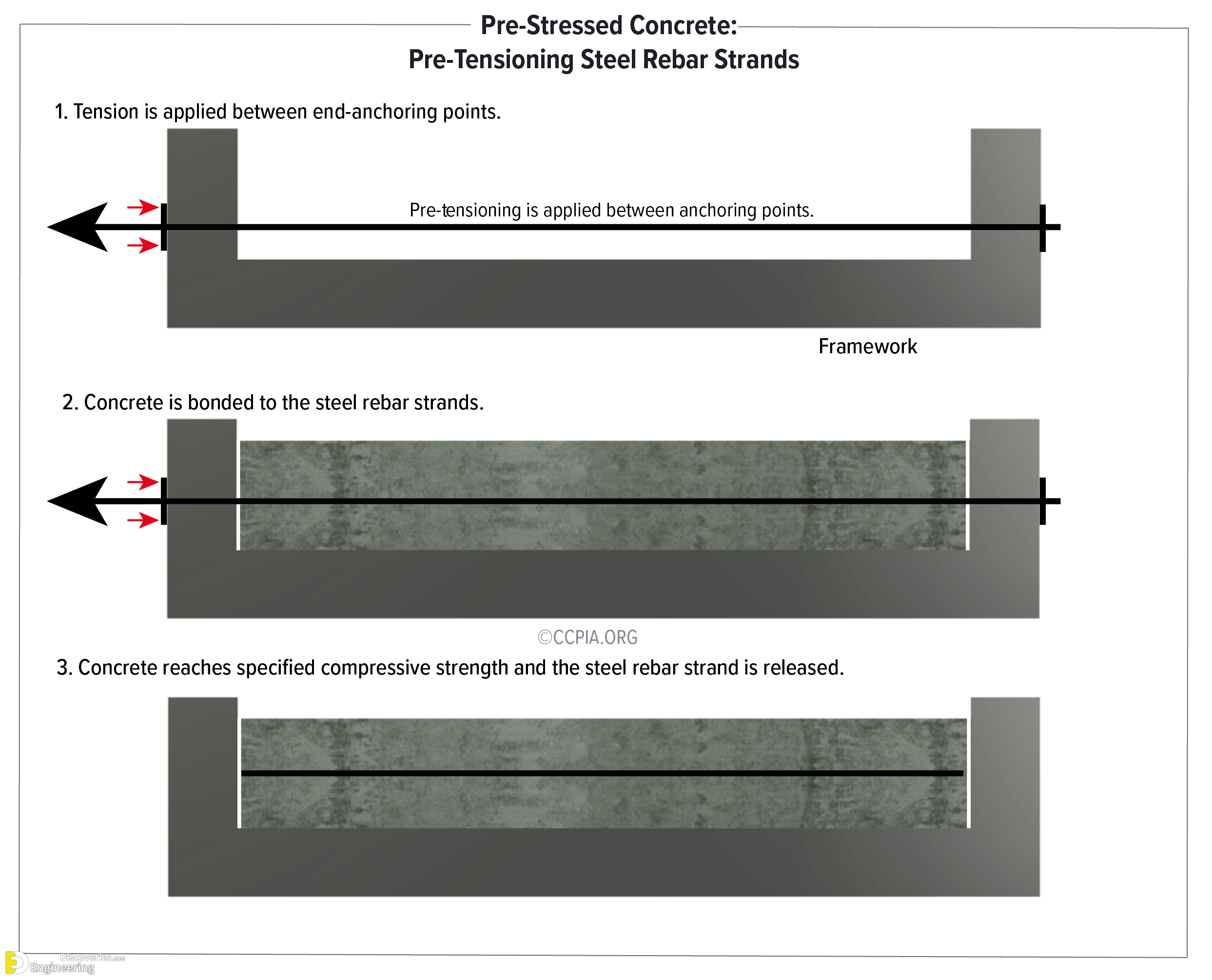

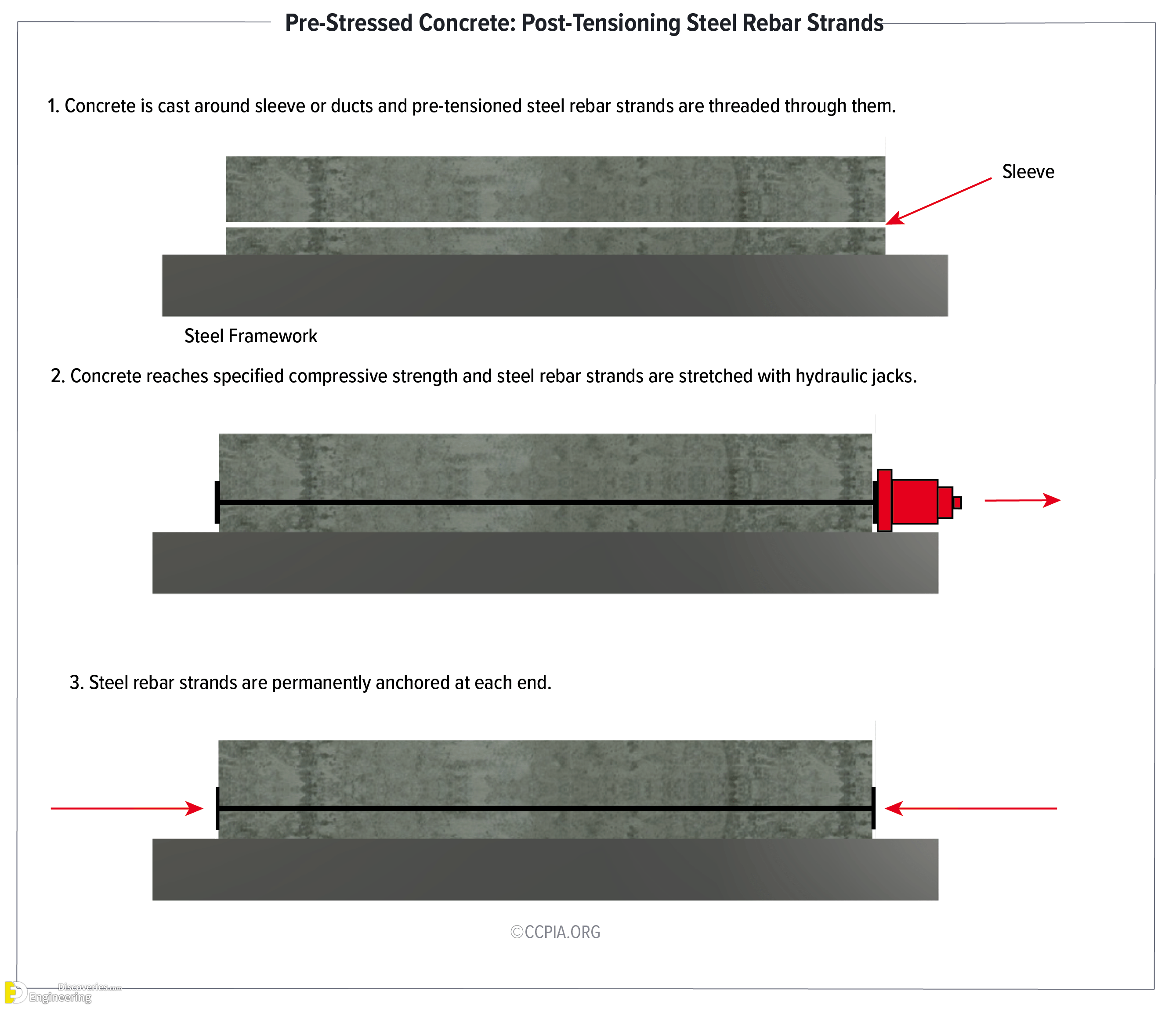

The two pre-stressing techniques are described below:

1. Pre-tensioning: The concrete is cast around pre-tensioned steel rebar strands. These strands are stretched across a concrete framework between two end-anchoring points. The concrete is bonded to the steel strands, and once the concrete reaches a specified compressive strength, the steel rebar strands are released. In this technique, once the concrete cures and the pre-tensioning steel rebar strands are released, the tension is transferred inside the concrete as compression through friction with the reinforcement.

2. Post-tensioning: The concrete is cast around sleeves or ducts, and the pre-tensioning steel rebar strands are threaded through them. Once the concrete reaches a specified compressive strength, the steel rebar strands are stretched with hydraulic jacks and permanently anchored at each end. The sleeves or tubes are usually filled with grout. Post-tensioning is also achieved by giving steel rebar strands the freedom to move within the concrete to some degree. In this case, the steel rebar strand is greased with corrosion-resistant lubricant and insheathing. This is referred to as unbonded post-tensioning. In this technique, permanent compression is applied to the concrete when the steel rebar strand is permanently anchored.

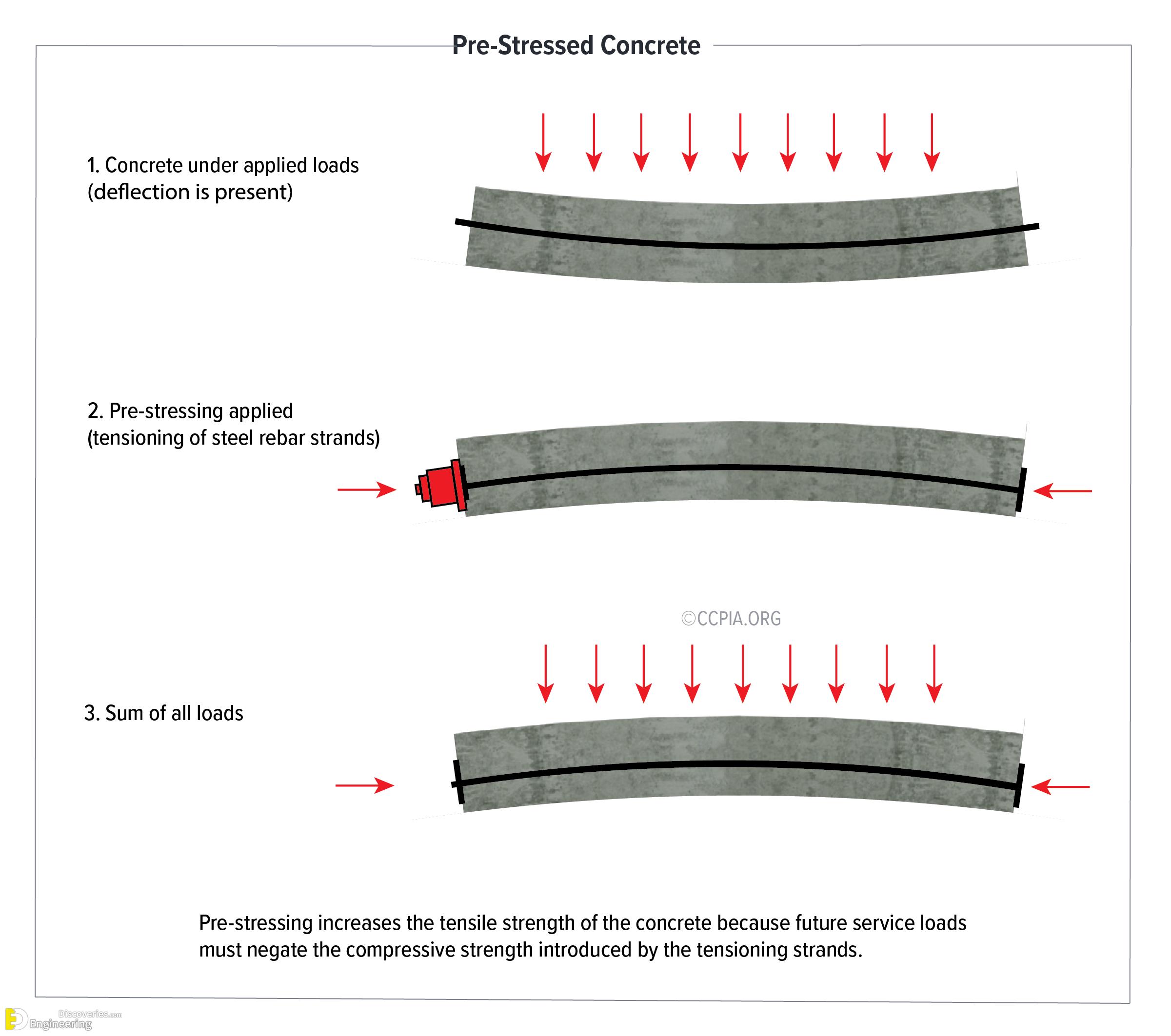

In both pre-stressing techniques, the stretching of the strands is a form of stressing that compresses the concrete. This, in turn, introduces internal stresses that counter the tension stress from future service loads. To sum up, pre-stressing increases the tensile strength of the concrete because future service loads must negate the compressive pre-stress. Pre-stressed concrete is often incorporated into civil engineering projects, like bridge decks, as well as at the following elements of commercial buildings: balconies, lintels, floor slabs, beams, foundation plies, and parking structures.

Common Reinforced Concrete Defects

Cracks are a common and visible defect in reinforced concrete, which can affect the structural integrity of the elements. There are two types: plastic settlement, which forms above steel reinforcement, and corrosion of reinforcement, which forms above reinforcement. These defects can appear within hours of the concrete’s curing process or take years to develop. Inspectors should report cracking signs based on their location and characteristics.