Introduction

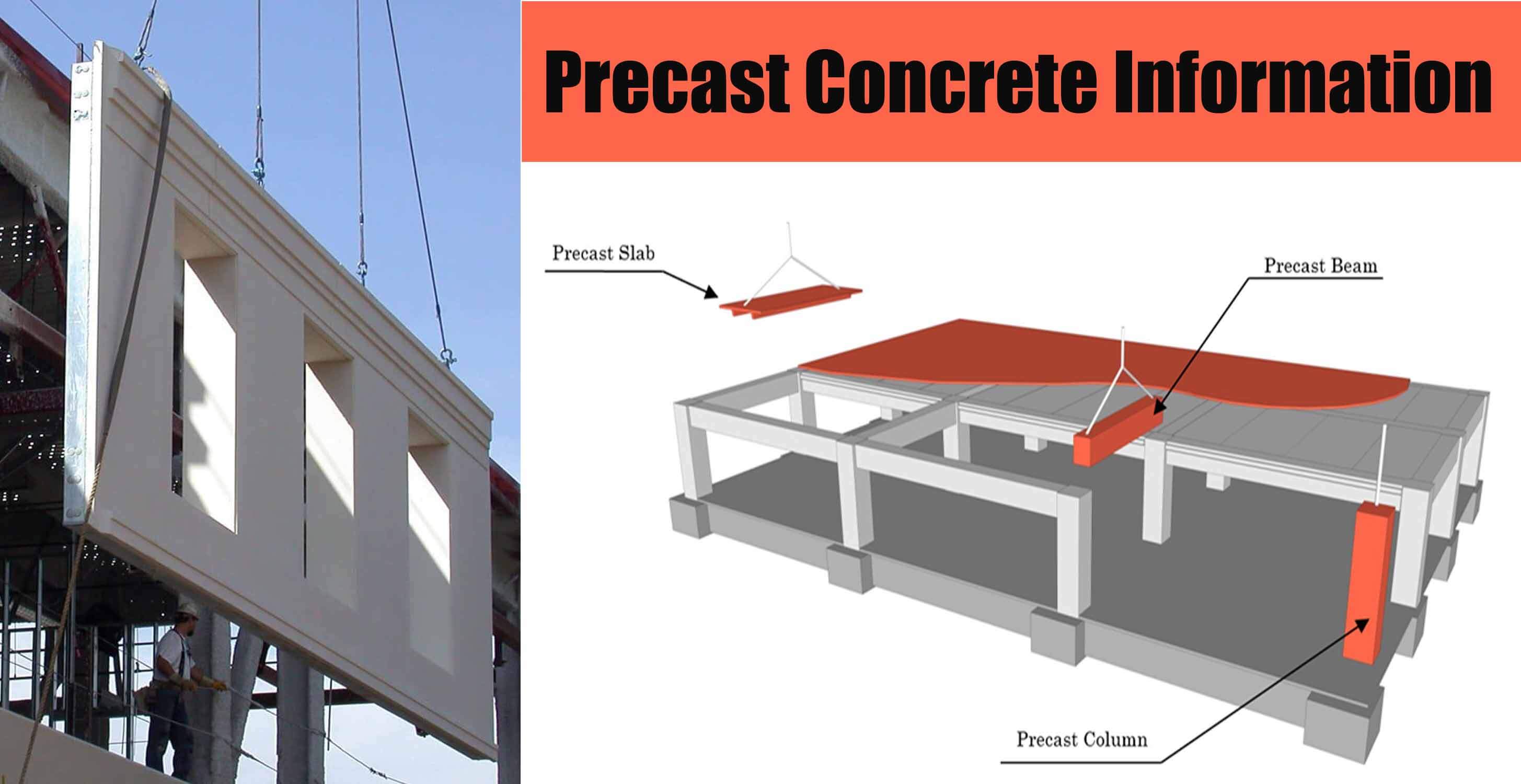

Precast concrete is a form of concrete that is prepared, cast and cured off-site, usually in a controlled factory environment, using reusable moulds. Precast concrete elements can be joined to other elements to form a complete structure. It is typically used for structural components such as;

wall panels, beams, columns, floors, staircases, pipes, tunnels, and so on. Structural steel frames can provide an alternative for pre-fabricated structural components, but precast concrete can be more economical and sometimes more practical. Many buildings now include a mixture of both construction techniques, sometimes incorporating structural steelwork, in-situ concrete and precast concrete elements.

Manufacturing process

The production of precast concrete elements takes place under controlled conditions in enclosed factories. This means that tolerances can be accurately controlled, waste can be minimised, and that a denser, stronger and better quality concrete can be produced. Concrete is cast into forms and left to cure. Precast forms are normally made of steel or plywood. Whereas plywood forms are usually limited to about 20-50 castings depending upon the complexity of the form, a virtually unlimited number of castings can be made by precasting using steel forms.

Precast elements generally incorporate steel reinforcement to resist loading stresses. A common cause of the deterioration of concrete structures is the corrosion of this reinforcement. It is important therefore, that they are properly designed and embedded in the concrete. During the manufacturing process, admixtures can be included in the concrete. These can be water-reducing, air-entraining, retarders and accelerators (for faster curing time).

The purpose of admixtures is to improve concrete quality in both its fresh and hardened state. Colourpigments can also be added, such as iron oxides (red and brown), chrome oxides (green) or cobalt oxides (blue). An alternative form of precasting is prestressed concrete, where stresses are introduced into the structural member during fabrication as a way of improving both its strength and performance. For more information, see Prestressed concrete.

Installation

The on-site installation of precast components can be a high-risk activity involving the use of heavy plant, cranes and personnel working at height. Consideration should be given therefore to safeguarding against risks when receiving delivery, moving, and placing units.

Consideration should be given to:

1- The method and sequence of assembly and erection.

2- The method of providing temporary supports.

3- Structural connections and joint details.

4- Tollerances.

5- Handling and rigging requirements.

6- Site accessibility for delivery and storage.

7- Crane capacity and working clearance for hoisting.

8- Sample measurement to confirm the accuracy of critical dimensions.

9- Visual inspection of concrete finishes for defects.

10- Locations and conditions of lifting inserts for hoisting.

Advantages of using precast concrete include

1- Precast concrete is produced in a factory with advanced construction techniques.

2- The materials used in precast concrete production are easily obtainable.

3- The construction procedure is very fast, which ultimately saves time.

4- It possesses better thermal insulating characteristics.

5- Precast members are totally fire-proof and sound-proof.

6- Precast members are lightweight and can be transported easily to the job site.

7- Formwork is not required in such construction.

8- If necessary, precast members can be separated and reused in other structure.

Disadvantages of precast concrete

1- It requires careful supervision and more skilled workers for producing the members.

2- Uniform spacing between beams are required in the structure, which can become difficult.

3- Some members are broken up and wasted during the time of transportation from the factory to the construction site.

4- The molds that are used for casting are little costly, so the construction will be economical when a lot of members are produced.

For more information watch this video