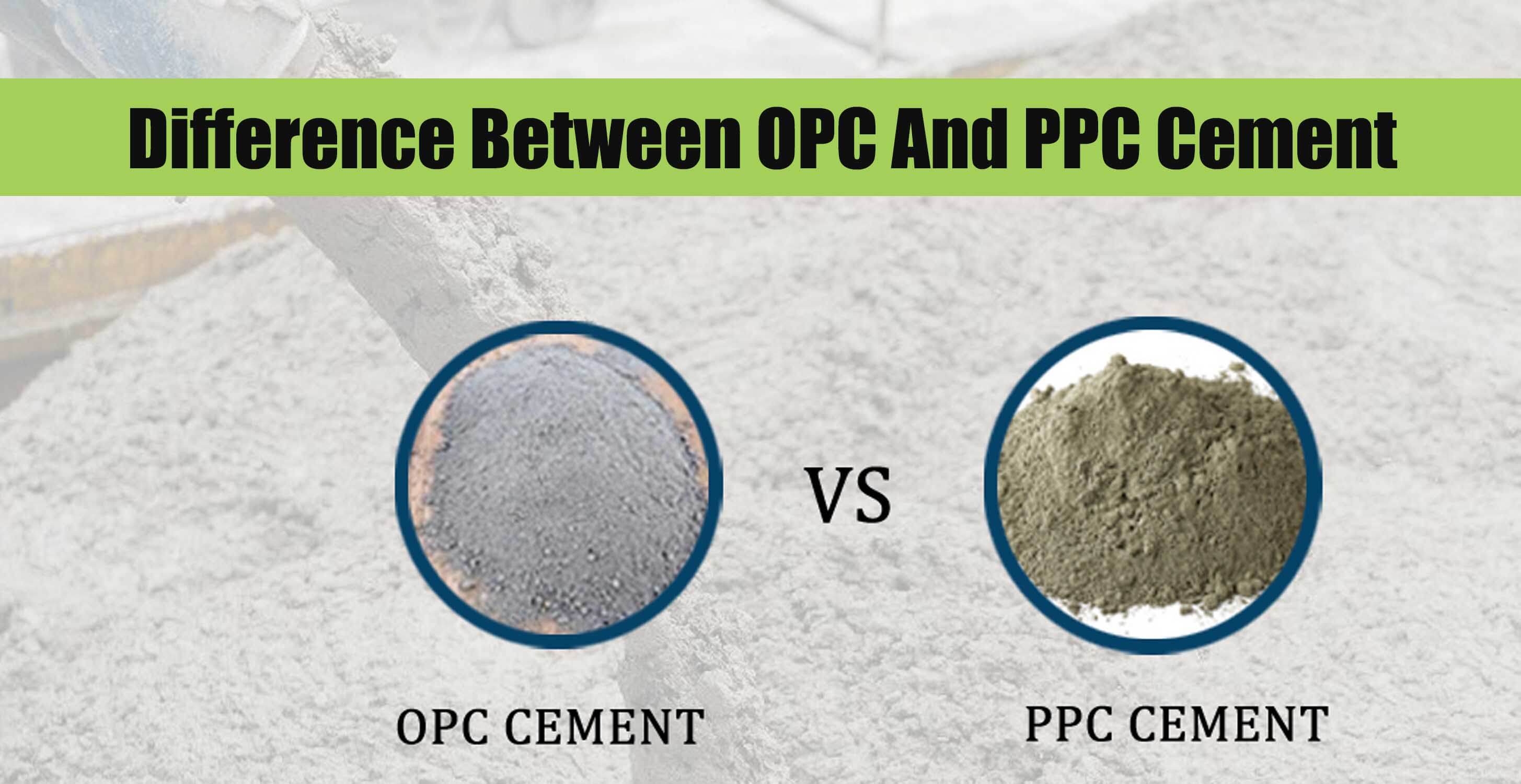

Cement is the most important material used in constructions as it binds the rest of the building materials together and ensures the strength and durability of the structure. There are two main types of cement available, and choosing the right type of cement determines the quality of the construction. There has been a lot of debate around OPC vs PPC and which one of the both is more suitable for a specific construction. This article helps you in finding out what are the differences between OPC and PPC, and which type of cement is better for your construction project.

Ordinary Portland Cement (OPC)

OPC has been the most common type of cement used for years due to its abundance and low production cost. OPC is produced by grinding limestone and secondary materials to fine powder. Compared to PPC, OPC usually takes little time for setting, which is important for large scale constructions, thus speeding up the process of determining the length of the construction period.

In addition to the quick setting time, OPC also takes very little time for curing. Curing period is the time taken by concrete to get settled completely and maintain the moisture for hydration reaction to occur normally so that concrete develops hardened properties over time. Curing plays a crucial role in determining the structural integrity of the construction. OPC, in turn, is classified into three grades: OPC 33 Grade, OPC 43 Grade, and OPC 53 Grade. The Grade number is the respective compressive strength (in MPa) achieved after 28 days of curing.

Portland Pozzolana Cement (PPC)

PPC is a variation of OPC. Pozzolana materials such as fly ash, calcined clay, and volcanic ash are added to OPC, and the result leads to PPC. Pozzolana materials are added to the cement in the ratio of 15% to 35% by weight. PPC is available in one grade and its strength is similar to that of OPC 33 Grade after curing.

Difference Between OPC and PPC Cement

| S.No. | Ordinary Portland Cement ( OPC ) | Portland Pozzolana Cement ( PPC ) |

| 1. | OPC is prepared by a completely automated dry production process by grinding argillaceous, calcareous material to gypsum. | PPC is produced by inter-grinding well- burned clinkers with gypsum and pozzolana materials such as fly ash or silica power plants. |

| 2 | In OPC permeability is more than PPC. | Higher durability of the concrete structure due to less permeability than OPC. |

| 3 | The heat of hydration is higher than PPC | The heat of hydration is lower than OPC so can be used in mass concreting and eliminates surface cracks. |

| 4 | OPC is available in three grades, 33grade,43grade and 53 grade. | There is no grade available in PPC. |

| 5 | Fly ash can be mixed for design mix to reduce the cost of concrete. | Fly ash cannot be used if using PPC cement. |

| 6 | The curing period is less than PPC hence curing cost reduces. | More curing days are required due to the slow heat of hydration. |

| 7. | The initial strength of OPC is higher than PPC. | The strength of PPC is better than OPC in the long term with proper curing. |

| 8 | OPC is not favourable in aggressive weather. | PPC is favourable in aggressive weather. |

| 9 | OPC is costlier than PPC. | PPC is cheaper than OPC. |