There are two different processes for manufacturing cement. wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder-like substance. Both the processes are in use and have their own advantages and disadvantages. While in wet process grinding is easier, in the dry process there is a saving in fuel costs involved in drying up the slurry.

Wet process

1- Mixing of Raw materials in wash mill with 35 to 50% water.

2- Materials exiting the mill are called “slurry” and have flowability characteristics.

3- Size of the kiln needed for the manufacturing of cement is bigger.

4- Raw material can be mixed easily, so a better homogeneous material can be obtained

5- Fuel consumption is high i.e., 350 kg of coal per tonne of cement produced.

6- Cost of production is high.

7- Capital cost (Cost of establishment) is comparatively less.

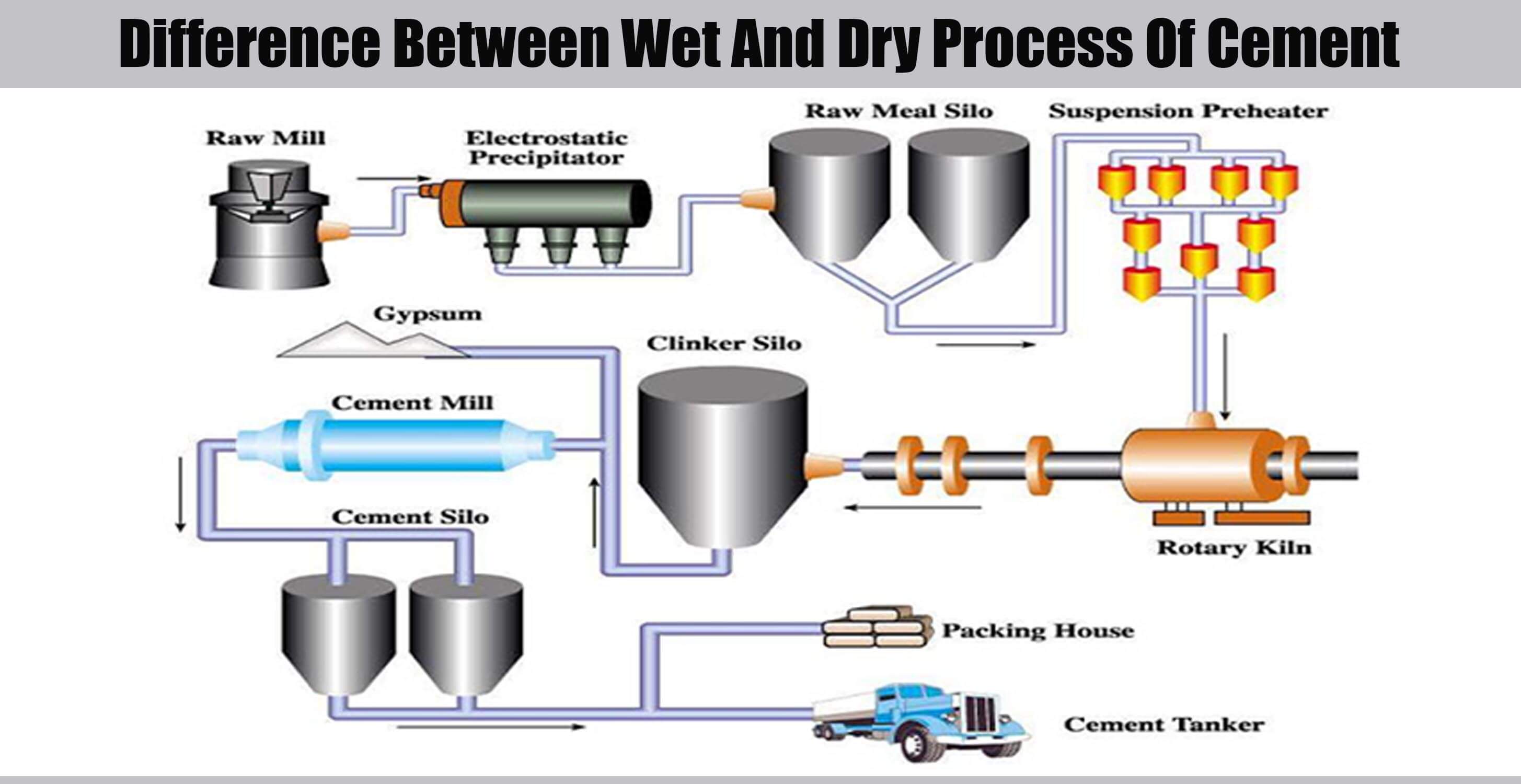

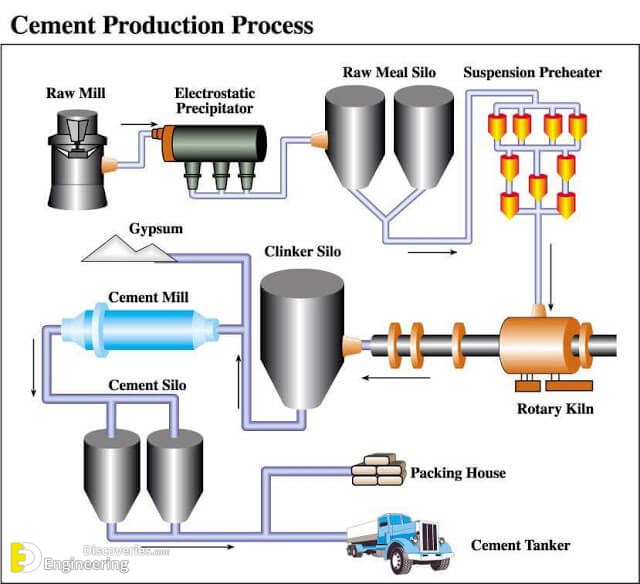

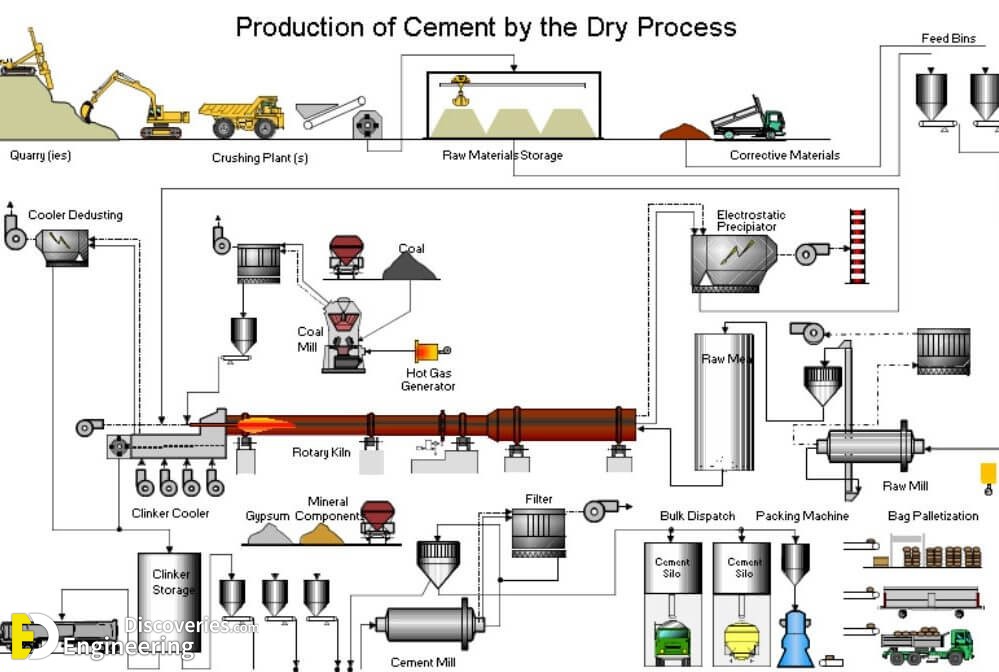

Dry process

1- Mixing of raw material in a dry state in blenders.

2- The dry materials exiting the mill are called “kiln feed”.

3- Size of the kiln needed for the manufacturing of cement is smaller.

4- Difficult to control mixing of Raw materials, so it is difficult to obtain a better homogeneous material.

5- Fuel consumption is low i.e., 100 kg of coal per tonne of cement produced.

6- Cost of production is less.

7- Capital cost is high due to blenders.

Which one is better?

If we consider the quality and Rate then wet process is better and if we consider fuel consumption and time of process then the dry process is better.

Difference between dry and wet process in table form

Dry process | Wet process |

| 1. Mixing of raw material in a dry state in blenders. | 1. Mixing of Raw materials in wash mill with 35 to 50% water. |

| 2. The dry materials exiting the mill are called “kiln feed”. | 2. Materials exiting the mill are called “slurry” and have flowability characteristics. |

| 3. Fuel consumption is low i.e., 100 kg of coal per tonne of cement produced | 3. Fuel consumption is high i.e., 350 kg of coal per tonne of cement produced |

| 4. Cost of production is less. | 4. Cost of production is high |

| 5. Capital cost is high due to blenders. | 5. Capital cost (Cost of establishment) is comparatively less |

| 6. Size of the kiln needed for the manufacturing of cement is smaller. | 6. Size of the kiln needed for the manufacturing of cement is bigger. |

| 7. Difficult to control mixing of Raw materials, so it is difficult to obtain a better homogeneous material. | 7. Raw material can be mixed easily, so a better homogeneous material can be obtained |