Foundations provide support to the structure, transfers the loads from the structure to the soil. But the layer at which the foundation transfers the load shall have an adequate bearing capacity and suitable settlement characteristics. There are several types of foundation depending on various considerations such as:

1- Total load from the superstructure.

2- Soil conditions.

3- Water level.

4- Noise and vibrations sensitivity.

5- Available resources.

6- Time-frame of the project.

7- Cost.

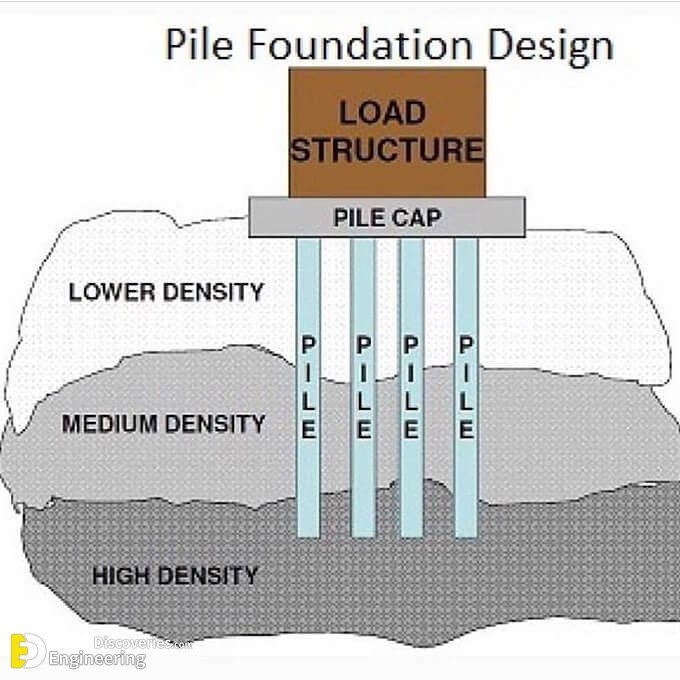

Foundations can be classified as shallow foundations and deep foundations. Shallow footings are usually used when the bearing capacity of the surface soil is adequate to carry the loads imposed by a structure. On the other hand, deep foundations are usually used when the bearing capacity of the surface soil is not sufficient to carry the loads imposed by a structure. So, the loads have to be transferred to a deeper level where the soil layer has a higher bearing capacity.

What is Pile Foundation?

Pile foundation a kind of deep foundation, is actually a slender column or long cylinder made of materials such as concrete or steel which are used to support the structure and transfer the load at desired depth either by end-bearing or skin friction. Pile foundations are usually used for large structures and in situations where the soil at shallow depth is not suitable to resist excessive settlement, resist uplift, etc.

When to Use Pile Foundation

Following are the situations when using a pile foundation system can be

1- When the groundwater table is high.

2- Heavy and un-uniform loads from superstructure are imposed.

3- Other types of foundations are costlier or not feasible.

4- When the soil at shallow depth is compressible.

5- When there is the possibility of scouring, due to its location near the river bed or seashore, etc.

6- When there is a canal or deep drainage system near the structure.

7- When soil excavation is not possible up to the desired depth due to poor soil condition.

8- When it becomes impossible to keep the foundation trenches dry by pumping or by any other measure due to heavy inflow of seepage.

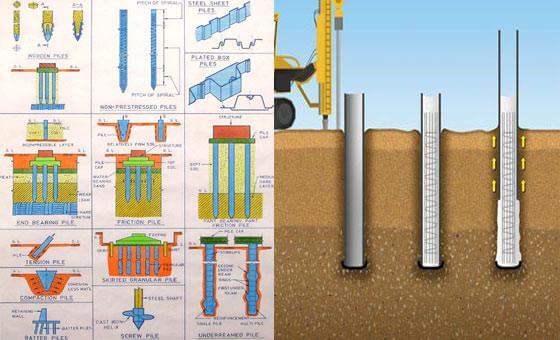

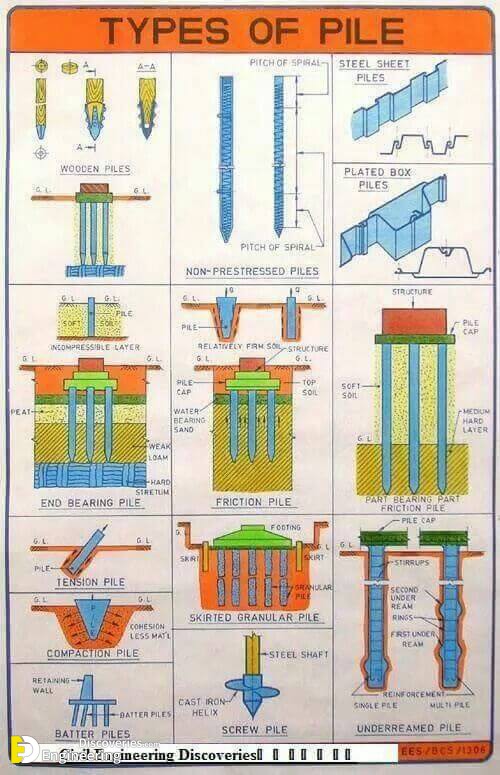

Types of Pile Foundation

Pile foundations can be classified based on function, materials and installation process, etc. Followings are the types of pile foundation used in construction:

1- Based on Function or Use

- Sheet Piles

- Load Bearing Piles

- End bearing piles

- Friction Piles

- Soil Compactor Piles

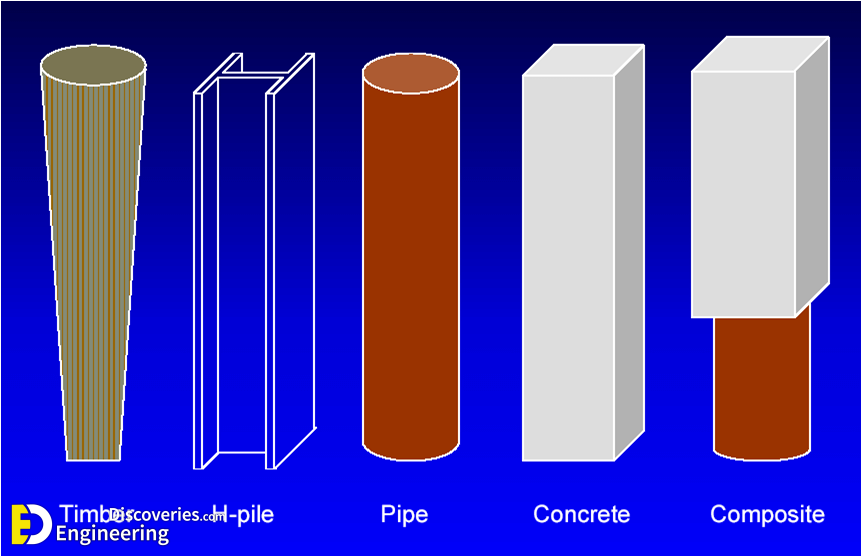

2- Based on Materials and Construction Method

- Timber Piles

- Concrete Piles

- Steel Piles

- Composite Piles

Classification of Pile Foundation Based on Function or Use

Sheet Piles

This type of pile is mostly used to provide lateral support. Usually, they resist lateral pressure from loose soil, the flow of water, etc. They are usually used for cofferdams, trench sheeting, shore protection, etc. They are not used for providing vertical support to the structure.

They are usually used to serve the following purpose:

1- Construction of retaining walls.

2- Protection from riverbank erosion.

3- Retain the loose soil around foundation trenches.

4- For isolation of foundation from adjacent soils.

5- For confinement of soil and thus increase the bearing capacity of the soil.

Load Bearing Piles

This type of pile foundation is mainly used to transfer the vertical loads from the structure to the soil. These foundations transmit loads through the soil with poor supporting property onto a layer that is capable of bearing the load. Depending on the mechanism of load transfer from pile to the soil, load-bearing piles can be further classified as flowed.

End Bearing Piles

In this type of pile, the loads pass through the lower tip of the pile. The bottom end of the pile rests on a strong layer of soil or rock. Usually, the pile rests at a transition layer of a weak and strong slayer. As a result, the pile acts as a column and safely transfers the load to the strong layer. The total capacity of the end bearing pile can be calculated by multiplying the area of the tip of the pile and the bearing capacity of that particular depth of soil at which the pile rests. Considering a reasonable factor of safety, the diameter of the pile is calculated.

Friction Pile

Friction pile transfers the load from the structure to the soil by the frictional force between the surface of the pile and the soil surrounding the pile such as stiff clay, sandy soil, etc. Friction can be developed for the entire length of the pile or a definite length of the pile, depending on the strata of the soil. In a friction pile, generally, the entire surface of the pile works to transfer the loads from the structure to the soil.

The surface area of the pile multiplied by the safe friction force developed per unit area determines the capacity of the pile. While designing a skin friction pile, the skin friction to be developed at a pile surface should be sincerely evaluated and a reasonable factor of safety should be considered. Besides this one can increase the pile diameter, depth, number of piles and make the pile surface rough to increase the capacity of the friction pile.

Soil Compactor Piles

Sometimes piles are driven at placed closed intervals to increase the bearing capacity of soil by compacting.

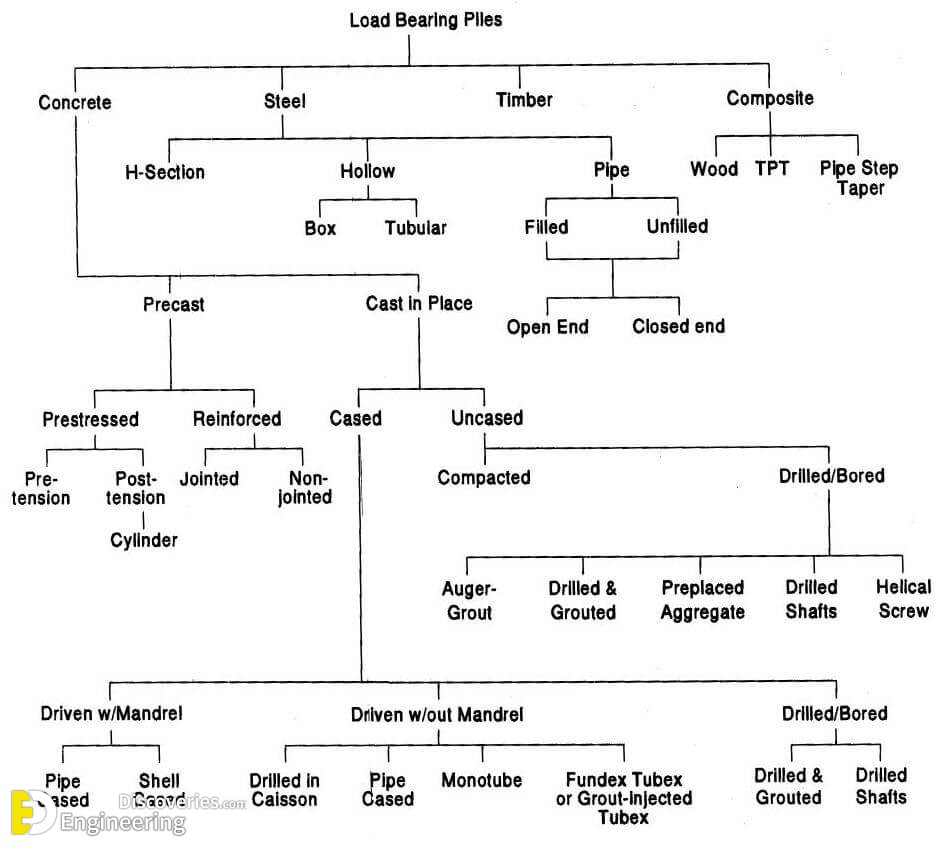

Classification of Piles Based on Materials and Construction Method

Primarily piles can be classified into two parts. Displacement piles and Non-displacement or Replacement piles. Piles that cause the soil to be displaced vertically and radially as they are driven to the ground are known as Displacement piles. In the case of Replacement piles, the ground is bored and the soil is removed and then the resulting hole is either filled with concrete or a pre-cast concrete pile is inserted. On the basis of materials of pile construction and their installation process load-bearing piles can be classified as follows:

- Timber Piles

- Untreated

- Treated with Preservative

- Concrete Piles

- Pre-cast Piles

- Cast-in-place piles

- Steel Piles

- I-Section Piles

- Hollow Piles

- Composite Piles

Timber Piles

Timber piles are placed underwater level. They last for approximately about 30 years. They can be rectangular or circular in shape. Their diameter or size can vary from 12 to 16 inches.

The length of the pile is usually 20 times the top width. They are usually designed for 15 to 20 tons. Additional strength can be obtained by bolting fish plates to the side of the piles.

Advantages of Timber Piles

1- Timber piles of regular size are available.

2- Economical.

3- Easy to install.

4- Low possibility of damage.

5- Timber piles can be cut off at any desired length after they are installed.

6- If necessary, timber piles can be easily pulled out.

Disadvantages of Timber Piles

1- Piles of longer lengths are not always available.

2- It is difficult to obtain straight piles if the length is short.

3- It is difficult to drive the pile if the soil strata are very hard.

4- Spicing of timber pile is difficult.

5- Timber or wooden piles are not suitable to be used as end-bearing piles.

6- For the durability of timber piles, special measures have to be taken. For example- wooden piles are often treated with preservatives.

Concrete Piles

Pre-cast Concrete Pile

This type of piles is cast in pile bed in the horizontal form if they are rectangular in shape. Usually, circular piles are cast in vertical forms. Precast piles are usually reinforced with steel to prevent breakage during their mobilization from the casting bed to the location of the foundation. After the piles are cast, curing has to be performed as per specification. Generally curing period for pre-cast piles is 21 to 28 days.

Advantages of Pre-cast Piles

1- Provides high resistance to chemical and biological cracks.

2- They are usually of high strength.

3- To facilitate driving, a pipe may be installed along the center of the pile.

4- If the piles are cast and ready to be driven before the installation phase is due, it can increase the pace of work.

5- The confinement of the reinforcement can be ensured.

6- The quality of the pile can be controlled.

7- Any fault is identified, it can be replaced before driving.

8-Pre-cast piles can be driven under the water.

9- The piles can be loaded immediately after it is driven up to the required length.

Disadvantages of Pre-cast Piles

1- Once the length of the pile is decided, it is difficult to increase or decrease the length of the pile afterward.

2- They are difficult to mobilize.

3- Needs heavy and expensive equipment to drive.

4- As they are not available for ready-made purchase, it can cause a delay of the project.

5- There is a possibility of breakage or damage during handling and driving piles.

Cast-in-Palace Concrete Piles

This type of pile is constructed by boring soil up to the desired depth and then, depositing freshly mixed concrete in that place and letting it cure there. This type of pile is constructed either by driving a metallic shell to the ground and filling it with concrete and leave the shell with the concrete or the shell is pulled out while concrete is poured.

Advantages of Cast-in-Place Concrete Piles

1- The shells are light weighted, so they are easy to handle.

2- The length of piles can be varied easily.

3- The shells may be assembled at sight.

4- No excess enforcement is required only to prevent damage from handling.

5- No possibility of breaking during installation.

6- Additional piles can be provided easily if required.

Disadvantages of Cast-in-Place Concrete Piles

1- Installation requires careful supervision and quality control.

2- Needs sufficient place on-site for storage of the materials used for construction.

3- It is difficult to construct cast in situ piles where the underground water flow is heavy.

4- The bottom of the pile may not be symmetrical.

5- If the pile is un-reinforced and uncased, the pile can fail in tension if there acts and uplifting force.

Steel Piles

Steel piles may be of I-section or hollow pipe. They are filled with concrete. The size may vary from 10 inches to 24 inches in diameter and thickness is usually ¾ inches. Because of the small sectional area, the piles are easy to drive. They are mostly used as end-bearing piles.

Advantages of Steel Piles

1- They are easy to install.

2- They can reach a greater depth compared to any other type of pile.

3- Can penetrate through the hard layer of soil due to the less cross-sectional area.

4- It is easy to splice steel piles.

5- Can carry heavy loads.

The disadvantage of Steel Piles

1- Prone to corrosion.

2- Has a possibility of deviating while driving.

3- Comparatively expensive.

Pile Installation Methods

In pile foundations, the Installation process and methods of installation are equally important as the design process. During the design of piles, the installation method and equipment should be carefully selected in order to avoid damages to the pile.

Pile driving methods (displacement piles)

1- Dropping weight: A hammer with approximately the weight of the pile is raised to a suitable height and is released to strike the pile head.

2- Vibration: The amplitude of vibration used here should be sufficient to break the skin friction on the sides of the pile. This is best suited for sandy or gravelly soils.

3- Jacking (only for micro piles): To install jacking piles, Hydraulic rams are used to push piles into the ground

4- Jetting: To aid the penetration of piles into sand or sand gravel, water jetting can be employed.

Boring methods (non-displacement piles)

Continuous flight auger (CFA): If boring and pouring take place simultaneously during pile driving, then they are called CFA piles. Here the equipment comprises of a mobile base carrier fitted with a hollow main flight auger which is rotated and driven into the ground to get the required depth of piling. This method is especially effective on soft ground.

Underreaming: This is a special type of auger bored pile which is used to exploit the bearing capacity of respective strata by providing an enlarged base. The soil should be capable of standing open unsupported to employ this technique.

Negative skin friction

When fill or load is placed on compressible soil deposit, consolidation takes place. When the piles are driven through the soil deposit before consolidation is complete, the soil will move downward relative to the pile. The downward movement of the soil develops skin friction between the pile and the surrounding soil and it’s termed as negative skin friction. It can also be developed from lowering the water level in compressible soils such as clay, mud, and soft soil and also due to an increase in stress.