In the realm of construction, the integrity of structures relies heavily on the reinforcement of materials, particularly in concrete structures. Among the various methods of connecting reinforcing bars (rebars), three prominent techniques stand out: rebar couplers, lapping, and welding. Each method comes with its own set of advantages and disadvantages, catering to different project requirements and considerations.

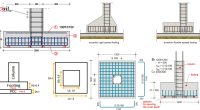

Rebar Couplers

Rebar couplers are mechanical connectors used to join two reinforcement bars without the need for overlapping. These couplers are threaded at both ends and screwed onto the ends of the rebars to create a strong, continuous connection. One of the key advantages of rebar couplers is their ability to maintain the load path integrity, ensuring structural stability. Additionally, they eliminate the need for manual labor involved in lapping, thereby saving time and reducing errors. However, rebar couplers may have higher upfront costs compared to other methods, and their effectiveness can be influenced by factors such as bar alignment and thread quality.

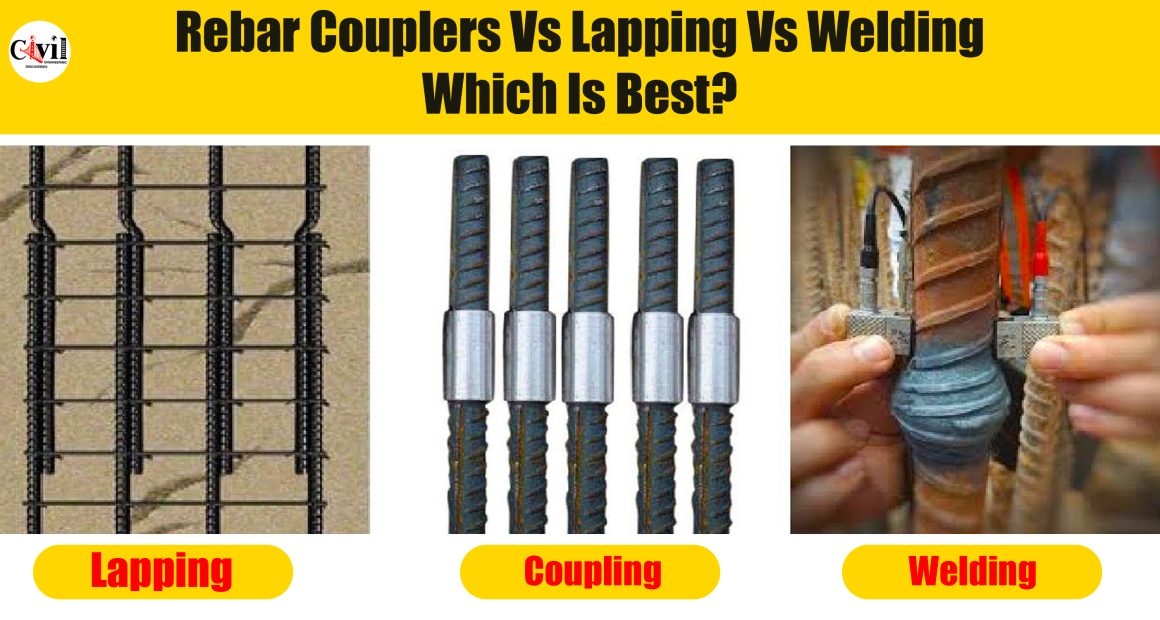

Lapping

Lapping is a traditional method of reinforcement connection that involves overlapping two rebars and securing them with tie wires or steel straps. While lapping is a widely accepted practice and does not require specialized equipment, it has some drawbacks. Lapped joints can be susceptible to corrosion if not properly protected, and the overlapping length can affect the overall aesthetics of the structure. Moreover, lapping requires precise placement and alignment to ensure proper load transfer, which can be labor-intensive and time-consuming.

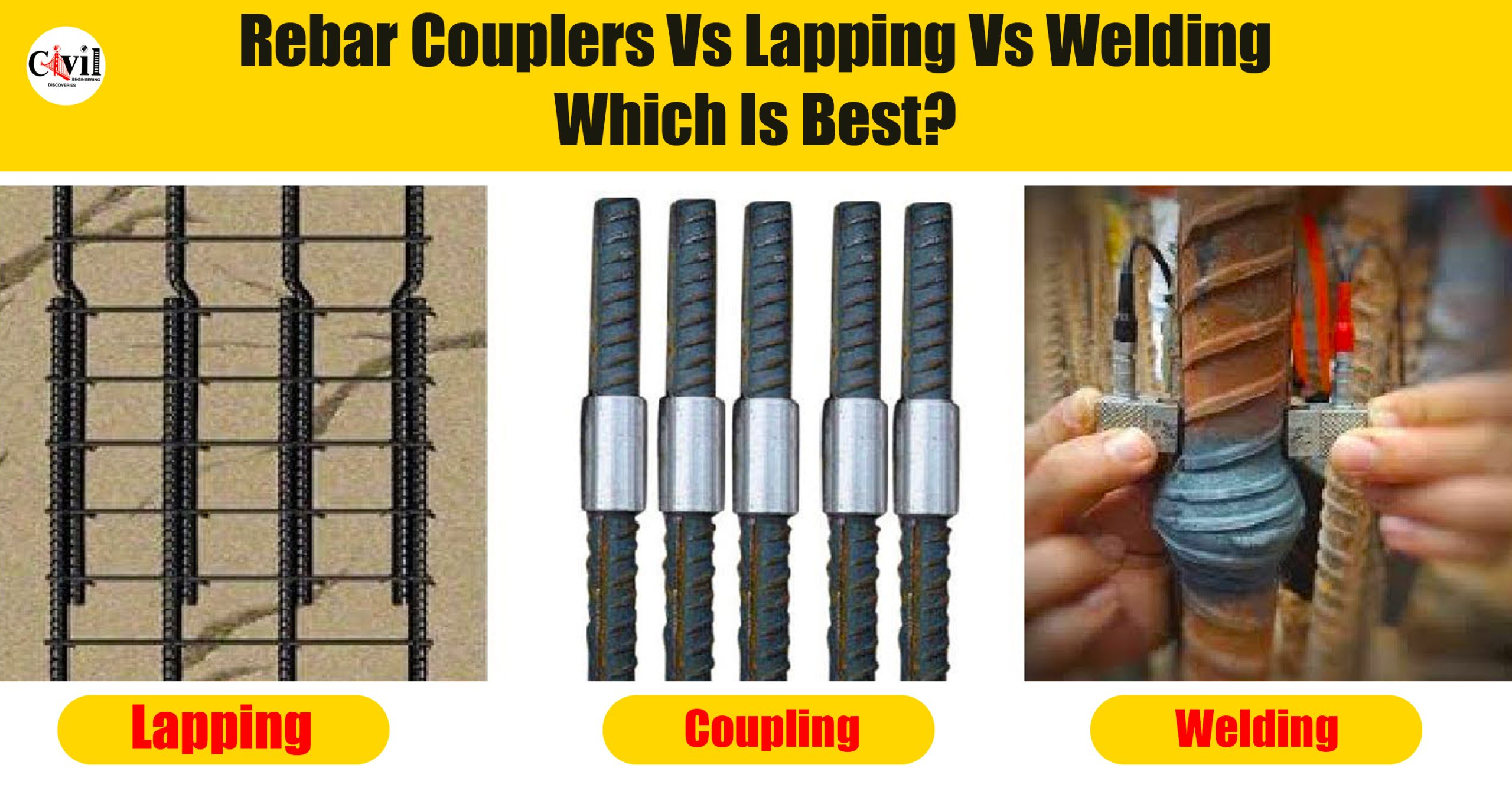

Welding

Welding offers a strong and durable connection between rebars by fusing them together using heat and pressure. Welded joints provide excellent load transfer and structural integrity, making them suitable for high-stress applications. However, welding requires skilled labor and specialized equipment, which can increase project costs. Additionally, welding may produce hazardous fumes and require adequate ventilation and safety measures to protect workers.

Comparison

When comparing rebar couplers, lapping, and welding, several factors come into play:

- Strength and Durability: Welded joints typically offer the highest strength and durability, followed by rebar couplers and lapped joints.

- Installation Time and Complexity: Rebar couplers generally offer the fastest and simplest installation, followed by lapping and welding, which require more time and expertise.

- Cost Effectiveness: Lapping tends to be the most cost-effective method, followed by rebar couplers and welding, which can incur higher material and labor costs.

Application and Suitability

The choice between rebar couplers, lapping, and welding depends on various factors such as project requirements, structural design, and budget constraints. Rebar couplers are ideal for projects with tight schedules and where ease of installation is prioritized. Lapping is suitable for smaller-scale projects or where welding is not feasible due to safety or environmental concerns. Welding is preferred for high-stress applications or when specific design requirements dictate.

Safety Considerations

Regardless of the method chosen, safety should always be a top priority in construction projects. Structural integrity and load-bearing capacity are paramount, and any compromise in reinforcement connections can lead to catastrophic failures. It is essential to adhere to industry standards and regulations regarding the use of rebar couplers, lapping, and welding, and to ensure proper training and supervision of personnel involved in these tasks.

Environmental Impact

In an era of increasing environmental awareness, the sustainability of construction methods is a growing concern. Rebar couplers and lapping generally have lower environmental impact compared to welding, which requires energy-intensive processes and may produce harmful emissions. Choosing environmentally friendly construction methods can contribute to reducing the carbon footprint of projects and promoting sustainable development.

Future Trends

As technology continues to advance, new innovations in reinforcement connection methods are emerging. From the development of self-locking rebar couplers to the use of robotic welding systems, the construction industry is constantly evolving to improve efficiency, safety, and sustainability. Keeping abreast of these developments can help stakeholders make informed decisions and stay ahead of the curve in construction practices.

Case Studies

Real-world examples showcase the practical applications and effectiveness of rebar couplers, lapping, and welding in various construction projects. Case studies provide valuable insights into the performance, cost, and feasibility of each method, helping stakeholders evaluate their suitability for specific scenarios and challenges.

Couplers Vs Lapping Vs Welding

| Coupling | Lapping | Welding | |

| 1. Load Path Continuity | Accurate | Not good | Not good |

| 2. Load Transfer | Great | Depends on concrete | Depends on concrete |

| 3. Structural Integrity | Great | Moderate | Moderate |

| 5. Steel Quantity | Less | Requires extra steel for lapping. | Requires extra steel for welding |

| 6. Rebar Congestion | Rebar couplers do not create congestion | Creates congestion, Difficulty in concrete pouring, and vibration | Creates congestion, Difficulty in concrete pouring, and vibration |

| 7. Splice Calculation | Not required | Required | — |

| 8. Supervising | Easy | Easy | Not easy |

| 9. Quality Control | Great | Moderate | Low to medium |

| 10. Cost | Medium | High | Low |

| 11. Wastages | Minimal | High | High |

| 12. Time | Fast work | Time-consuming | Time-consuming |

| 13. Installation | Very Easy | Easy | Welder Required |

So, from the above comparison, we can see rebar couplers or mechanical splices are far better than lapping or welding. We can use it in any construction effectively.

Click Here To See The Ultimate Guide To Rebar Couplers – Pros, Cons & Different Types!