What is a Crank Bar?

A Crank Bar is an essential reinforcement technique in civil engineering used to strengthen structural components like beams and slabs under flexural stress. This technique enhances the structure’s durability by providing steel reinforcement in tension zones.

Purpose of Crank Bar

The primary purpose of crank bars is to provide reinforcement where the structure experiences tension due to bending moments. It helps in:

- Resisting negative (hogging) moments at supports.

- Bearing high shear forces at beam ends.

- Reducing the risk of brittle failure.

- Minimizing the quantity of steel required makes the structure economical.

Design of Crank Bar

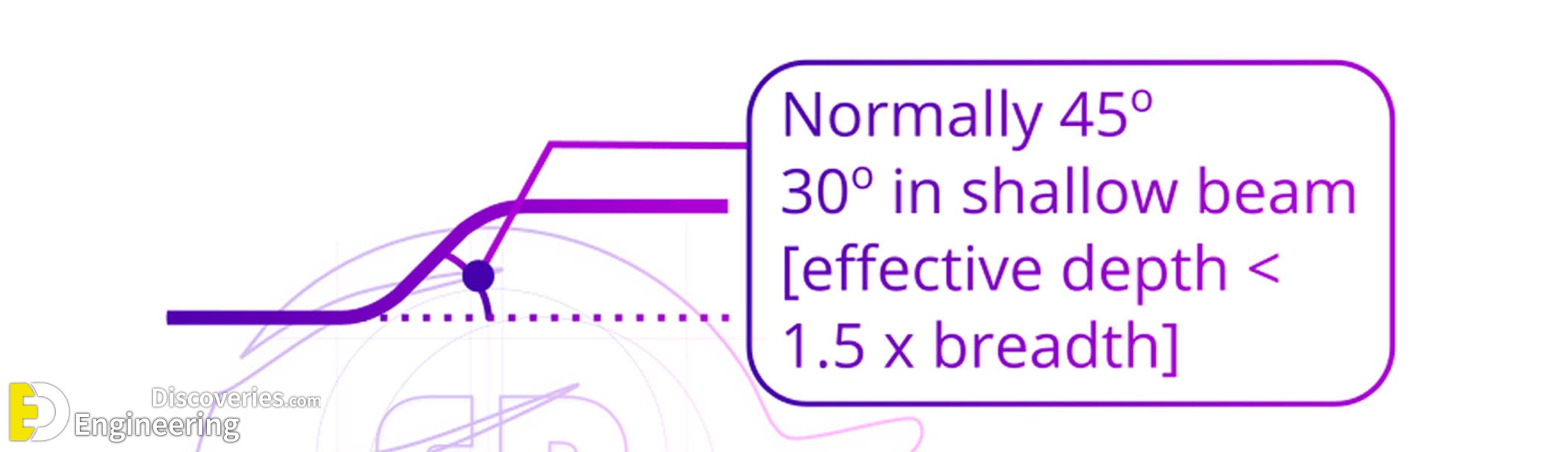

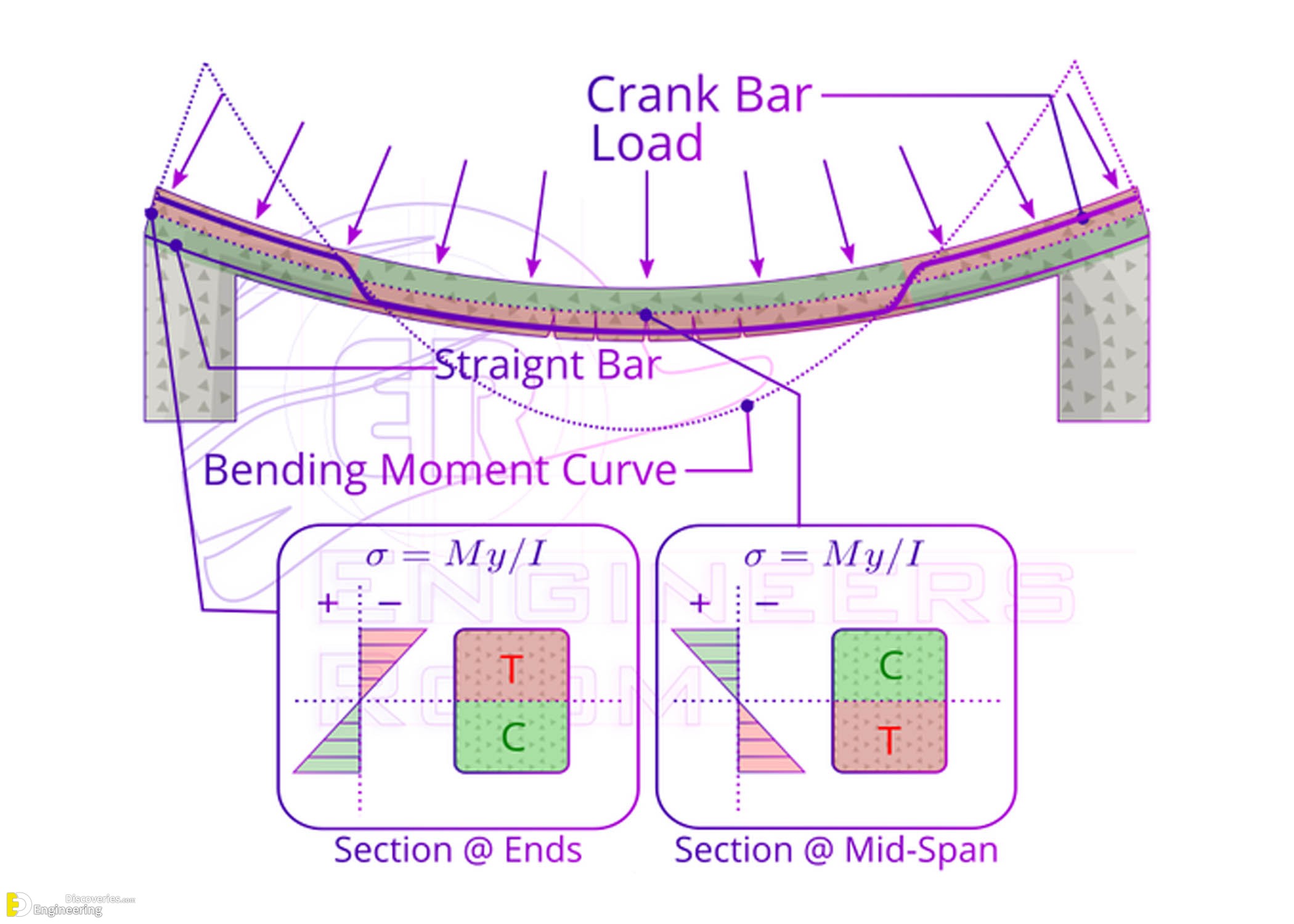

Crank bars are usually bent at an angle of 45° or 30° in shallow beams (with an effective depth less than 1.5 times the breadth). The bend is applied near the supports, where negative bending moments are dominant, while the mid-span remains straight to handle positive bending moments.

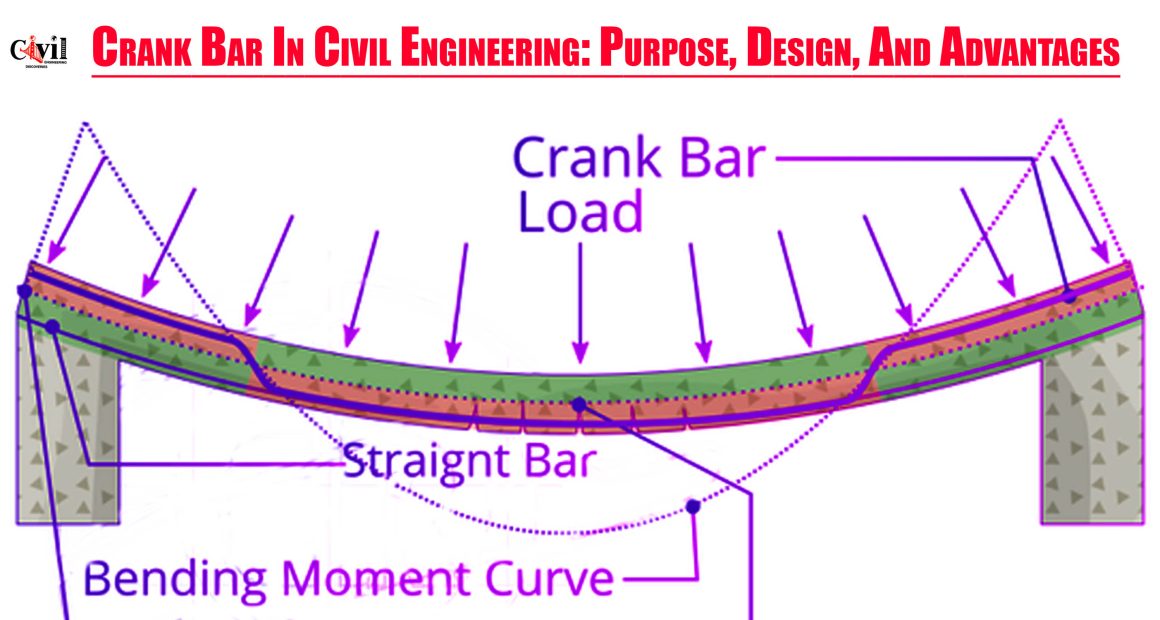

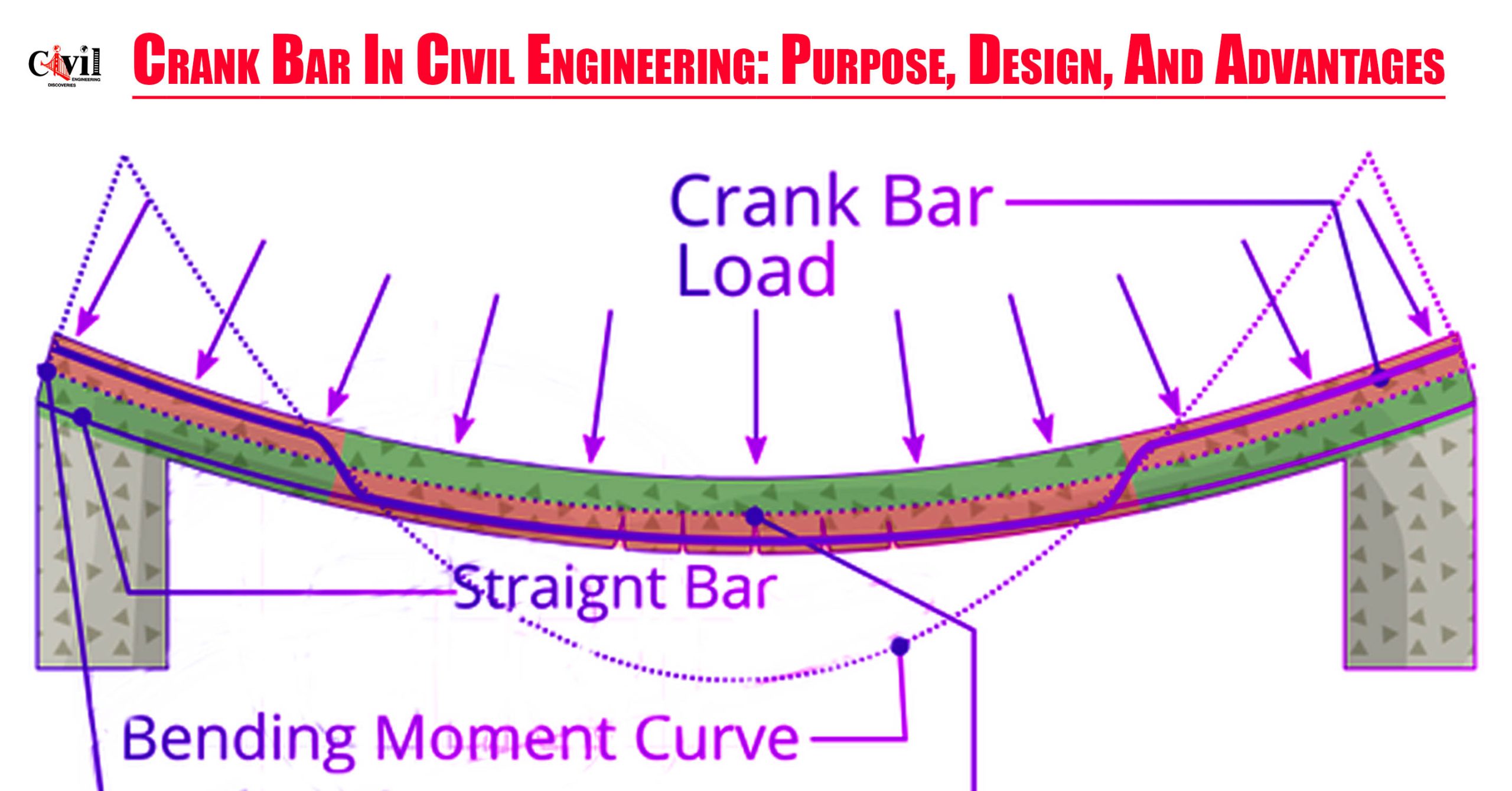

Bending Moment and Crank Bar Placement

- At supports, the top portion of the beam is in tension, requiring crank bars to provide reinforcement.

- At mid-span, the bottom portion is in tension, where straight bars are sufficient.

- The crank bar’s shape follows the bending moment curve, ensuring steel is present where tension occurs.

Advantages of Crank Bar

- Improves the strength and stability of beams and slabs.

- Enhances the load-bearing capacity of structures.

- Reduces steel consumption, making the design more cost-effective.

- Prevents cracking and brittle failure in tension zones.

- Ensures the structure can withstand the reversal of moments effectively.

Conclusion

The Crank Bar is a smart and economical method to reinforce beams and slabs, ensuring the structure can resist both positive and negative bending moments. Its strategic placement and design not only enhance the strength but also optimize the use of materials, making it a sustainable solution in civil engineering.

Click Here To See Understanding Concrete Footing Shear Failure And Reinforcement

Very good